Has anybody built the flame eater "Nick"?

This is another pre-milled kit from Bengs

| Michael Gilligan | 30/05/2016 12:03:59 |

23121 forum posts 1360 photos | Posted by Brian John on 30/05/2016 10:21:36:

... The cuts did not meet so I evened things up with the bench grinder ... . Brian,

MichaelG. |

| JasonB | 30/05/2016 12:23:11 |

25215 forum posts 3105 photos 1 articles | You could look into getting a small flycutter for the lathe Lathe Brian as that would have done the job.

As Michael says brass will clog the grit on your bench grinder. The countersink is 45Degrees either side so the included angle is 90 |

| Ian S C | 30/05/2016 12:33:12 |

7468 forum posts 230 photos | Grinding brass clogs up the wheel face, and later grinding will tend to make the wheel heat up, this can in extreme cases cause the wheel to crack. the wheel needs dressing to clear the brass, there is probably not much there. Just another degree on the learning curve. Keeping a few files for brass only work is a good idea, for small jobs filing is often quicker than setting up and machining. Ian S C |

| Brian John | 30/05/2016 12:44:15 |

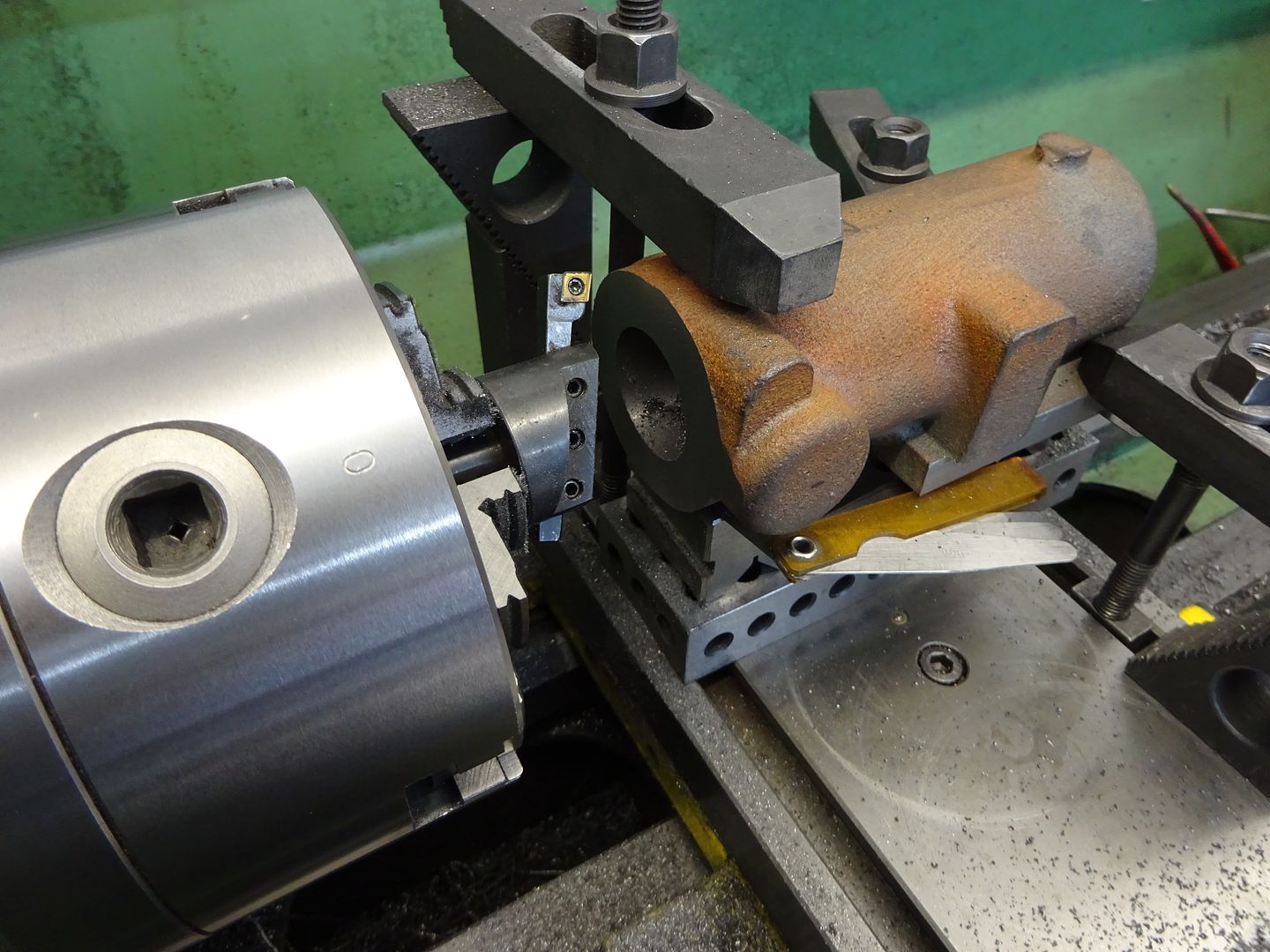

| 1487 forum posts 582 photos | Okay, I will give the bench grinder a miss next time I do something like this. I will go straight to the vice and the file. Flycutter : what is being used to hold the work piece in that photo and. what would I use to hold the work piece on my lathe ? |

| JasonB | 30/05/2016 12:48:04 |

25215 forum posts 3105 photos 1 articles | You can use the same method that you used when sawing. But it would be better if your topslide could be removed and the work held to that but not sure if yours can? |

| Brian John | 30/05/2016 12:56:04 |

| 1487 forum posts 582 photos | Yes, the top slide can be removed. I always remove that when cutting threads using a die wrench as the top slide gets in the way. There are numerous types of dressing tools to dress a grinding wheel. Is any one type better than the others ? Edited By Brian John on 30/05/2016 12:57:03 |

| Brian John | 31/05/2016 10:02:38 |

| 1487 forum posts 582 photos | I have finished drilling and tapping the cylinder head and it can be seen with the chimney attached in photo 1. I did some more soft soldering today ; the 188 degree solder seems to flow more readily than the 243 degree solder so I am using that. The eccentric and its bushing did not give any problems but the crankshaft did as I suspected it would. The problem is getting enough flux in the right place. You have to flux before you put the parts together and moving the crank plates along the crank shaft removes most of the flux. I decided to drill and tap the crank plates for M2x3mm grub screws to hold everything in place before soldering. I can file the grub screws off later if they have been soldered into position. I got the job done but it does not look very neat ; I could not get the solder to flow properly because of the lack of flux. Removing the grub screws shows that enough solder got through but I am not happy with the result. How should I have done this ? Another way would be to not use solder at all and just drill and tap right though to the crank (M3X4mm grub screw) then Loctite everything into position. I might order these parts again and give that a go at a later date. NOTE : that is my new hand held burner for soft soldering. Edited By Brian John on 31/05/2016 10:03:25 Edited By Brian John on 31/05/2016 10:05:04 Edited By Brian John on 31/05/2016 10:22:20 |

| Ian S C | 31/05/2016 16:16:21 |

7468 forum posts 230 photos | To dress the wheels on my grinder I use a star dressing wheel, you may know these things, a steel/cast iron handle, with alternately placed plain and star shaped washers that are run against the rotating grinder wheel, also useful if you manage to wear a groove in the face of the grinder wheel. There are other types of dressers usually with one or more diamonds in the end, they aren't that expensive, but although you don't need one often, you really do need some way to dress the grinder. The crankshaft could be assembled with shaft lock Loctite, I'v done that on my smallest motor with 3 mm diameter shaft and crankpin and the crank cheeks are about 2 mm thick, it hasn't fallen apart ------yet. Ian S C Sorry I thought the crankshaft was more visable

|

| Brian John | 31/05/2016 17:36:57 |

| 1487 forum posts 582 photos | I have ordered a diamond tip dresser ; that will do for a start. I have a bigger problem now : I have carefully drilled and tapped all 12 holes in the aluminium base plate only to discover that the socket caps will barely engage the threads...how frustrating. Some weeks ago I switched from using 1.6mm to 1.7mm tap drills for 2 X 0.4mm threads after experiencing two broken taps. This has worked well for brass but I think aluminium requires 1.6mm. I will have to drill and tap it all again. Edited By Brian John on 31/05/2016 17:37:44 Edited By Brian John on 31/05/2016 17:40:38 |

| Brian John | 01/06/2016 12:08:13 |

| 1487 forum posts 582 photos | I was going to make a start on the cylinder today but there is still one confusing part in the instructions : ''An M2 screw must be adjusted to fit the top M2 bore hole on the cylinder bracket side.'' I assume they are referring to the M2 screw which passes through the lubricator hole. Note that six holes must be drilled and tapped on the LH side of the cylinder in the diagram below. What do they mean by ''adjusted'' ? I am thinking of rotating the cylinder 30 degrees so that no screws pass through the lubricator hole. But this would leave the lubricator tilted at 30 degrees to the vertical and it might look a bit funny.

Edited By Brian John on 01/06/2016 12:09:44 Edited By Brian John on 01/06/2016 12:10:27 Edited By Brian John on 01/06/2016 12:12:38 |

| JasonB | 01/06/2016 12:16:49 |

25215 forum posts 3105 photos 1 articles | Adjusted may mean shortened so it only goes in a little way and does not hit the M3 thread on the bottom of the lubricator |

| Brian John | 01/06/2016 12:53:41 |

| 1487 forum posts 582 photos | That would mean it only goes in 0.75mm. It is hardly doing much at that length is it ? What about my idea of rotating the cylinder 30 degrees. NOTE : it specifically mentions not using any oil on the piston so I wonder if a lubricator is necessary at all. I could also skip out that first cooling fin and move the lubricator further along. That would give an extra 1.75mm of thread. But probably best to leave that option for now.

Edited By Brian John on 01/06/2016 12:57:56 Edited By Brian John on 01/06/2016 12:58:09 Edited By Brian John on 01/06/2016 13:03:41 |

| the artfull-codger | 01/06/2016 14:17:47 |

304 forum posts 28 photos | Brian, I used to dress my wheels with a diamond dresser [we used them all the time in the decorative glass trade] dressing all the processing wheels, but now all I do is buy a cheap diamond angle grinder wheel [sometimes for a quid at autojumbles & steam rallys] & offer it horizontally to the grinder & it cleans it up a treat, & it's so cheap. Graham. |

| roy entwistle | 01/06/2016 18:03:06 |

| 1716 forum posts | Brian Stick to the drawing |

| Brian John | 02/06/2016 10:06:30 |

| 1487 forum posts 582 photos | Roy : yes, I will. The soldering on my crank has not held and it all came apart. I am not sure what went wrong here. I can soft solder brass to brass or copper without any problem but brass to silver steel is not working for me. I will have to start again from scratch. I attempted to make a new base plate and after VERY carefully measuring and marking it out, I proceeded to drill with a 1.6mm drill bit. The drill bit snapped off in one of the holes (top LH in photo). I then tried to dissolve the drill bit by placing the work piece in an Alum solution. I put it in a Pyrex bowl which I was heating on a portable gas stove when the Pyrex dish exploded ! I was lucky I was not injured as this thing went off with a bang. I thought you could heat Pyrex directly with a naked flame but obviously I was wrong. Didn't we heat up chemical solutions at school in Pyrex beakers over a Bunsen burner ? Or was there an asbestos pad in there somewhere...I cannot remember ? All in all, a very bad day. Next time I drill with a small drill bit I will use a drop of tap magic in each marked dimple. I just hope I can save this work piece somehow. I am not in the mood to make a third one. UPDATE : I now know that there is Pyrex used in laboratories and there is Pyrex used in kitchenware. They are NOT the same product. Today was a lesson in what NOT to do ! Edited By Brian John on 02/06/2016 10:07:36 Edited By Brian John on 02/06/2016 10:08:08 Edited By Brian John on 02/06/2016 10:11:43 Edited By Brian John on 02/06/2016 10:40:17 |

| JasonB | 02/06/2016 10:25:36 |

25215 forum posts 3105 photos 1 articles | Brian have you seen this build of Nick? |

| Brian John | 02/06/2016 12:30:38 |

| 1487 forum posts 582 photos | Thanks Jason, that will be useful. I notice that he machined the flywheels by holding them in the chuck by the inner rims. I might give that another go. I was getting nowhere with the face plate. I have worked out how I will do the crankshaft : rather than cutting the short shank exactly 16mm and trying to solder that in position, I will cut it oversize (26mm) so that I can solder from the outside then cut of the excess later. I will give the Alum another go on the aluminium base plate but I will let it soak at room temperature in a glass jar ; it will probably take a week or so to disolve the broken drill bit...maybe even longer. Edited By Brian John on 02/06/2016 12:32:39 |

| Ian S C | 02/06/2016 12:57:49 |

7468 forum posts 230 photos | I would have though that by solder for the crankshaft, it would actually mean silver solder, ordinary low temperature solder/plumbers, electrical solder is not much use for any joint that has any stress. You would get a stronger joint using shaft lock adhesive. Ian S C |

| Brian John | 02/06/2016 13:18:51 |

| 1487 forum posts 582 photos | In the instructions they actually warn against using silver solder : '' Do not hard-solder the crankshaft !!! Distortion !!! " I was surprised as I did not think silver solder would be a problem. I am going to use high temperature (243 degree) soft solder this time. I am still toying with the idea of drilling right through the crank plates and the shafts by drilling and tapping for M3 grub screws and holding everything in position that way. Edited By Brian John on 02/06/2016 13:19:24 Edited By Brian John on 02/06/2016 13:24:12 |

| Brian John | 03/06/2016 09:54:32 |

| 1487 forum posts 582 photos | I had another go at the crankshaft today using lots of 243 solder...probably too much. But everything held together this time. I think I let the flame linger a few seconds too long ; I should have removed the heat as soon as I had a nice fillet of solder around the joins. I am still getting used to my small burner which I use for soft soldering. It produces more heat than I expected. I put some flux on the inside of the holes on the crank plates before sliding them onto the shanks hoping that some of the flux would stay inside and not get removed in the process. I put most of the flux on after everything was placed in position : lots of flux on the outside of the crank plates for the short shank and lots of flux on the inside of the crank plates for the long shank as these are the parts to be removed later. I tested it in the lathe and it runs true...all good. NOTE : if anybody is looking for Alum powder for removing broken taps and drill bits then ask at your nearest Indian grocery store (fatakdi powder). Edited By Brian John on 03/06/2016 09:54:55 Edited By Brian John on 03/06/2016 09:56:40 Edited By Brian John on 03/06/2016 09:57:30 Edited By Brian John on 03/06/2016 09:58:31 Edited By Brian John on 03/06/2016 09:59:13 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in