2 inch face mill problems

2 inch face mill problems

| JasonB | 10/05/2018 07:03:27 |

25215 forum posts 3105 photos 1 articles | Both from Cutwel as they sell individuals, did not want a box if things were not going to work. Funny enough Murray that is the exact insert that I ordered but got the ones shown in my photo. Now you have confirmed they should look like that and it was not a generic photo I may e-mail them to check. looks a lot mor elike this one from APT Edited By JasonB on 10/05/2018 07:49:42 |

| HasBean | 10/05/2018 09:28:55 |

| 141 forum posts 32 photos | Jason, Those ones in the picture from APT are identical to the ones I have for aluminium. Paul |

| Muzzer | 10/05/2018 10:06:03 |

2904 forum posts 448 photos | I haven't ever bought Korloy APKT H01 - only Mitsubishi from what I can see. However, looking at the Korloy milling insert catalogue (page 5), it seems the APKT comes in a whole range of weird and wonderful chipbreakers and materials. Yours is the "APKT MA" version, it seems. At least it seems to work well... There's a whole world of inserts out there that leave most of us lost! We have only scratched the surface. Murray |

| JasonB | 10/05/2018 11:24:13 |

25215 forum posts 3105 photos 1 articles | Just heard back from Cutwel and it seems the image on the website is wrong, they will change it to the correct image which from Murray's link is the MA but the photo shows probably the MA2 or MA3. As Muzzer says it is the letters after the basic shape, size and corner radius that can make all the difference and often not shown from the cheaper suppliers and seldom mentioned when someone says a certain tip works for them. Not helped by the fact these letters and numbers are manufacturer specific rather than standard across the lot. On our hobby machines the finer differences will not really come into it but a "sharp" cutter can make all the difference as these few videos have hopefully shown, bit like using a**GT insert on a light weight lathe that would otherwise not take well to the use of carbide. Infact there is a whole world of everything out there, I got a 2" high pile of cataloges with the order and that was just measuring, milling and machine accessories. |

| richardandtracy | 10/05/2018 19:55:42 |

943 forum posts 10 photos | In conclusion, then, it's highly probable that, if other causes have been eliminated and the finish from these Bang good style cutters is still inadequate, then different inserts should be investigated before condemning the cutter as rubbish. That is good to hear, but doesn't help those who've found the taper on the mandrel to be wrong. What has surprised me,though, is their sensitivity to insert geometry. It is much more sensitive than lathe tools seem to be. Regards Richard.

|

| Martin Newbold | 13/05/2018 22:06:09 |

| 415 forum posts 240 photos | if its rocking. Is it rocking on the face you have cut beacuse steps of differant hieght in the cut face. Sometimes the mill may not be inserted and secured properly and may be dropping lock the vertical hieght on each pass if you have the option. check your fixing of the part your milling. Its easy to get swarf under it and or bolting is not holding t down flush with the mill bed. Have only used flueted mills not inserts and generlly if its a large area a bigger mill will git better than small one as it will not require so many steps. Finally how much are you cutting on each pass . M. |

| Martin Newbold | 13/05/2018 22:13:18 |

| 415 forum posts 240 photos | Cricky how much are you tring to cut. i would try half that and a smaller mill bit . I dont think your machine is big enough to support what you are doing. That looks like an inch bit and you are trying to cut complete inch in one pass.?

When I have been milling I use less than a 1/2 fluted mill on a big very heavy old friends machine that doesnt move when you cut . This smaller mills are not so solid,

Posted by JasonB on 06/05/2018 18:37:13: I bought one too and had the same poor result. You can see by the worklight how much vibration is caused. I think it is only cutting on one tooth and the whole cutter is riding up on the work.

|

| JasonB | 14/05/2018 06:58:47 |

25215 forum posts 3105 photos 1 articles | Martin, try reading the rest of the post, the mill easily coped when I used different inserts. Also read the title of the thread, it's a 50mm face cutter not a 1" bit Also half of which cut the 0.1mm DOC or the 1.0mm DOC? Edited By JasonB on 14/05/2018 07:30:25 |

| Martin Newbold | 14/05/2018 20:12:17 |

| 415 forum posts 240 photos | Jason thats a 1.9" dia cutter the vid you posted was using whole bit . As I said on my m8s rigid dinosur mill which is so solid it ways several tons I only use a 1/2 fluted mill tool on this using half the cutter. It doesnt need a dro as it doesnt flex. The video also showed no use of cutting fluid or oil or coolant / lubricant. If your DRO is not reading zero then your head is flexing and if its alternating then you are not cutting evenly . Some metals have had spots in them . This is worse in alloys . Just saying as I dont use inserts as they overheat without coolent and then distemper or blunt which happens for me. I have just installed coolent on lathe and am not sure i would still use inserts.

M |

| JasonB | 14/05/2018 20:33:13 |

25215 forum posts 3105 photos 1 articles | Martin, I'll say it once again Read the rest of the thread. -I know what size cutter I'm using it was you that said it looked like a 1" cutter. 50mm cutter on 45mm wide work is not using the full width of the cutter. -That is cast iron I'm cutting don't know of anyone who would suggest using cutting fluid on that. -DRO has nothing to do with flex but does come in handy to eliminate the need for compensating for backlash. Why not watch the other video I posted in the thread which you have obviously not done. CI first cut dry 45mm wide 1mm DOC, then steel with a little soluable oil 32mm wide 1mm DOC then aluminium with some paraffin 45mm wide 1mm DOC faster feed. All cutting well with no flexing as the tips were a better quality and geometry than the cheap Bangood ones. You will notice that the chips from the steel are coming off blue, the suds really is not doing anything and may as well not have been used, this shows the tip is working right. Your loose wobbly chuck is most likely what is damaging inserts as well as pussy footing about with them.

Edited By JasonB on 14/05/2018 20:35:55 |

| Jon | 18/05/2018 09:37:48 |

| 1001 forum posts 49 photos | Totally agree with Muzzer and Jason been there done it until tried APHT, though would want coated for steels. To give you some idea some years back we couldnt get the bearings out of a Skoda hub, think GEN2?. The only tools had to hand were those WHT APHT meant for aluminium plunged down broke through cage, hardened steel bearings (2), cage another row of cage, hardened steel bearing and cage. In saying that the tips were not happy opening out much softer hardened tool holders to accept larger tooling had to use the Seco MM16-16019-A30-E06 and you dont want to know the price.

|

| gary arthur | 09/09/2018 01:01:00 |

113 forum posts 706 photos | Posted by JasonB on 07/05/2018 07:08:35:

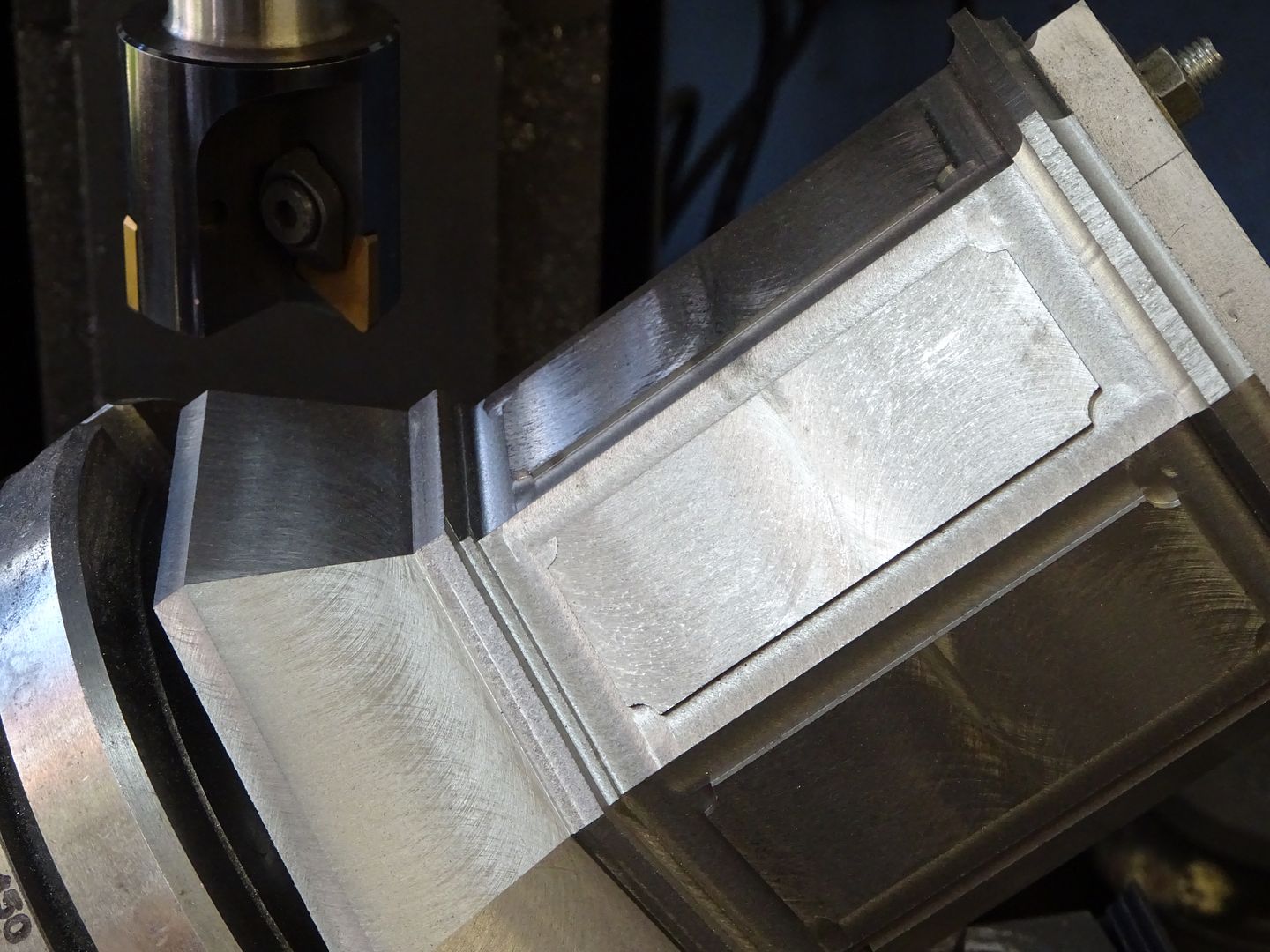

I'll give it another go with a higher feed rate but as my other cutters produve a good finish at about 150mm/min and the machine complains above that I have a feeling it is more down to the rigidity of the machine not being able to push the relatively blunt edge of these tips through the work hence the tool riding up over the work. This is the sort of finish I can get with the 40mm 3 tip tool which is far better than the Bangood gives as similar feeds

Lots to think about here as someone who has just bought a Banggood facemill with 'blue nano' cutters but not tried it yet. Meanwhile, slightly off-topic but Jason that is a beautiful piece of machining. gary Edited By gary.a.ayres on 09/09/2018 01:16:17 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in