The Workshop Progress thread 2018

| JasonB | 28/12/2018 19:55:09 |

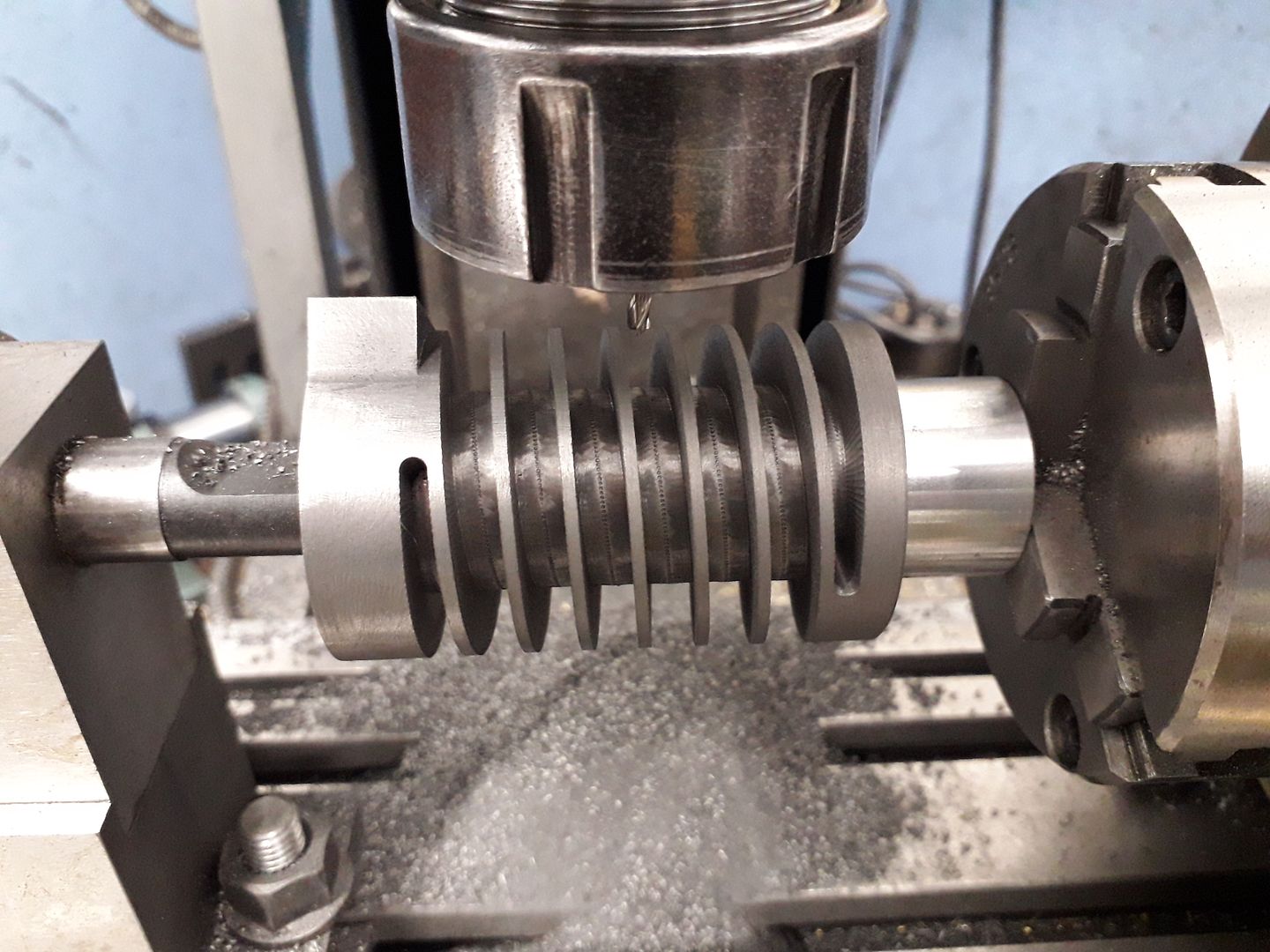

25215 forum posts 3105 photos 1 articles | As Santa failed to get the CNC mill with 4th axis down the chimney I had to resort to manual knob twiddling to make this. It is the cylinder for my current project which takes a lot of its features from an engine with spiral cooling fins.

I used the 72 turn rotary table from ARC and did it in half turn steps so the z-axis and rotary table had to be adjusted and the quill plunged 144 times per rev. I used a 7.2mm pitch which worked out nicely at 0.05mm per half turn of the handle. Did most with a 5.5mm 3-flute cutter and then swapped to a 3mm to feather out the ends. |

| Ron Laden | 28/12/2018 20:28:53 |

2320 forum posts 452 photos | Excellent Jason, but how long did that take..? |

| JasonB | 28/12/2018 20:43:12 |

25215 forum posts 3105 photos 1 articles | About 3hrs milling spread over 5-6hrs as I needed a break after each rev and it also let the motor cool. |

| David Standing 1 | 28/12/2018 21:04:26 |

| 1297 forum posts 50 photos | Posted by JasonB on 14/10/2018 15:24:05:

Can we all start a whip round to buy Jason a tripod for his camera? Edited By David Standing 1 on 28/12/2018 21:05:29 |

| Ron Laden | 28/12/2018 21:06:49 |

2320 forum posts 452 photos | Posted by JasonB on 28/12/2018 20:43:12:

About 3hrs milling spread over 5-6hrs as I needed a break after each rev and it also let the motor cool. I thought it would have taken much longer than 3 hours. Thats an impressive piece of machining and just goes to show what can be achieved on a manual machine, providing you know what you are doing of course.. |

| Mark Rand | 28/12/2018 22:32:49 |

| 1505 forum posts 56 photos | Posted by David Standing 1 on 28/12/2018 21:04:26:

Can we all start a whip round to buy Jason a tripod for his camera?

Nah. We'll just get him the plans for the George Thomas Universal Steadycam Attachment. |

| JasonB | 29/12/2018 06:56:49 |

25215 forum posts 3105 photos 1 articles | What use is a tripod when you want to move the camera about to show different views of the engine? The actual square on shots are quite steady. Mark is more on the right track with his GT giro balanced gimble but even then would still be moving the camera to various positions. |

| Russell Eberhardt | 29/12/2018 09:27:36 |

2785 forum posts 87 photos | Posted by JasonB on 28/12/2018 20:43:12:

About 3hrs milling spread over 5-6hrs as I needed a break after each rev and it also let the motor cool. That would have taken me 5-6 days and then I would have b*****ed it up near the end! Russell |

| Ron Laden | 30/12/2018 10:10:47 |

2320 forum posts 452 photos | Jason, is this an engine of your own design or is it still under wraps until its finished. I,m intrigued by the spiral cooling fins, never seen those before but they do look good. Ron

|

| Nick Clarke 3 | 30/12/2018 10:17:57 |

1607 forum posts 69 photos | Posted by JasonB on 29/12/2018 06:56:49:

What use is a tripod when you want to move the camera about to show different views of the engine? The actual square on shots are quite steady. Mark is more on the right track with his GT giro balanced gimble but even then would still be moving the camera to various positions. Phones and ipads etc are inherently difficult to hold steady IMHO If you are using a camera monopods are a good idea as is also a length of cord with a fitting for the tripod bush on the camera on one end and loop for your toes at the other. Tension the string and the camera is suddenly a lot steadier. (Works best when the camera has a central tripod bush) |

| JasonB | 30/12/2018 10:29:02 |

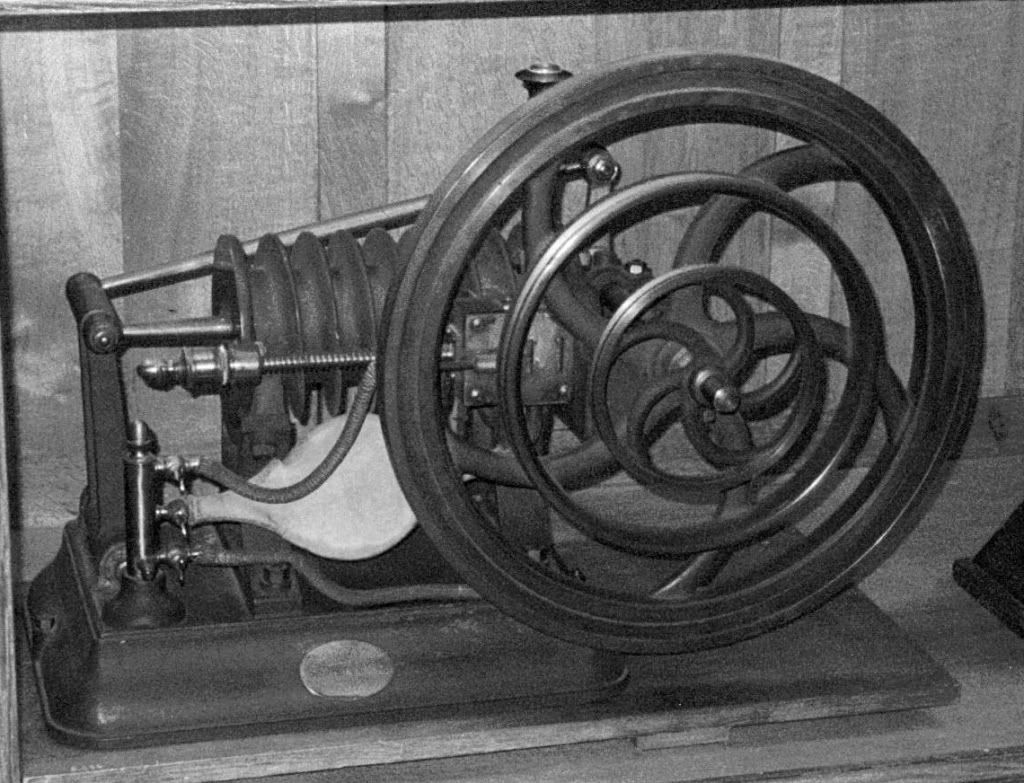

25215 forum posts 3105 photos 1 articles | Ron, it is loosly based on a 1/15th HP Forest engine of 1883. I hope it will work as a flame licker though the original was a non compression external flame ignition design which is hard to model and get running without some fancy cocktail of gasses. It will have the spiral cooling fins and the "Evans Beam" conrod arrangement of the original. I'm doing it with my usual 24mm bore so scale is about 1:2.5

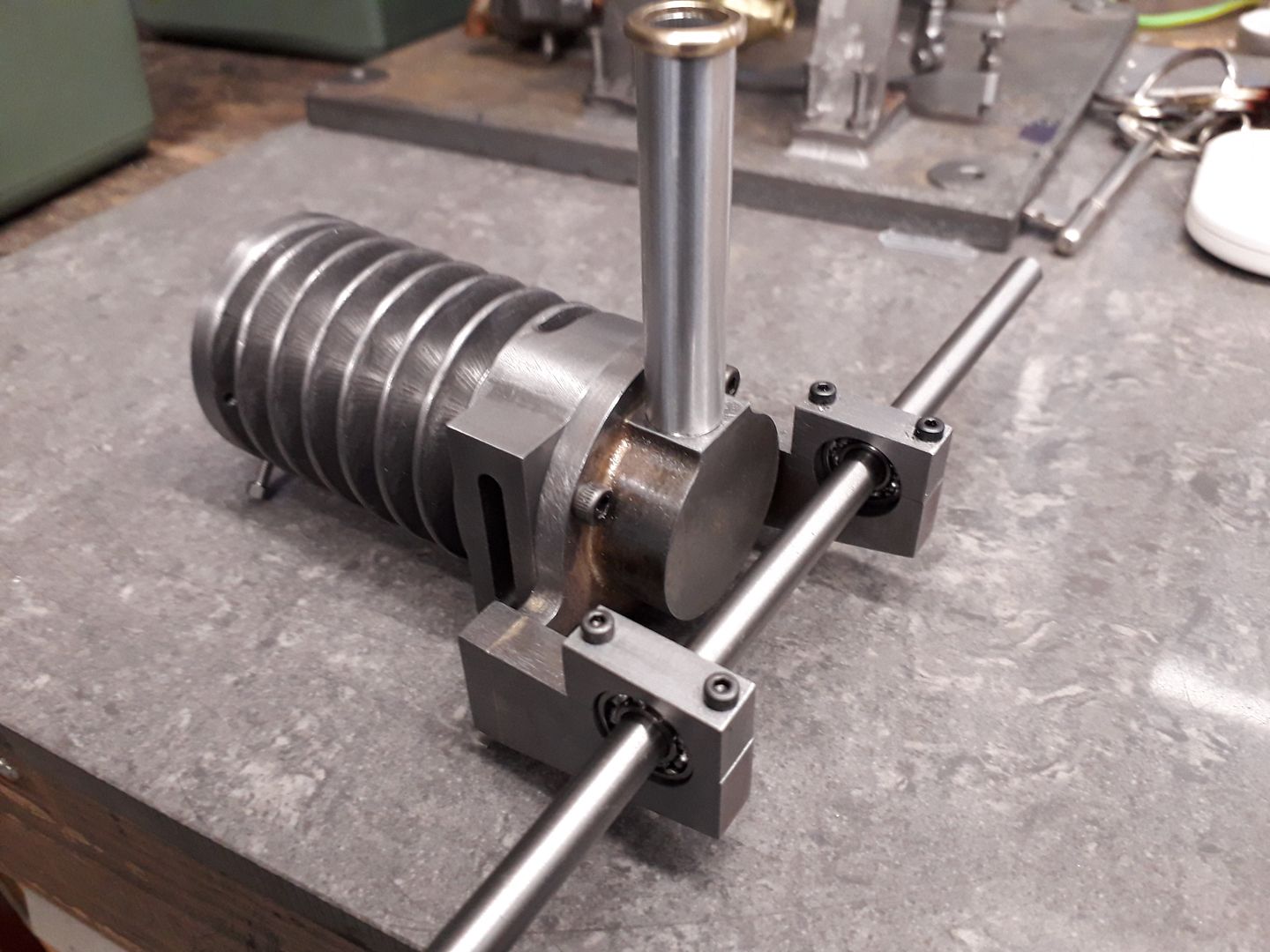

Cylinder looks a bit more like a casting now it has been fettled

|

| Ron Laden | 30/12/2018 12:39:33 |

2320 forum posts 452 photos | Interesting Jason, is a flame licker the type of engine which has an external burner next to the cylinder.? Also is that a balloon on the forest engine, it looks like one, something to do with the gas maybe..? |

| JasonB | 30/12/2018 13:21:48 |

25215 forum posts 3105 photos 1 articles | Flame licker has an external flame that is drawn into the cylinder as the piston moves one way then that hot air which was drawn in cools and sucks the piston down by vacuum. Like my Chuky if you have seen that. The Forest first draws in gas/air and then a small flame is also drawn in which ignites the gas driving the piston to the top of it's stroke and then the spent gas is exhausted on the return stroke. The balloon is known as a gas bag, you regulate the supply to a slow steady flow which inflates the bag and then it can rapidly draw in from the bag at low pressure, bag refills during the rest of the cycle. This is a 1:1 replica of the Forest in action on a Hydrogen based gas cocktail. |

| Ron Laden | 30/12/2018 13:47:47 |

2320 forum posts 452 photos | Jason, also watched the video of your Chuky engine running, great stuff, I love the sound. Look forward to seeing your new build up and running. Ron. |

| JasonB | 31/12/2018 17:19:37 |

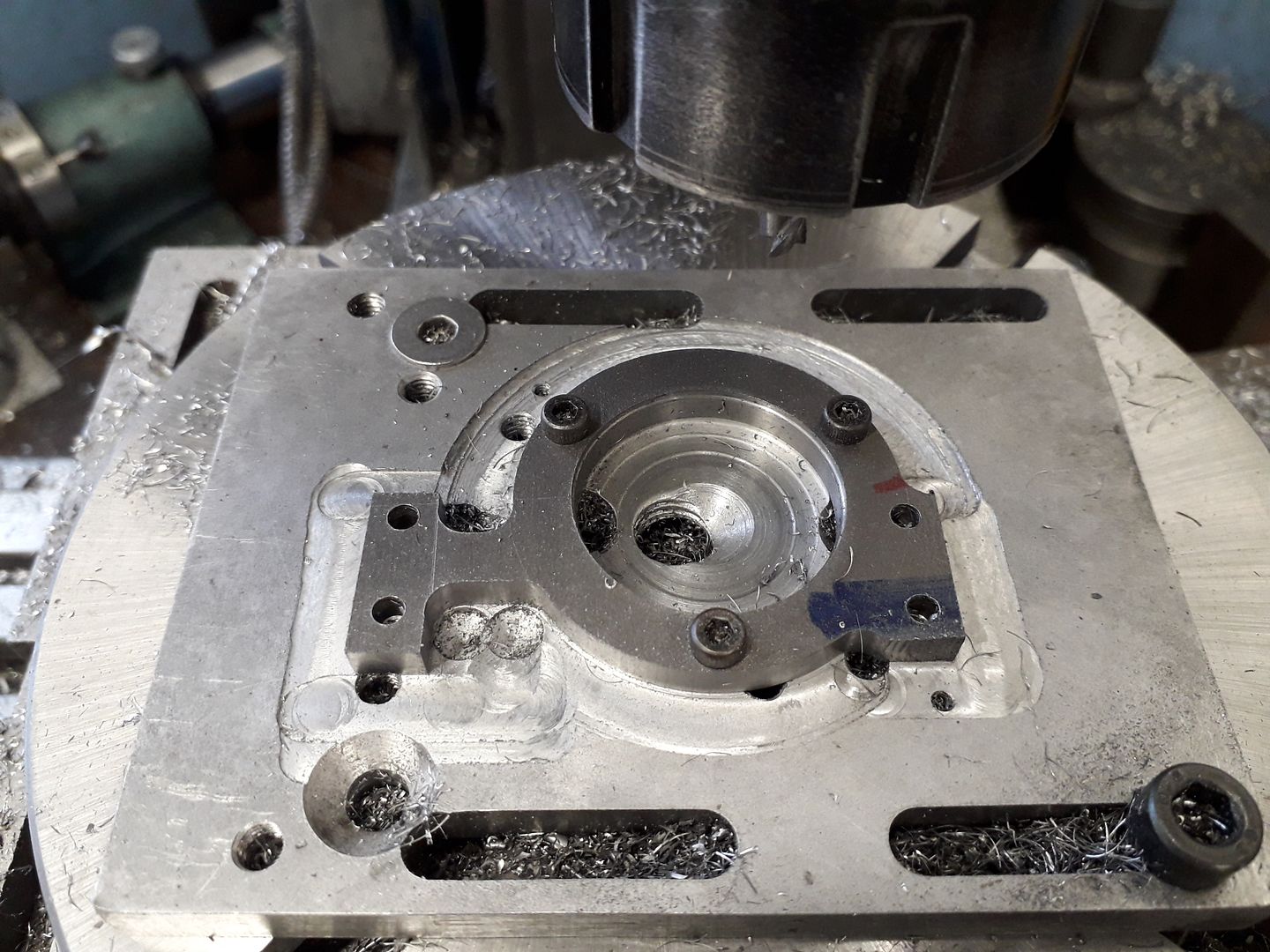

25215 forum posts 3105 photos 1 articles | My last bit of progress for this year. More rotary table work on the bracket that supports the crankshaft and takes the exhaust valve housing.

Soldered on a couple of lumps of steel and pokes a pair of holes in for the bearings

Seems to fit OK, just need to shape the bearing caps and then soften all the hard edges to make it look like a casting

|

This thread is closed.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in