Has anyone here ever modified a capstan attachment to fit a regular centre lathe?

is this just a bad idea...

| Jake Middleton-Metcalfe | 14/02/2023 13:50:09 |

| 14 forum posts 15 photos | Thank you all for the very helpful replies, I should have been a bit more specific in my original post though - There three parts I am making and they: are small bolts with a bastard thread (I have the unusual thread die) in batches of about 200 and concertina buttons which are slightly more complex and made in two parts, I would probably produce a batch of abound 400 of those parts at a time. I enclose an image to show what these are like. The tooling up and setup for making this sort of thing is not a problem, I I actually have one of the 2mt tailstock 6 tool capstan like attachments and as has been pointed out The guy bazmak who made the capstan for his mini lathe looks to have done an incredible job but sadly that path looks a bit beyond The bed turret for the sherline lathe looks incredible, it would be that exact setup which I would be Still looks a bit hard to see the best way forwards - Perhaps I need more sleep you have all provided very useful suggestions I think I just need to have a good think now on this one.

Best wishes Jake |

| old mart | 14/02/2023 13:55:37 |

| 4655 forum posts 304 photos | There are capstan attachments made for some of the Smart & Brown lathes which probably could be modified to fit your lathe, you would need a mill for the mods, though.

|

| Jake Middleton-Metcalfe | 14/02/2023 14:05:28 |

| 14 forum posts 15 photos | As mentioned in previous post here is an image of a concertina button - made in two parts |

| Clive Foster | 14/02/2023 14:44:28 |

| 3630 forum posts 128 photos | Jake I notice that a rather distressed capstan attachment is on E-Bay at the the moment (for rather too much money!). Item 154308218335 Probably too large as the turret is 5" diameter but might be worth an ask. You'd need to do the dovetail base it slides on in two or maybe three bits to get the length as it will be too long to do in one go on your mill but its not an impossible job. Frankly for the size of work you plan a partial length dovetail may well be fine. There is a nice looking Myford one :- **LINK** Item 175612996112 That looks pretty much ready to go, albeit a bit spendy. A Myford bed is of simple square edge design so, if the centre heights work, its far easier to make an adapter. Alternatively consider making something similar to the tool carrier off a tailstock turret as the basis for a cross slide mounted version. Or buy a cheap one and cannibalise it! If simple manual rotation will do an angled block to hold it at the right tilt having some sort of spring loaded registration stop inside fixed to the cross slide will suffice to mount it. Use a multi-position bed stop as I suggested in my previous post. Still need to sort a cut off slide or substitute tho'. I suspect for your mall jobs a simple hand pull down, or up, device pivoting on a rod behind the lathe bed might work. Sharp too and stop spring to work against. Clive

Edited By Clive Foster on 14/02/2023 14:45:24 |

| JasonB | 14/02/2023 14:52:03 |

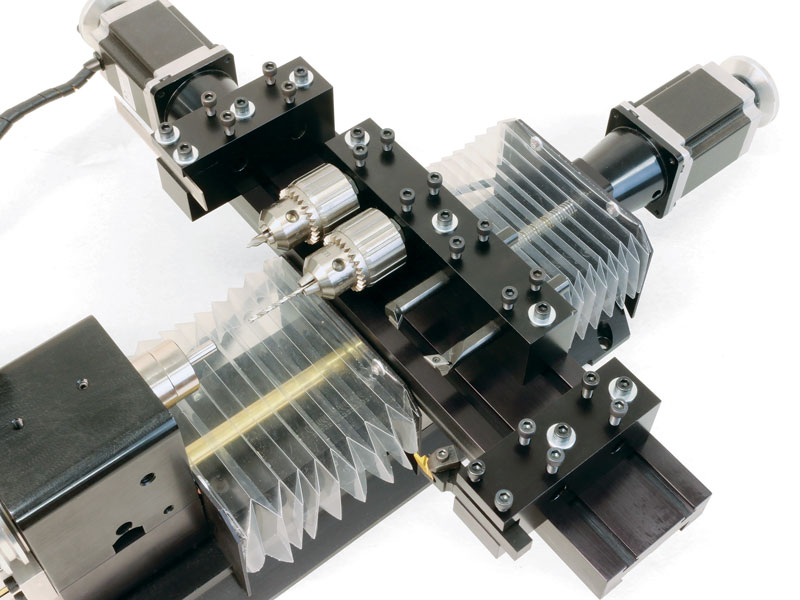

25215 forum posts 3105 photos 1 articles | In theory it should be possible to set up the tailstock type tools so only a single stop is needed. It needs some initial time spent on setting up the tools so that they all extend the correct distance from the stop which may entail making side lock type holders for things like ctr drills to bring them out to a similar standout of the larger items of tooling such as running down boxes and die holders. Conversion to lever feed would also help but no reason not to just wind the barrel out to a improvised stop. I think it was mentioned earlier about arranging several tools along the cross slide, it will depend on available movement but as your items are quite small the tooling could be a lot closer together than this picture of a Sherline CNC shows. Again if set to protrude the right amount then a single stop would work and feed the cross slide in to easy to remember increments of the handwheel.

|

| duncan webster | 14/02/2023 14:58:54 |

| 5307 forum posts 83 photos | For making bolts I don't think a capstan helps. Face off and turn thread diameter to a length guy front tool post and saddle stop. Thread,- tailstock die holder Part off - rear tool post and saddle stop. Not sure about buttons not enough detail. |

| Journeyman | 14/02/2023 15:57:02 |

1257 forum posts 264 photos | How about something like this from *** Mikes Workshop ***

With a bit off work setting tooling and some additional stops could be made to function. With a lever operated tailstock could be even better. John Edited By Journeyman on 14/02/2023 15:57:57 |

| Andrew Johnston | 14/02/2023 17:07:49 |

7061 forum posts 719 photos | Having used both to make nuts, bolts and studs, personally I think that a repetition lathe is better suited than a capstan unit. Although, as always, it comes down to tooling. I have a Britan which has a small footprint, similar to a Myford. I normally use a Coventry diehead for external threads. But a clever holder with dog clutches allows an ordinary split die to be used almost as quickly as a diehead: Andrew |

| bernard towers | 14/02/2023 18:04:51 |

| 1221 forum posts 161 photos | It is possible to use a tailstock turret to make bolts, I use dedicated cutters similar to end mills with a thru hole of the correct size for the bolt stock and then thread and part off. |

| Zan | 14/02/2023 18:41:18 |

| 356 forum posts 25 photos | There’s a myford capstan on sale for £575 in Lathes.co.uk |

| mgnbuk | 14/02/2023 19:47:36 |

| 1394 forum posts 103 photos | Two Myford bed mounted capstan units, a cut-off slide, a cross-slide mounted capstan unit + capstan tooling on Ebay at the moment - search "Myford" & set "Newly listed" then scroll down. Nigel B. |

| Hopper | 15/02/2023 00:48:16 |

7881 forum posts 397 photos | Posted by Jake Middleton-Metcalfe on 14/02/2023 14:05:28:

As mentioned in previous post here is an image of a concertina button - made in two parts No idea, but presumably there is a male thread on the white piece and a female thread in the silver piece holding the two together? It does not look like a capstan set up would save much time over what can be done with existing gear such as form tools and lever tailstock if you start off with material of the correct OD. You might look at making some capstan-lathe style roller boxes to mount on the tailstock turret. These consist of a pair of small rollers to hold the work steady while a pre-set cutting tool turns the job down to the reduced diameter as it is feed along. Then a miniature Coventry diehead type thing to do the male thread and a tapping head to do the female thread quickly without smashing the tap into the blind hole. The domed end on the silver piece could be put on using a combined parting tool/form tool as the final operation. Will need a bit of polishing afterwards to finish it off to such a standard but you are going to have to do that anyway. Making bolts is definitly lever tailstock territory. Or using hexagon stock and a multi-stop carriage stop you can have a stop to set the amount of bar sticking out, then the amount of shank turned down (or roller boxed down) then apply thread with die head in tail stock. Then part off using carriage stop again, putting the chamfer on the hex halfway through the parting process, or make a combined parting/chamfering form tool. The cross hole is a bit special, especially in the workholding aspect. Special jig required etc. But time could be saved by making a drill bit with a surrounding hardened silver steel sleeve shaped as a countersink cutter, so all done in one motion. Edited By Hopper on 15/02/2023 00:50:51 |

| John Reese | 15/02/2023 01:23:59 |

1071 forum posts | I adapted a Hardinge turret to a South Bend 10K lathe. I managed to get the holes in the turret concentric with the spindle within .001". |

| Hopper | 15/02/2023 10:19:37 |

7881 forum posts 397 photos | Posted by Zan on 14/02/2023 18:41:18:

There’s a myford capstan on sale for £575 in Lathes.co.uk And one on eBay for 650 Quid. Ambiguously labelled as a tailstock though. LINK Not sure if it might be a bit big for a mini lathe though? Edited By Hopper on 15/02/2023 10:20:07 Edited By Hopper on 15/02/2023 10:22:22 |

| Jake Middleton-Metcalfe | 03/03/2023 13:01:56 |

| 14 forum posts 15 photos | Well everyone was very helpful on this question and I was so impressed by the array of various solutions to the problem of speeding up production. In the end after a lot of investigation, deliberation and very careful searching I was able to find a myford C7 capstan lathe which I am very happy with. Space was found and deals were done.

I would like to thank everyone who posted responses to this thread, although I may not have replied to each post individually I did carefully consider what every single poster said. Best wishes Jake |

| Nigel Graham 2 | 04/04/2023 22:52:24 |

| 3293 forum posts 112 photos | Clive, Noel - You don't need the complexity of electronics and motors to automate the indexing. You'd already indicated turret and capstan lathes have this feature as a matter of course, and entirely mechanically; and though I don't know it worked I doubt it was very complicated. The mechanism also indexes the adjustable depth-stops, so the Myford version was perfectly conventional in that regard. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in