KX1 CNC Mill Clearance Offer

| JasonB | 02/03/2019 16:35:22 |

25215 forum posts 3105 photos 1 articles | There is only so much foam you can cut before the lure of metal becomes to much so I mounted up one the 80mm vice on loan from ARC rather than risk my own The two through holes were done with a 6mm FC3 cutter, 2500rpm, 150mm/min and I set it to work out its own depths in 5 passes. Finish seems nice and crisp with no indication of the hole being formed in 5 passes and a quick measure of the the square hole gives 19.99 x 19.98mm for the 20mm on the drawing which I'm reasonably happy with considering the mill is still just sat on the pallet and I have not looked at the gibs or tram. |

| blowlamp | 02/03/2019 19:05:52 |

1885 forum posts 111 photos | Posted by JasonB on 02/03/2019 16:35:22:

There is only so much foam you can cut before the lure of metal becomes to much so I mounted up one the 80mm vice on loan from ARC rather than risk my own The two through holes were done with a 6mm FC3 cutter, 2500rpm, 150mm/min and I set it to work out its own depths in 5 passes. Finish seems nice and crisp with no indication of the hole being formed in 5 passes and a quick measure of the the square hole gives 19.99 x 19.98mm for the 20mm on the drawing which I'm reasonably happy with considering the mill is still just sat on the pallet and I have not looked at the gibs or tram.

Some up & down in the Z is inevitable due to the way many CAM systems offset toolpaths from the geometry and commence cutting at the centre of each generated region. If you feel there's too much dancing going on, then CamBam might be a bit better and has a very generous trial period that you could explore and probably has the greatest capability for the money (if you don't fancy going the Fusion 360 route). If you can squeeze some more speed from your rapids (Z axis in the main), it's surpirising how much of a difference it can make in overall job time.

Martin. |

| John Haine | 02/03/2019 19:41:25 |

| 5563 forum posts 322 photos | Yes, Z feeds can take a lot of time - I just ran a job today, G-code generated in G Simple, where I edited the code afterwards to remove the over generous clearances etc and halved the run time. 150 mm / min is more my kind of feed - today's job was CZ120 brass with an FC3 cutter at 5000 rpm and 200 mm/min. This time I experimented with blue tape/superglue to hold the material down - see Worked well. |

| blowlamp | 03/03/2019 13:32:46 |

1885 forum posts 111 photos | Some Mach3 gcode of Jason's Star & Square pocket. I estimated the overall size @ 25mm x 55mm. Feedrates & spindle speed are modest with just one pass at 1mm cutting depth (to keep gcode size down), using a 3mm diameter cutter.

Cont >>> |

| blowlamp | 03/03/2019 13:33:37 |

1885 forum posts 111 photos | Cont >>>

G1 X-8.4991 Y11.4895 Z-0.4588 |

| JasonB | 03/03/2019 17:14:49 |

25215 forum posts 3105 photos 1 articles | Thanks for that I'll see how it compares. For anyone interested I have put the code for that group of 4 shapes on dropbox. Depths did vary from 1-3mm but you got the size about right. I was not going to touch the KX3 today but a comment was made on another forum that CNC was like 3D printing with both taking a "hours and hours" to print or machine something. I had mentioned before that the engine I'm just completing had some parts that would have suited CNC machining, these two legs being a good example with the Rotary table work taking me about 5 hours to complete.

I already had them modelled in Alibre so it was just a case of exporting a DXF file and opening that in Cut2D, after a bit of a learning curve as there were a few things I had not done before in Cut2D I had the code after about 10mins. It said that I could cut the part in 8mins 23secs so allowing a second op to form the web on the opposite side 10mins each by CNC. This is a test one in UPVC which took the 8 and a bit mins, the UPVC is thicker than the metal so it has not cut right through.

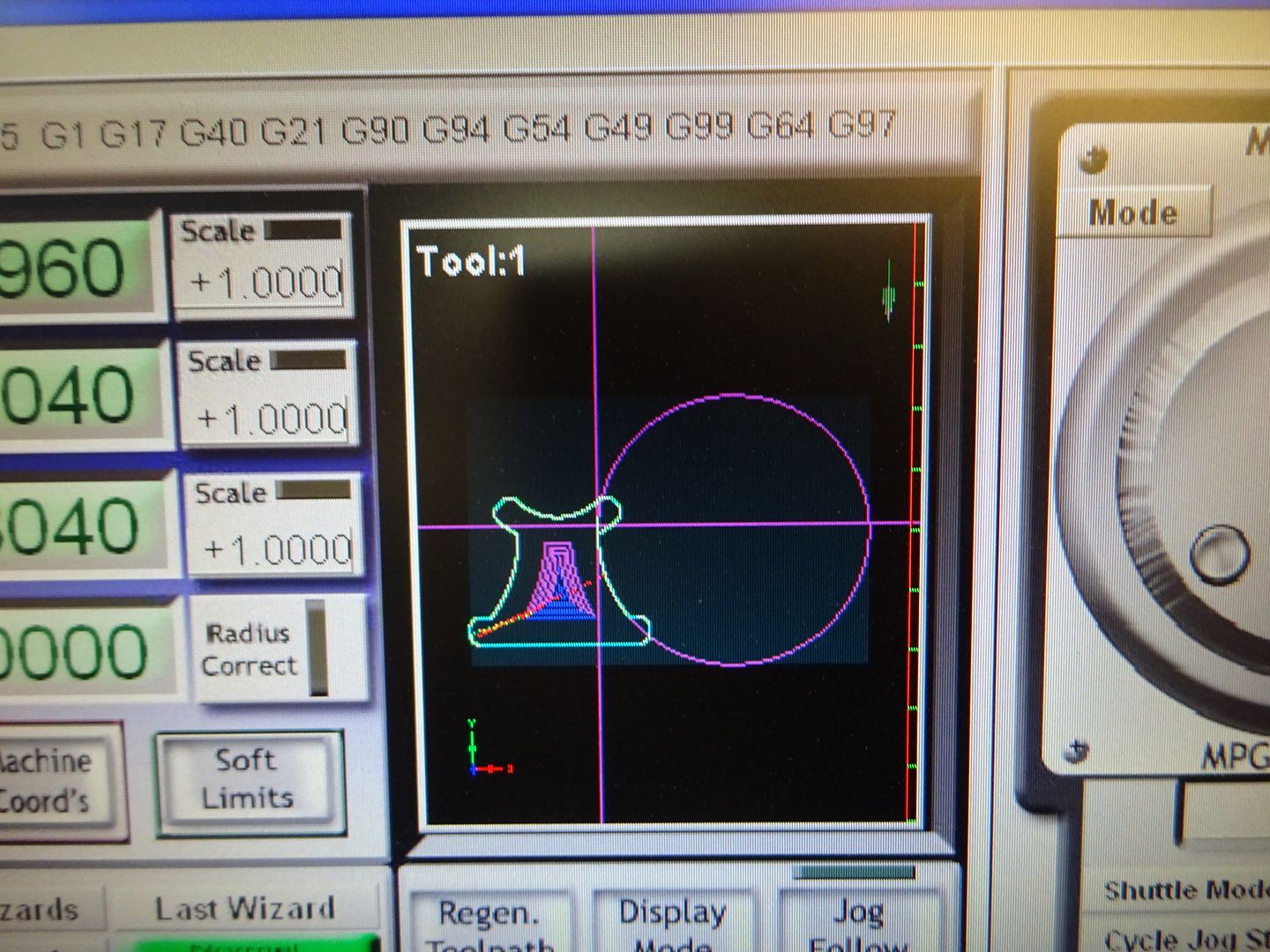

I decided to play safe and before cutting metal reduced the DOC but speeded up the spindle which added about 3mins more to the code. When I loaded the code into Mach3 I noticed an extra path on the screen (pink circle) and should have stopped and sorted it there and then but carried on with my finger over the stop button.

With about 30secs left to run the mill started to move in the wrong direction and luckily I stopped it before too much damage was done, just a nick out of the part.

I redid the code and ran it again and all came out OK in just under 12mins, only downside was I used a bit of scrap with a hole in it.

If I wanted to finish the job then it would just be a case of flipping it over and running the first pocket code again then cutting away the tabs. I did not video it all but this is 3 clips stitched together showing one pass of each of the 3 ops that form the code.

|

| Ron Laden | 03/03/2019 17:31:14 |

2320 forum posts 452 photos | Great stuff Jason, not only will it save you time but saves all that manual work and all the setting up. Have you cured the problems the mill had in the Z, looks as if you have. Ron |

| Andrew Johnston | 03/03/2019 18:58:53 |

7061 forum posts 719 photos | Posted by JasonB on 03/03/2019 17:14:49:

When I loaded the code into Mach3 I noticed an extra path on the screen (pink circle) and should have stopped and sorted it there and then but carried on with my finger over the stop button. Been there, done that and got the misplaced cuts to prove it. That's why I started using a backplotter program (NcPlot) that plots a toolpath from the G-code. It also gives more accurate time estimates than the CAM program, and lists the extents of travel in all axes, which is a useful sanity check. Andrew |

| JasonB | 03/03/2019 19:07:24 |

25215 forum posts 3105 photos 1 articles | Ron, head seems to be behaving itself now.

Thanks, Andrew, It may be something I will have to look into. The Cut2D did not show any odd paths but at least it all seemed to move in a logical way on this part. Screen capture of the Cut2D simulation for anyone interested.

|

| John Haine | 03/03/2019 22:23:47 |

| 5563 forum posts 322 photos | Well now we have two moderators getting into CNC maybe we can get the ability to upload other file types to the site so we can share g code? |

| duncan webster | 15/03/2019 16:46:25 |

| 5307 forum posts 83 photos | You happy men with your new milling machines will be in want of a stand for it, see ad I've just placed in classifieds |

| Ian Johnson 1 | 15/03/2019 17:11:22 |

| 381 forum posts 102 photos | Nice work Jason those legs are the ideal job for a CNC milling machine. Ian |

| martin perman | 15/03/2019 18:53:13 |

2095 forum posts 75 photos | Posted by John Haine on 03/03/2019 22:23:47:

Well now we have two moderators getting into CNC maybe we can get the ability to upload other file types to the site so we can share g code? Although interesting it would be a shame if the forum and magazine became more CNC orientated instead of day to day model engineering. Martin P |

| Ian Johnson 1 | 18/03/2019 00:45:32 |

| 381 forum posts 102 photos | Just a few rambling thoughts on Martin's comments above. I think that CNC is an extension of the model engineers tool box. Model engineering has embraced technology from industry for decades, such as power feeds, digital read outs, digital micrometers and calipers, LED lamps, laser cutting, plasma, 3D printing etc. What industry does today, model engineers do tomorrow. I can even see EDM becoming more affordable in the hobby scene very soon. But there will always be a very large participation in manual machining because of the skill and satisfaction it brings. I think CNC has been a breath of fresh air for our hobby, otherwise it could go the same way as the classic motorbike scene, I occasionally buy Classic Bike magazine and read the same stuff I read thirty years ago! I think I've rambled enough Ian |

| Neil Wyatt | 18/03/2019 18:58:50 |

19226 forum posts 749 photos 86 articles | Posted by duncan webster on 15/03/2019 16:46:25:

You happy men with your new milling machines will be in want of a stand for it, see ad I've just placed in classifieds My X1 came with a fully enclosed cabinet made by John Stevenson out of recycled Tiger Tank... Neil |

| Neil Wyatt | 18/03/2019 19:01:08 |

19226 forum posts 749 photos 86 articles | Posted by martin perman on 15/03/2019 18:53:13:

Posted by John Haine on 03/03/2019 22:23:47:

Well now we have two moderators getting into CNC maybe we can get the ability to upload other file types to the site so we can share g code? Although interesting it would be a shame if the forum and magazine became more CNC orientated instead of day to day model engineering. Martin P There's more than enough room for everything on the forum, extra CNC doiesn't reduce the space for other topics. As for the magazines, they follow the interests of the readers and the authors - I am always surprised that we get relatively little CNC oriented content. Neil |

| Neil Wyatt | 18/03/2019 19:02:08 |

19226 forum posts 749 photos 86 articles | Posted by John Haine on 03/03/2019 22:23:47:

Well now we have two moderators getting into CNC maybe we can get the ability to upload other file types to the site so we can share g code? We can host files in .ZIP format, but they have to go via a moderator. Neil |

| Andrew Johnston | 18/03/2019 19:19:47 |

7061 forum posts 719 photos | Posted by Neil Wyatt on 18/03/2019 19:01:08:

As for the magazines, they follow the interests of the readers and the authors - I am always surprised that we get relatively little CNC oriented content. I have had articles published that include CNC machining. But given the current requirements for shortish articles, especially for beginners, I'd rather assumed that CNC was off the table? Andrew Edited By Andrew Johnston on 18/03/2019 19:20:16 |

| Neil Wyatt | 18/03/2019 20:09:03 |

19226 forum posts 749 photos 86 articles | Why should CNC article be any longer than non-CNC? I though CNC was supposed to make things quicker Seriously, CNC articles don't need to be a series - Joe Noci's shaper was a good example, although I did want it to have another page or two, so we gave it the cover instead. There have been others, but not as many as I would have expected. Now things have settled I go up to 3 or 4 parts for articles, if they are sufficient to sustain interest. I won't consider a longer series until the lathework and milling for beginners are finished, but these have been alternate issues to keep up the variety. Alibre would have been the same, except we had to align it with the 6-month trial period. A CNC for beginners series would have to be generic, but any g-code or other examples would be uploaded, not in the magazine, like the examples for the Alibre tutorials. Perhaps 6 or 7 articles every other issue for a year? Neil Edited By Neil Wyatt on 18/03/2019 20:09:36 |

| Ian Hewson | 18/03/2019 20:23:27 |

| 354 forum posts 33 photos | More cnc wouldn’t tempt me back to MEW, that was one of the reasons I cancelled my subscription in the first place. Long lines of g code as Blowlamps above leave me cold. Each to there own though. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in