Best method of boring a bearing housing

| Jon Gibbs | 18/05/2015 16:08:26 |

| 750 forum posts | I have ordered some 15x35x11.8 taper roller bearings to make one of these things...

based around a length of 45mm square bar but I have realized that, while I know how to cut the bearing housings on the boring bar holder, I will need to cut four housings in the ends of a 200mm 45mm square bar on my old Myford ML7. I'm not bothering with the intermediate holes. What's the best way of doing this? I currently don't have a boring head - do I need one or is there a cheap and cheerful way of managing without? Any guidance gratefully received Many thanks Jon |

| Bob Rodgerson | 18/05/2015 16:24:34 |

| 612 forum posts 174 photos | The Cheapest way would be to mount the job on the cross slide at centre height, centre drill and drill progressively larger until the correct size drill goes throughout the bar. Move the bar along using the cross slide hand wheel divisions to give you the correct centre distance then start again with the above method. Repeat for however many holes you need. |

| Jon Gibbs | 18/05/2015 16:52:33 |

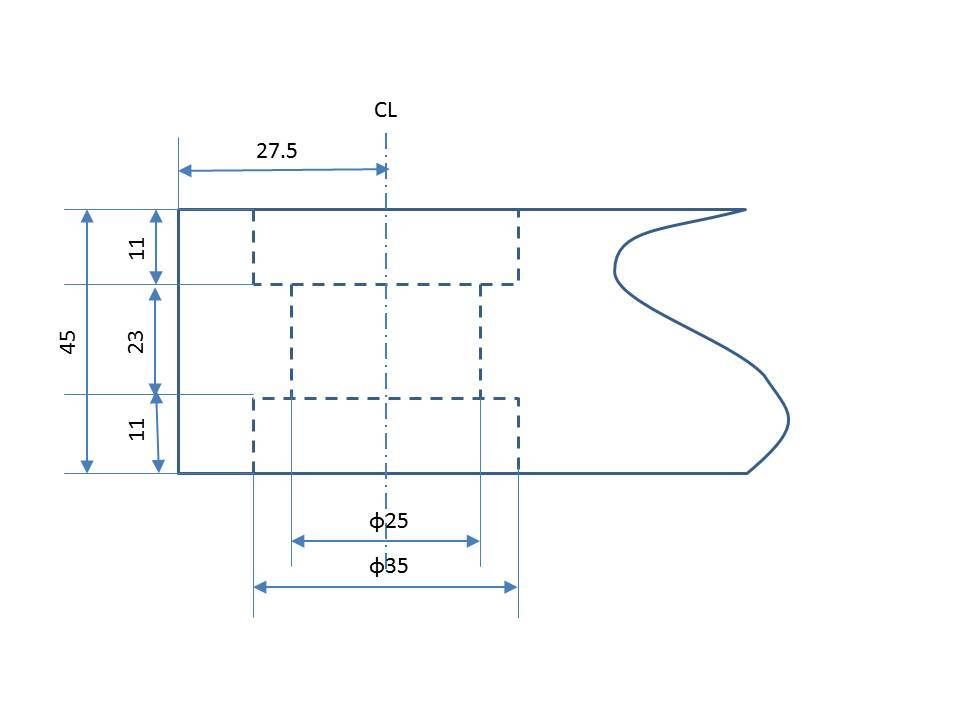

| 750 forum posts | Hi Bob, Thanks for the suggestion. I think I should have been a bit more specific. I think that I need the bearings to sit firmly in the bar with the ends bored like this...

I think that to maintain alignment, the 35mm holes need to be a snug fit for the bearing shells when they're bored and when the bearings are installed they sit slightly proud of the bar. Unless anyone has a better idea? Many thanks Jon Edited By Jon Gibbs on 18/05/2015 16:53:55 |

| JasonB | 18/05/2015 16:57:41 |

25215 forum posts 3105 photos 1 articles | Packed up and clamped the sq bar crossslide and use a between ctrs boring bar, once you have it set right for the bearing just swap it end for end. It would be easier if the 25mm hole could be larger and I can't see why not as you just need a shallow register for the bearing outer race.

Edited By JasonB on 18/05/2015 16:59:46 |

| Jon Gibbs | 18/05/2015 17:18:14 |

| 750 forum posts | Thanks very much Jason. The 25mm was just a rough guess to highlight the need for the shells to rest on something and could obviously be quite a bit bigger as you say. Many thanks again Jon |

| Bob Rodgerson | 18/05/2015 17:56:59 |

| 612 forum posts 174 photos | Hi Jon, I got the wrtong end of the stick with this one, I thought they were just through holes. Jasons suggestion is a good one, it is a bit of a pain setting the cutter to the right diameter but once set, as Jason says it could be turned around and the other end set to machine a slightly smaller bore for the bearing to register against. Bob |

| JasonB | 18/05/2015 18:21:20 |

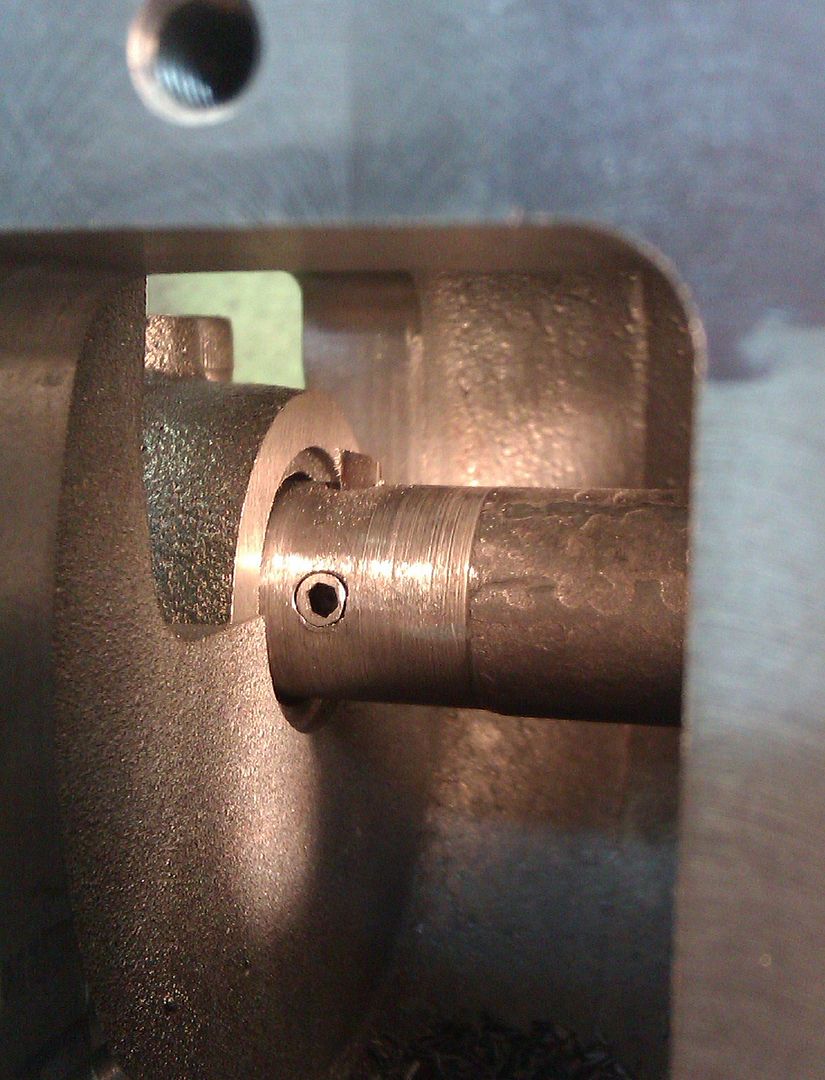

25215 forum posts 3105 photos 1 articles | My thought was to bore them all out to say 32mm all the way through, then set up again and adjust the bar to cut the 35mm hole for one bearing, turn end for end and go straight in with a single 1.5mm cut for the opposite side. Then set the next bar end up and repeat. Or if you don't feel you can reset the parts true make a second bar, one for teh through hole and another for the bearing. They are easy enough to make, the one in the photo was just an old 3/4" bolt |

| Les Jones 1 | 18/05/2015 18:30:10 |

| 2292 forum posts 159 photos | Hi Jason, Les. |

| Jon Gibbs | 18/05/2015 19:02:48 |

| 750 forum posts | Hi Jason, Thanks very much. When you say " turn end for end and go straight in with a single 1.5mm cut for the opposite side" am I turning the boring bar end for end? Les, my lathe does have reverse thanks. Jon |

| John Stevenson | 18/05/2015 19:20:31 |

5068 forum posts 3 photos | Make them out of round bar stock on the lathe then weld then onto a 45mm square box section.

Simples. |

| JasonB | 18/05/2015 19:31:03 |

25215 forum posts 3105 photos 1 articles | Yes turn the boring bar end for end, that way the two bearing holes will be exactly in line. |

| frank brown | 18/05/2015 19:43:48 |

| 436 forum posts 5 photos | Through bore the bearing fitting diameter and fit a spacer with a bit of epoxy to keep them apart. Frank |

| Nigel McBurney 1 | 18/05/2015 20:09:36 |

1101 forum posts 3 photos | Welding a round housing to a square bar is ok for a garden trolley,a round housing sufficiently accurate to accept bearings will distort and or shrink when welded ,as suggested above bore through and fit a central spacer,I would secure it with high strength loctite and a pin for added security.Boring housings from each side,which are inline ,takes a lot of skill to get right. |

| Jon Gibbs | 19/05/2015 08:36:19 |

| 750 forum posts | Thanks very much to everyone - I really appreciate all of the replies. I just realized that although my lathe will go in reverse the catch-plate for the boring bar will be wanting to unscrew from the nose in reverse which makes Frank and Nigel's suggestions perhaps the best for me. At least I feel that it's within my limited capabilities - My welding is certainly not up to John S's suggestion, although I can see that it would work. Is there a way to get around the catch-plate unscrewing? The chucks on my woodlathe achieve this with set-screws onto the spindle nose which is ok for wood tolerances but clearly a no-no. Jon |

| MalcB | 19/05/2015 09:11:42 |

| 257 forum posts 35 photos |

Without wanting to do any mods to your lathe spindle nose then you will need to do some thinking away from the box.

There is always the easy option of using a driving centre but they are quite rare to find, not seen one being sold for a while now. You may want to consider making one.

I would make a soft morse taper centre for your spindle taper with a parallel portion sufficient to grub screw a collared catch plate onto ( or Welded ). Before turning the tapers on the centre, drill and tap the morse end for a suitable drawbar and make one to suit. A lot of work for a per chance occasion of use but it's an option. I have a couple of combined self contained catch plates with parallel shanks that can be held in a collet, but you do need a collet set up for your lathe for to use these.

Edited By Malc Broadbent on 19/05/2015 09:16:20 |

| Bob Unitt 1 | 19/05/2015 09:34:53 |

323 forum posts 35 photos | Probably a bodge, but what I'd do : Bore through at 35, make up a press-fit spacer 35 OD, 25 ID, 23 long, press in (and secure with a grubscrew from the side if necessary). eta: Sorry Frank, only just noticed you'd already suggested this. Edited By Bob Unitt 1 on 19/05/2015 09:36:09 |

| Jon Gibbs | 19/05/2015 09:54:38 |

| 750 forum posts | Hi Malc, Brilliant! - thank you. I think a few quid on an M10 threaded blank end arbor machined to a 60 degree point would be just as good - perhaps even with a short length of rod poking out to catch the drive dog? I have an ER32 collet chuck but it also screws onto the spindle nose Bob, no problem. Thanks again folks Jon

Edited By Jon Gibbs on 19/05/2015 09:57:52 |

| Neil Wyatt | 19/05/2015 10:24:29 |

19226 forum posts 749 photos 86 articles | Or turn a point on a bit of scrap bar held in the 3-jaw, you can use one of the jaws to engage with a suitably shaped drive dog. Neil |

| JasonB | 19/05/2015 10:43:20 |

25215 forum posts 3105 photos 1 articles | And watch as the chuck unscrews as I would think it fits in the same way as the catch plate and ER32 chuck!

Though thinking about it as the pressure from the ctr will be against the chuck jaws it would not really be able to unscrew without appling a lot more pressure and the bar won't compress Edited By JasonB on 19/05/2015 10:47:28 |

| Jon Gibbs | 19/05/2015 11:09:00 |

| 750 forum posts | Thanks Jason. I went through the same thought process when I read Neil's suggestion I suppose that also means that the collet chuck might also be ok in practice ...especially if the bar in both cases has a shoulder that means it can't be forced back into the jaws. Jon |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in