HSS vs carbide inserts

| CHARLES lipscombe | 01/09/2016 22:13:09 |

| 119 forum posts 8 photos | Thanks to all who replied about the Eccentric Tool holder, I now understand that there are many devotees of this bit of gear out there, it can do anything a conventional HSS tool can do and that it has some pretty significant advantages when it comes to tool sharpening. To get the Eccentric Toolholder in perspective,only one question remains: does this toolholder offer any improvement in finish or other performance attribute? Of additional interest to me is that I have a roller-box attachment for my capstan lathe which uses tangential tooling and I should be able to use the sharpening jig for this also Regards, Chas |

| duncan webster | 01/09/2016 23:18:06 |

| 5307 forum posts 83 photos | The Eccentric or similar toolholder makes it dead easy to get the right geometry, but if you grind the same geometry on the end of a tool held conventionally you'll get the same results. It just takes longer, and sooner or later you have to grind away the whole end of the tool and start again. There is another one called the Wimberly http://www.wimberley-tools.com/ I have no experience of this but the concept appears to be sound, in fact I'm thinking of making one for my Perris. If you're a member of an ME club ask if anyone has got a tangential holder you could borrow to try. Edited By duncan webster on 01/09/2016 23:20:46 |

| CHARLES lipscombe | 03/09/2016 01:37:25 |

| 119 forum posts 8 photos | Thanks Duncan, I'm now convinced I should buy one! |

| Anthony Knights | 03/09/2016 08:43:55 |

| 681 forum posts 260 photos | I made my own tangential tools (left and right handed) as per "mikesworkshop.weebly.com" The flat on the front of the right hand tool is machined to my lathes centre height, which makes setting the tool height dead easy. |

| Vic | 03/09/2016 09:56:52 |

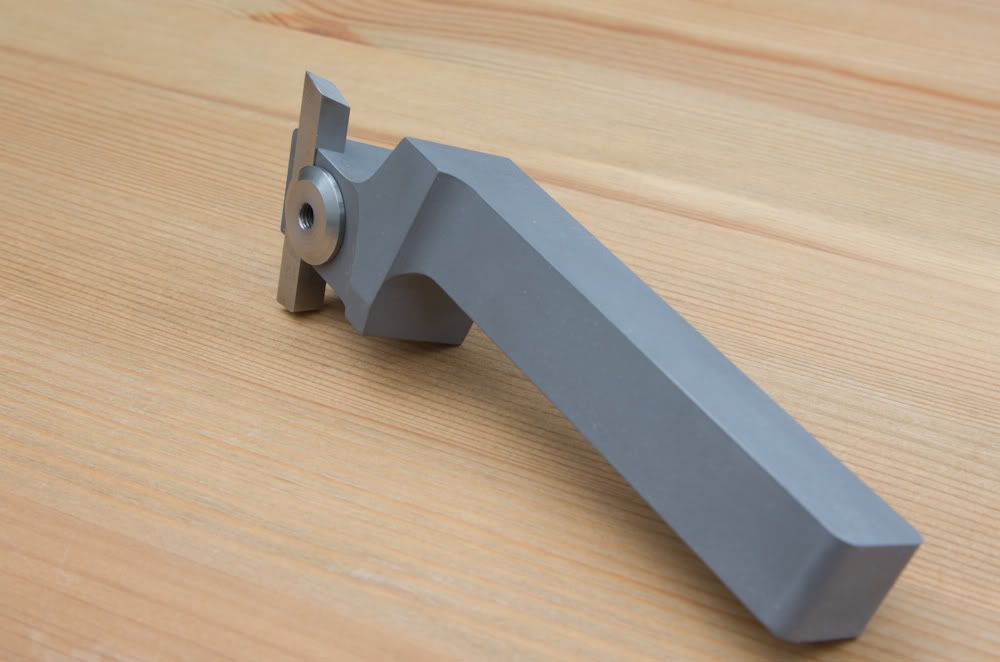

| 3453 forum posts 23 photos | Yes, they're easy to make on the mill. This is one of mine.

|

| Neil Wyatt | 03/09/2016 10:09:40 |

19226 forum posts 749 photos 86 articles | Posted by duncan webster on 01/09/2016 23:18:06:

The Eccentric or similar toolholder makes it dead easy to get the right geometry, but if you grind the same geometry on the end of a tool held conventionally you'll get the same results. It just takes longer, and sooner or later you have to grind away the whole end of the tool and start again. There is another one called the Wimberly I have no experience of this but the concept appears to be sound, in fact I'm thinking of making one for my Perris. If you're a member of an ME club ask if anyone has got a tangential holder you could borrow to try. Edited By duncan webster on 01/09/2016 23:20:46 I have a Wimberly but I'm still trying to figure out a practical way of holding it - the size of the head of the casting plus excess HSS sticking out of the back gives it about an inch overhang in a four-way toolpost and means it could only be used for small diameter work. Equally it would need a 'special' holder for the QCTP and still overhang too much. This is off the Wimberley toolholder website:

To compare I measured the overhang (beyond toopost front) of a few tools:

So the wimberley as supplied reduces the diameter of work I can tackle by 26 -30mm. What sort of overhang does a 'normal' tangential holder have? Of course I could cut the HSS in half but that would only give a small gain and defeats the object of an easy sharpen. long lifetime tool bit. My conclusion is that the Wimberley is a great idea in principle but in practice it will be best for small work on large lathes unless you have a long-travel topslide or are willing to use a custom toolpost to hold it.

Edited By Neil Wyatt on 03/09/2016 10:20:51 |

| Ian S C | 03/09/2016 13:04:52 |

7468 forum posts 230 photos | Just a note, the tangential lathe tool is not exactly new, there is an article in volume one (1898) of ME about such a tool. Ian S C |

| Vic | 03/09/2016 13:16:16 |

| 3453 forum posts 23 photos | Hasn't there been an article in one of the magazines not so long ago about making something like the Wimberly? I'm sure a mate said he was making some type of tool holder but it wasn't a Tangential. If the Tangential appeared in ME in 1898 then it's probably quite a bit older than that even. It's just that it was "reinvented" quite recently! |

| Jon Gibbs | 14/09/2016 09:40:19 |

| 750 forum posts | Posted by Jon Gibbs on 30/08/2016 18:55:30:

Posted by JasonB on 30/08/2016 16:58:38:

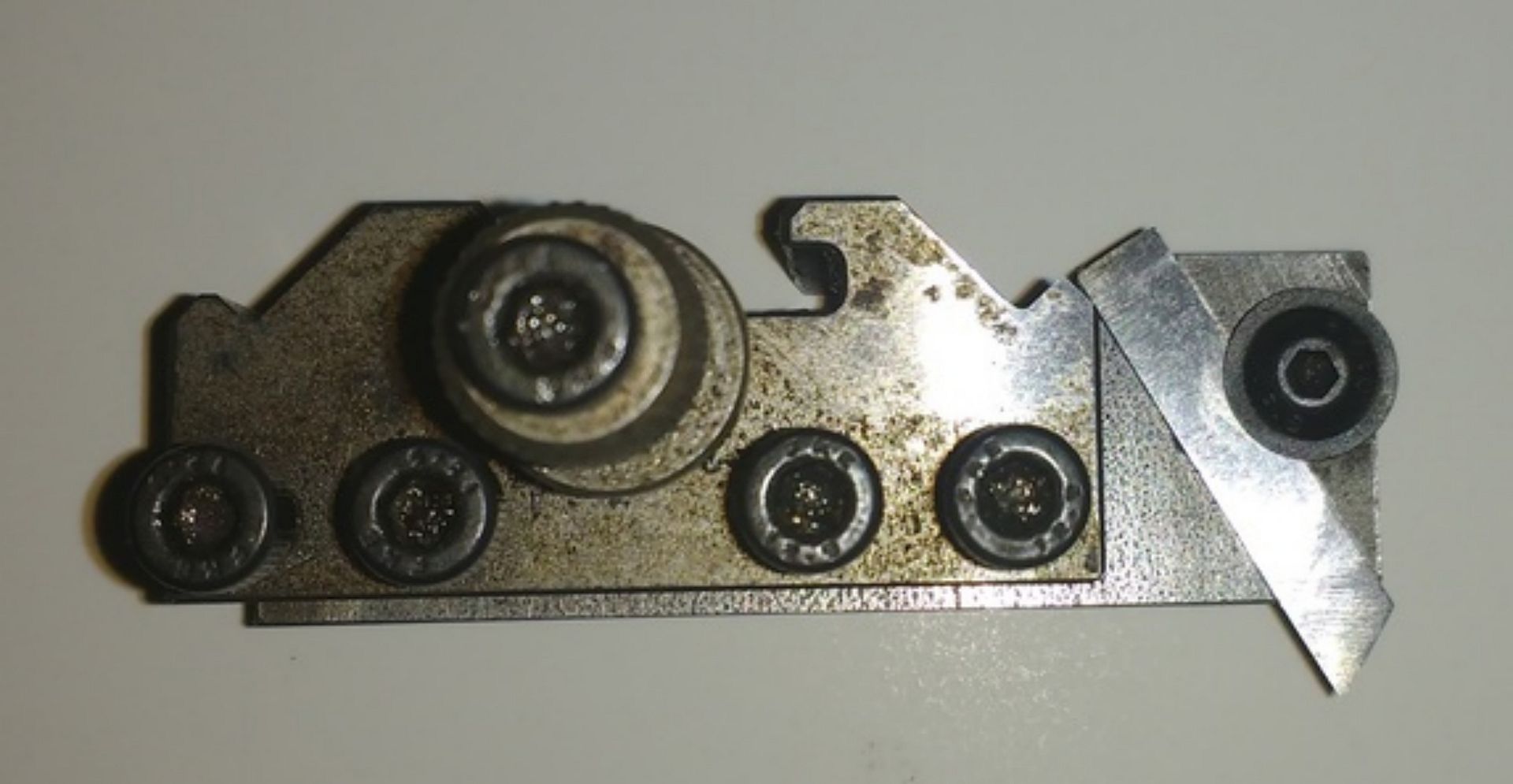

I thought they came with instructions on how to grind for 55 and 60 deg screwcutting. Well they do if you buy the Eccentric Engineering version, I made my own and they didn't come with instructions I looked at the Eccentric Engineering on-line instructions and am not very convinced because the back rake looks far too big to permit easy grinding and checking to cut accurate 55 or 60 degree thread angles unless I'm missing something? So, trying to follow Martin Cleave's 5 degree side rake recommendation for steel (page 119) which is pretty much all I thread and inspired by Jacques Maurel's article in MEW I came up with this to take 1/4" toolbits.

The toolbit is held at 30 degrees and so only one flank of the toolbit needs a lot of work (the business end for RH threading) and the 1/4" groove and screw in the holder are tilted back at the 5 degree angle so the top is held flat and doesn't need more than a hone. Sharpening is with the toolbit in the QCTP holder for speed. ...not had time to try it in anger yet though. Jon

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in