Whats going on with this mill

| Rainbows | 26/06/2015 17:25:12 |

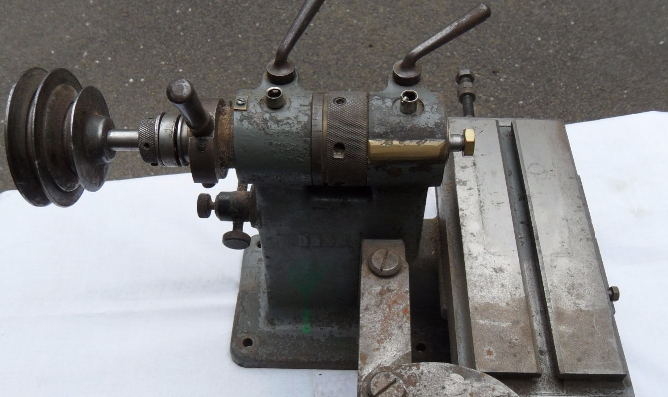

| 658 forum posts 236 photos | After my success with the £5 watchmakers lathe (woops it got sent to a relatives adress instead so that will take another week to get here) I am again cruising through the internets ready to chew bubblegum and get bargains. Aside from 80s movie references here is my question. Through a website other than fleabay this time I have found a small horizontal miller but I must say I can't tell how the chucking works. It has what looks like a collet drawbar on the pulley end but on the other there is just a nut. Can anyone tell what is going on there? Also more generally how useful do you think this would be? Spindle height is apparently adjustable and the table moves by that lever but there isn't an z axis to speak of. I guess it is useful for making surfaces flat or cutting slots but it doesn't posess the over reaching arm of most H millers so I guess it will only achieve light cuts. I'm debating what a good price for it would be.

Finally pictures

|

| Michael Gilligan | 26/06/2015 17:34:54 |

23121 forum posts 1360 photos | Can't be sure from the photos, but I think the bit with the nut on is being held in a collet. What would worry me [and certainly go towards determining the price] is the brassy patch on the front bearing ... it looks very much like a brazed repair of a cracked housing. MichaelG. |

| JasonB | 26/06/2015 17:50:39 |

25215 forum posts 3105 photos 1 articles | Not sure its really a milling machine. I would say the collet allows for quick changing of the actual part not the cutter and a toolpost or two would be mounted on the bed. Quick pull of the lever would do the cutting opperation(s) and then change to the next part and so on, ideal for repetative production work. |

| Michael Gilligan | 26/06/2015 18:05:15 |

23121 forum posts 1360 photos | I beg to differ, Jason It looks [to me] very much like a small [Horological] Horizontal Milling Machine. I would expect the [missing] arbor to fit an 8mm collet, and carry cutters with a 7mm bore. ... Always happy to be proved wrong. MichaelG.

|

| Rainbows | 26/06/2015 18:06:00 |

| 658 forum posts 236 photos | !!!

Now you say so you may be right, I have seen capstan lathes with a similar mechanism. I would have thought a production machine would be heavier built though.

Also he says there is a brazed crack in the headstock does not affect operation. No doubt he is an honorable man and is entirely correct. And re: nut being held in collet. Well sometimes the obvious will just fly over my head.

|

| John Stevenson | 26/06/2015 18:13:28 |

5068 forum posts 3 photos | They used to use these things by the hundreds for slitting screw heads.

As to value if it polishes up, £10 if it doesn't £8 |

| JasonB | 26/06/2015 18:18:48 |

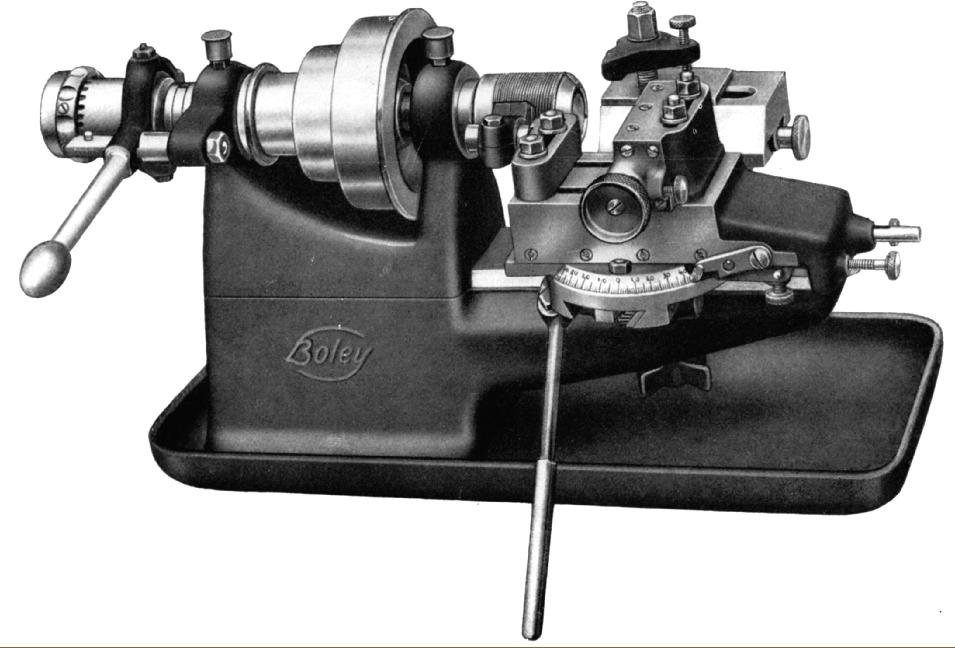

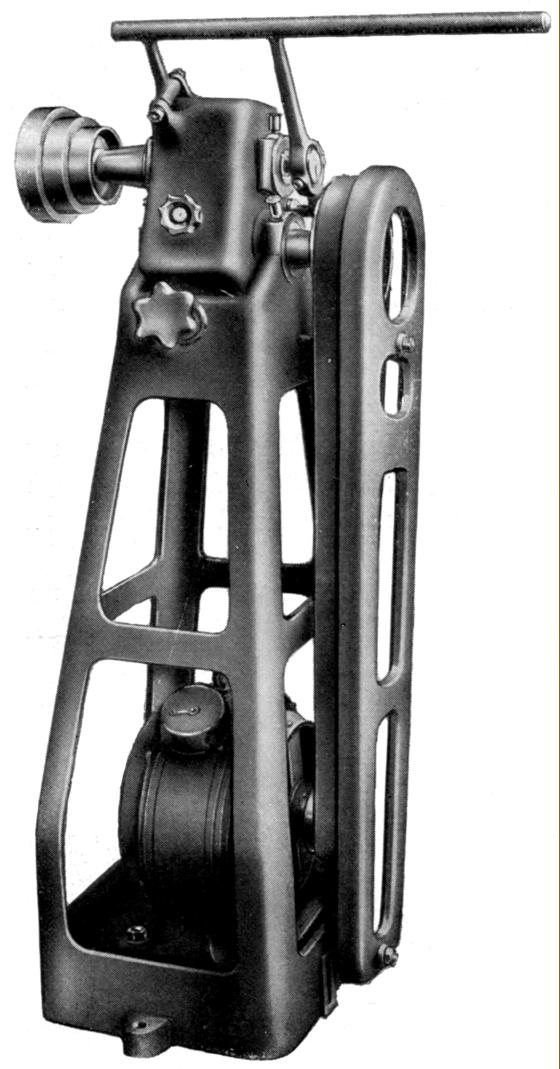

25215 forum posts 3105 photos 1 articles | Simpler version of this Boley, second op or finishing lathe. If you were only making hundreads of small parts why would you need a heavy substantial machine? As for the brass nut could have been the last of the production run that was being faced and/or chamfered

And another

Edited By JasonB on 26/06/2015 18:54:38 |

| Rainbows | 26/06/2015 19:06:50 |

| 658 forum posts 236 photos | Posted by John Stevenson on 26/06/2015 18:13:28:

They used to use these things by the hundreds for slitting screw heads.

As to value if it polishes up, £10 if it doesn't £8

Maybe I should send that to the seller |

| Clive Hartland | 26/06/2015 19:33:19 |

2929 forum posts 41 photos | What you have there is a Morticing machine for wood. Most likely it will have '0' taper in the spindle. It would need to run at high revs. Clive |

| JasonB | 26/06/2015 19:37:36 |

25215 forum posts 3105 photos 1 articles | Similar to the action of a slot morticer Clive but lacking the second lever to advance the work into the tool, looks like there is only one axis of quick movement. Also teh position of teh lever would limit you to quite short lengths of wood.

J |

| Michael Gilligan | 26/06/2015 20:17:01 |

23121 forum posts 1360 photos | Useful pictures, of lathes, Jason ... and I accept the family resemblance. However: Rainbows' description includes an adjustable spindle height [presumably effected by the knurled and pocketed drum, acting on eccentrically mounted bearings] How would this be used on a lathe ? MichaelG. . P.S. [Rainbows] ... some dimensions would be useful, if you have them. |

| Rainbows | 26/06/2015 20:54:25 |

| 658 forum posts 236 photos | "It's 9" high, and 13" deep. The bed is 3" x 7.5" with about 2.5" travel. The bed is moved across by the lever for speed."

I asked if they knew what the collet standard was. If it was a standard size and not some long defunct proprietry I might be tempted. Not sure why but tempted none the less. (It is for a lower price than an adept lathe so the temptation is real)

|

| John Stevenson | 26/06/2015 21:00:16 |

5068 forum posts 3 photos | Posted by Rainbows on 26/06/2015 20:54:25:

(It is for a lower price than an adept lathe so the temptation is real)

.

So at £3 I might be tempted |

| Andrew Johnston | 26/06/2015 21:13:32 |

7061 forum posts 719 photos | The lever between the pulleys and headstock looks exactly like the quick action collet closer on one of my Pultra lathes. I can't see why you'd need that on a mill, so my money is with the suggestion by JasonB, it's a second op lathe. If there is a height adjustment, it's not immediately obvious. If one is very lucky it may use one of the commoner watch making collets but is probably more likely to be proprietary. Unless one has a specific use for it, value is probably scrap only, and that's from a sufferer of OIS! Andrew |

| Enough! | 26/06/2015 21:40:11 |

| 1719 forum posts 1 photos | Posted by Rainbows on 26/06/2015 20:54:25:

Not sure why but tempted none the less.

Probably not so much for what it is but for what it could become. Might be a basis for a nice little tool grinder for instance. |

| Michael Gilligan | 26/06/2015 22:13:07 |

23121 forum posts 1360 photos | Posted by Rainbows on 26/06/2015 20:54:25:

"It's 9" high, and 13" deep. The bed is 3" x 7.5" with about 2.5" travel. The bed is moved across by the lever for speed." . Thanks for that. It is whatever it is, and could become one or more of many things !! MichaelG. |

| Michael Gilligan | 26/06/2015 22:55:14 |

23121 forum posts 1360 photos | Andrew, and Jason, There is a graduated scale just behind the knurled drum; but I can't see the units. My first assumption was that it related to angular displacement of an eccentrically mounted spindle ... but perhaps it measures linear displacement [if the spindle body is suitably threaded] ... Do you have any suggestions ? I also note that there is a maker's name [?] cast into the body, but I can't read it. ... When Rainbows buys it; all should be made clear. ... MichaelG. |

| Andrew Johnston | 26/06/2015 23:21:30 |

7061 forum posts 719 photos | On my repetition lathe the amount of closure of the collet is adjusted using a knurled ring with radial holes before it is locked in place prior to use, a bit like the one here. I can't see why it would need a scale though. It would also be strange if the unit was using dead length collets. Andrew |

| John Stevenson | 27/06/2015 06:56:46 |

5068 forum posts 3 photos | Read my post 6th one down.

It's not a lathe.

It's not a morticing machine.

It's a one op milling machine that only needs one axis of feed. They were used for putting slots in screws, putting hexagons on screw with two ganged cutters. The work was in jigs on the bed and the cutters went into the spindle. The spindle is on eccentrics to set the depth of the cutter instead of altering the jigs all the while.

I'm surprised that no one has found a picture of one from one of the old books.

|

| Michael Gilligan | 27/06/2015 07:04:01 |

23121 forum posts 1360 photos | Thanks for the confirmation, John MichaelG. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in