Indexable threading tool tips

| Tony Pratt 1 | 08/11/2022 15:17:04 |

| 2319 forum posts 13 photos | I agree with Andrew & whatever method you use the tip has to be set up correctly to give a symmetrical form. You may have also set the required 27.5 degrees from the wrong axis? Tony |

| Martin Kyte | 08/11/2022 15:28:29 |

3445 forum posts 62 photos | The chuck side flank will be formed by the tool tip, the opposite flank will be formed by the topslide infeed and angle at which it was set. If the tool is not square on to the work and is say angled back towards the tailstock the chuckside flank will be at too shallow an angle and the other flank whatever the topslide was set to and composed of series of 5 thou steps. For set over method which helps, when using dodgy home ground tools and no TC grinder, a slightly more pointed tool could be used with the front flank set at the correct angle and then the rear flank will be generated correctly with the topslide infeed. If you are using tips then the tool gemetry should be correct so if you wish to use the set over then an angle of slightly less than the half angle will ensure that a scrape is taken on the rear flank and the thread angle will be correct. However you either have to resort to geometry and advance the cross slide whilst retracting the topslide a little to acheive the correct thread width or go overly deep. If you are using tipped tools then there is no point and as Andrew has said you may as well go straight in to depth and then you can use the topslide to widen the thread untill it fits. regards Martin Edited By Martin Kyte on 08/11/2022 15:29:05 Edited By Martin Kyte on 08/11/2022 15:30:23 |

| JasonB | 08/11/2022 15:46:11 |

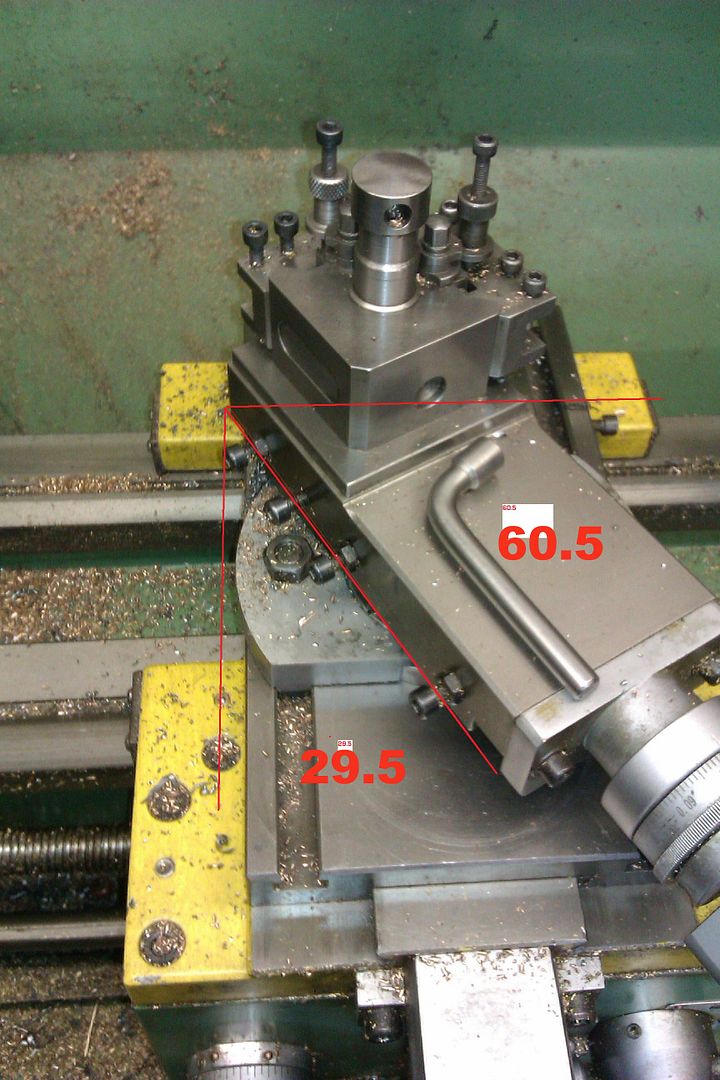

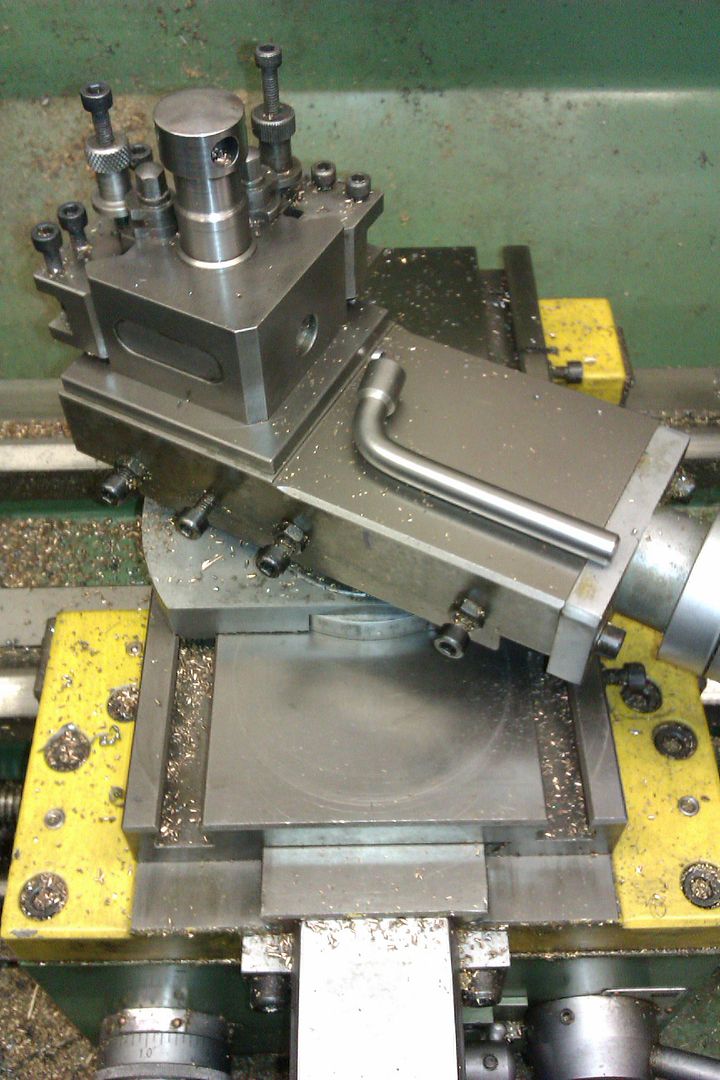

25215 forum posts 3105 photos 1 articles | Your top slide should look something like this but a couple of degrees different for Whit

Not like this

Though Like Andrew I don't set my topslide to the half angle, just straight in with teh cross slide Edited By JasonB on 08/11/2022 15:46:45 |

| Peter Simpson 3 | 08/11/2022 16:05:43 |

| 122 forum posts 2 photos | If a cut the thread using the cross slide only the thread form is perfect. I will check the top side angle and adjust as required. many thanks Peter |

| Clive Foster | 08/11/2022 16:22:06 |

| 3630 forum posts 128 photos | +1 for Jasons excellent pictures. My top slides live at 25° with the arrangement shown in Jasons first picture. Because I use the Zero-to-Zero method it doesn't really matter, within reason, what angle the top slide is at. The lathe does all the top slide in-feed calculations for me. What matters is that the (sharp) tool-bit is exactly perpendicular to the job and that all the backlash is taken out when setting up. Jon makes a good point about the tendency of Zero-to-Zero to end up with excessive in-feed and too small a minor diameter when the tool point is too sharp. Given that partial profile inserts do the same thing on any size beyond the smallest of their specified range I don't believe that industry considers, within reason, a little undersize on minor diameter a great worry for ordinary threading jobs. As regular forumites know (ad-nauseam) I consider the most important requirement if any way of doing any job is to be suitable neophytes and inexperienced folk is that it be easy to figure out what went wrong if something doesn't go as per plan. Ideally it should be possible to step back to the error point and sort things out before the job is scrapped. With too sharp a point on the tool Zero-to-Zero initially gives too large a minor diameter so the the mating part will not screw on. So the point of failure is safe and the extra feed needed to allow the mating part to fit can be applied in a controlled manner. Once a fit is achieved the operator can choose between accepting an undersize minor diameter or grinding back the tool tip sufficiently to eliminate the excess in-feed on a replacement part. Effective though it can be the Martin Cleeve side feed correction method is heavily dependant on operator skill and experience. I was taught it, I can use it but "My God its easy to get lost". Clive |

| Peter Simpson 3 | 09/11/2022 16:18:13 |

| 122 forum posts 2 photos | Many thanks for all of you input into this topic. I went back into the workshop to experiment again. Checked the set up again using all you input and realised that I had set the top slide as per the "wrong" photo above. Set the top slide as per the correct photo and cut a thread which turned out to excellent. |

| mark costello 1 | 09/11/2022 19:02:57 |

800 forum posts 16 photos | You are not the first one to do this. 13"ODx 3"x3" threaded spigot x 29 years ago with many bad words from the Foreman and I have never forgot it. I guess the lesson served it's purpose as I never have forgot it, but it was a bit harsh. |

| old mart | 09/11/2022 20:49:35 |

| 4655 forum posts 304 photos | I never rotate the compound to do threading, even 5tpi ACME but the Smart& Brown model A is probably more heavily built than most hobby lathes. As for the photographs by Jason showing the correct angle, that is fine as long as newcomers are aware that the tool tip axis must be parallel to the cross slide axis and not angled with the compound. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in