Screw cutting problem

| John Haine | 15/03/2022 22:20:50 |

| 5563 forum posts 322 photos | I just reminded myself that the Mach3 threading wizard has an infeed angle parameter you can set. For metric/UN threads this is set to 29 degrees. Obviously there is no topslide involved but the wizard will make a horizontal offset on each cut so the tool effectively advances at that angle. Here's a thread I cut for an ER16 collet closer using a home ground HSS tool, speed ~215 rpm. Despite what they say Mach3 can thread perfectly well. |

| Hopper | 16/03/2022 00:30:37 |

7881 forum posts 397 photos | Posted by Bazyle on 15/03/2022 19:36:20:

Er, i know lots of people like the topslide parallel but that's not what it is for. Lots of early lathes didn't have one so it was added to enable tapers etc, You should be able to set it over and leave it there, except for the infernal nuisance of Whitworth and BA being different from unified and metric. Except on the Myford the top slide handle gets in the way of the cross slide handle. Standard American procedure is to keep top slide at 30 degrees from the lathe axis so it doez not foul the tailstock. In industry in Oz and Africa I only ever saw the top slide left permanently parallel to the axis. Screwcutting was all done by advancing topslide by half of the infeed of the cross slide. It works for both 55 and 60 deg threads as you only need most of the cutting done by the leading edge, not all. The trailing edge, even with negative rake, takes a fine finishing cut on that flank. Topslide was usually set once with a dial indicator and left there so it turned perfectly parallel on small jobs or measured distance to a shoulder etc. You only ever disturbed it on the rare occasion of turning a short taper. Certainly not for screwcutting which was a regular task.

|

| SillyOldDuffer | 16/03/2022 11:04:58 |

| 10668 forum posts 2415 photos | Posted by Hopper on 16/03/2022 00:30:37:

Posted by Bazyle on 15/03/2022 19:36:20:

Er, i know lots of people like the topslide parallel but that's not what it is for. Lots of early lathes didn't have one so it was added to enable tapers etc, You should be able to set it over and leave it there, except for the infernal nuisance of Whitworth and BA being different from unified and metric. Except on the ...

Might have changed since the early lathes! In Jason's picture, where he shows which way round the top-slide is angled for screw-cutting, it can be seen the QTCP hasn't been turned yet to present the cutter at a right-angle to the job. The QTCP is in it's normal position at right angles to the top-slide.

I have a 4-way tool-post rather than a QTCP and it's accurately positioned at a right-angle to the top-slide by a spring-detent. Definitely designed to be used at right-angles, with a positive lock. The tool-post can be clamped at any other angle to the top-slide but the friction grip is reduced and the detent inoperative : not ideal for heavy cutting, but plenty good enough for threading. An advantage of having the top-slide at an exact right-angle is the tailstock is notched to clear it. The extra space is used to widen the saddle for extra stability. There doesn't seem to be any advantage in angling the top-slide when screw-cutting with a 'modern' lathe. (i.e the boxy looking machines designed with an eye on carbide a decade or two after WW2.) You can either go straight in to screw-cut, which is what I usually do, or reduce the cutting load by periodically advancing the top-slide slightly on repeated passes. Not doing a hard-sell on straight-in threading as being the best way to screw-cut on all machines! I think it depends on the condition and design of the lathe, the cutter type, and the material. Dave

|

| Hopper | 16/03/2022 11:18:47 |

7881 forum posts 397 photos | Yep, it's all horses for courses. And every jockey has his own preferred riding style. But every punter knows the winner of course! |

| John Reese | 16/03/2022 23:23:25 |

1071 forum posts | JasonB' photos are n excellent description of how to set the compound slide for threading right hand threads cutting toward the headstock. For left hand threads and internal threads the compound slide must oriented differently. My rule of thumb is set the compound parallel with the trailing edge of the tool then move it about 1/2* toward perpendicular with the work. That works when feeding with the compound (flank feed). When feeding with the cross slide (plunge feed) the orientation of the tailstock is irrelevant. |

| Clive Foster | 17/03/2022 09:53:16 |

| 3630 forum posts 128 photos | As has been said, in normal lathe use the primary advantage of setting the topslide at an angle is to generate clearance between the top and cross slide handles or topslide and tailstock depending on whether its at 90° to the bed or parallel to it. Small amchines tend to be cramped. A secondary advantage is that it reduces the possibility of error should the topslide not be exactly at 90° or parallel if using it to apply a cut. Getting it dead right and ensuring its always dead right can be a pain. Especially on smaller machines with only the basic equipment that home shop guy/gal budget can stretch to. Odds are that any such cut will be done mid job with no chance to verify settings. Often the last cut that has to be spot on to make the job just right too! Setting at 90° to the bed always seems a bad idea to me because tool in feed cutting forces need to be applied via both cross slide and topslide screws. Which generally are fairly slender and not exceptionally stiff on our (usually) smaller lathes. Unless the topslide is locked solid. But most lathes don't have provision for that without disturbing gib adjustments. With two screws in the way you have two lots of backlash clearance floating around so if the cut goes into "judder in and out" mode it can be twice as bad. No nice when parting off decides to go wrong. When screwcutting the big advantage of setting the topslide at an angle is that you can use the Zero-2-Zero method which is by far the easiest to set-up and implement. Forget the American insistence on setting at exactly 30° which requires maths to calculate feed and, along with the lantern tool post, provides further proof that our colonial cousins are not quite bright when it comes to lathes. The Zero-to-Zero method lets you set the topslide at any sensible angle, mine lives at 25° which does Whitworth, American and Metric just fine, because the lathe actually does the infeed calculations for you. When using Zero-2-Zero you initially touch the tool tip to the job and set both top and cross slide dials to zero then move the tool clear of the end of the job and feed the cross slide forward by the depth of the thread you wish to cut. Straight out of the book usually. Re-set the cross slide dial to zero and pull back the topslide to gain clearance. Make the cuts with the cross slide set to zero and apply feed with the topslide. When both dials are at zero and all spring cuts are worked out you have cut what you set. Which probably doesn't actually fit as, in the home shop, the minor diameter tends to come out too large. Generally our home ground tools aren't exactly the correct tip shape and when using factory carbide or chaser tooling we don't have the correct infeed data to generate a thread right first time. Understanding the clearances involved and their interaction with tip shapes from the usual "lots of triangles" picture in the Zeus or other reference book is hard. Easy enough to add a bit of extra feed to the cross slide, shaving things down until they do fit. If the cross slide zero is altered to refect this any subsequent threads will fit perfectly. Organised folk will make a note of the extra feed needed for chasers et al. I've had my Johannesson / SKF chasers for 20 years and not got round to it. Biggest disadvantage of Zero-2-Zero is that it needs a slightly larger run out groove at the end of the thread. 1 1/2 pitches minimum rather than 1. But who is that accurate at dropping the halfnut. Hardcore manual machinists consider single tooth clutches and Ainjest attachments cheating. Clive |

| Ramon Wilson | 17/03/2022 09:55:15 |

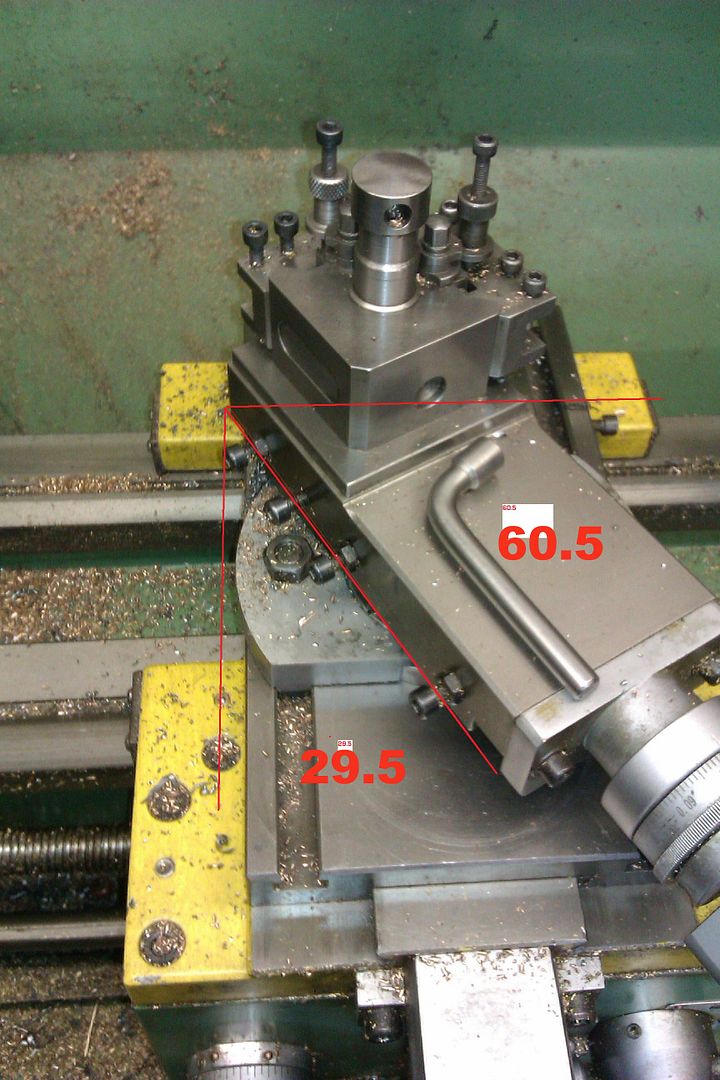

1655 forum posts 617 photos | Hello Phillip, Over the years I have screw cut many items on my S7 without using the compound slide. This is permanently set at 15 degrees for normal turning for no other reason than to give clearance to the tail stock. I only change this position if the specific turning warrants it so it remains at 15 degrees for screw cutting too but of course is not used to apply a cut. You can see the corner of the compound slide still at that angle in this image. The image is from the build of an Atomatic 5cc diesel which required several parts to be screwcut - L&R/H all done as above which can be seen in this view of the parts. I usually coat the part with a felt tip pen and scratch the surface with the tool to check the pitch then depending on material and depth of thread required take at least a 10 to twenty thou cut reducing as the depth increases and taking spring cut passes at stages without putting a cut on - I have no aids other than the cross slide movement so speeds are a bit slow to prevent mishaps if working to a shoulder. One tip I was shown at work many years ago was on that last cut or so if the gauge/mating part won't quite go on is to make a cut on the same setting but apply a very slight drag on the saddle handwheel by hand - this will give a scrape to the rear face of the thread without digging in. An acquired skill but one worth trying to master - try it out with plenty of material to go first! BTW - Shouldn't that 29.5 degrees in your image be 27 .5 Jason Regards - Tug Edited By Ramon Wilson on 17/03/2022 09:58:30 |

| Andrew Johnston | 17/03/2022 11:38:23 |

7061 forum posts 719 photos | Posted by Clive Foster on 17/03/2022 09:53:16: Hardcore manual machinists consider single tooth clutches and Ainjest attachments cheating.More fool them, but they probably also regard the electric motor as an invention of the devil. Andrew |

| Douglas Johnston | 17/03/2022 11:43:04 |

814 forum posts 36 photos | When it comes to screwcutting I think the set over technique is beneficial when using a small lathe. I have a Myford Speed 10 lathe and almost always use the top slide set over and the lathe seems happier this way. Chunkier lathes probably don't benefit to the same extent. Doug |

| John Haine | 17/03/2022 11:45:42 |

| 5563 forum posts 322 photos | As has been pointed out you don't need to angle the topslide, just move it to the left slightly for each cut by an amount calculated to give the same effective angle. |

| Hopper | 17/03/2022 12:02:26 |

7881 forum posts 397 photos | Posted by Andrew Johnston on 17/03/2022 11:38:23:

Posted by Clive Foster on 17/03/2022 09:53:16: Hardcore manual machinists consider single tooth clutches and Ainjest attachments cheating.More fool them, but they probably also regard the electric motor as an invention of the devil. Andrew Funny you should say that... I was just reading a 1929 ME article on making a small sensitive drilling attachment for the lathe tailstock. The author T Dyer describes drilling a tiny #75 hole in an injector "by foot power and no broken drills. "The writer prefers foot power for small delicate jobs, as one's foot seems to work in unison with one's mind, and sort of senses trouble before it actually comes along, which is more than can be said for a countershaft."

|

| phillip burbank | 17/03/2022 12:04:13 |

7 forum posts | I was using.g the setting over of the compound slide as that was the way that I was taught to screw cut when I wasvan apprentice ( 50 yrs ago). The smallest lathe that we used was a Colchester Student which seemed huge to a 15yr old lad who had never used a lathe before,and compared to the Myford that I now own it was. Everyone has given me lots to think about on this topic and I will try out most of the suggestions forwarded. When Hopper came back to me very early on in the discussion he answered a question that I hadn't even given any thought to I.E. not being able to set the compound slide over to 30 degrees from square onto the axis. I have forgotten a great deal that I did when an apprentice, but wasn't a machine apprentice anyway but a fitter. I have just had a thought aswell and it's 55yrs not 50yrs as I first said.

|

| Hopper | 17/03/2022 12:06:41 |

7881 forum posts 397 photos | Posted by Ramon Wilson on 17/03/2022 09:55:15:

Hello Phillip, Over the years I have screw cut many items on my S7 without using the compound slide. This is permanently set at 15 degrees for normal turning for no other reason than to give clearance to the tail stock. I only change this position if the specific turning warrants it so it remains at 15 degrees for screw cutting too but of course is not used to apply a cut. You can see the corner of the compound slide still at that angle in this image. The image is from the build of an Atomatic 5cc diesel which required several parts to be screwcut - L&R/H all done as above which can be seen in this view of the parts. I usually coat the part with a felt tip pen and scratch the surface with the tool to check the pitch then depending on material and depth of thread required take at least a 10 to twenty thou cut reducing as the depth increases and taking spring cut passes at stages without putting a cut on - I have no aids other than the cross slide movement so speeds are a bit slow to prevent mishaps if working to a shoulder. One tip I was shown at work many years ago was on that last cut or so if the gauge/mating part won't quite go on is to make a cut on the same setting but apply a very slight drag on the saddle handwheel by hand - this will give a scrape to the rear face of the thread without digging in. An acquired skill but one worth trying to master - try it out with plenty of material to go first! BTW - Shouldn't that 29.5 degrees in your image be 27 .5 Jason Regards - Tug Edited By Ramon Wilson on 17/03/2022 09:58:30 Beautiful work Ramon. I am in awe. And great tip about dragging on the handwheel to clean up the trailing flank. Much less faff than winding the topslide back past the backlash and then back a thou or two before the 0 mark. YOu learn something new on this forum every day. |

| JasonB | 17/03/2022 13:06:26 |

25215 forum posts 3105 photos 1 articles | The staged photo was taken some years ago for a member who was chewing up an attempt at a metric thread, would not have wanted to confuse them more with those old imperial angles One of the main reasons I keep my topslide set parallel (by dti) is that the carriage handwheel is not that sensitive and the divisions on the wheel are 0.020" each so not so easy to put on a cut of known amount. So the topslide handwheel scale gets used for measured cuts, setting the length of say a spigot or spacing out cooling fins on aircooled cylinders, Oh and tapers too. Clearance does not seem to be much of a problem and if it does get a bit tight I have the extended Dickson holders or more often these days use a DCMT insert which gives all the reach needed. J

PS Ramon, any progress on the compound or does the time of year mean gardening and flying have now taken over |

| robjon44 | 17/03/2022 13:55:35 |

| 157 forum posts | I have to agree with Andrew Johnston's comment above about people who insist on living in the past where slavishly adhering to ancient practices on the off chance someone might award you some brownie points is a complete loser, there is no real way to shift some peoples mind set out of the single furrow they insist on ploughing. Having served an apprenticeship as a skilled manual turner from 1960 I moved up through the ranks of automatic lathe setter & eventually Programmer Setter Operator of CNC lathes the size of a Transit van, all along the way this mind set was evident, even though change gears, flat belt drives & putting chalk marks on the moving parts had been consigned to the dustbin of history. One day, not long before he retired my dear old dad who had served his apprenticeship as a Fitter/ Turner prior to WW2 & was now the Chief Planning Engineer of the company where we both worked was in the machine shop, he looked through the armoured glass window where it was all happening & said "bloody hell boy, I wish we'd had all this in 1938" So I can keep internal & external CCTV cameras, 3D graphics when running simulations of new programs & my own personal favourite Iris Recognition then, if that doesn't keep meddlers out nothing else will. Bob H |

| Ramon Wilson | 17/03/2022 14:25:58 |

1655 forum posts 617 photos | Posted by robjon44 on 17/03/2022 13:55:35:

I have to agree with Andrew Johnston's comment above about people who insist on living in the past where slavishly adhering to ancient practices on the off chance someone might award you some brownie points is a complete loser, there is no real way to shift some peoples mind set out of the single furrow they insist on ploughing. Having served an apprenticeship as a skilled manual turner from 1960 I moved up through the ranks of automatic lathe setter & eventually Programmer Setter Operator of CNC lathes the size of a Transit van, all along the way this mind set was evident, even though change gears, flat belt drives & putting chalk marks on the moving parts had been consigned to the dustbin of history. One day, not long before he retired my dear old dad who had served his apprenticeship as a Fitter/ Turner prior to WW2 & was now the Chief Planning Engineer of the company where we both worked was in the machine shop, he looked through the armoured glass window where it was all happening & said "bloody hell boy, I wish we'd had all this in 1938" So I can keep internal & external CCTV cameras, 3D graphics when running simulations of new programs & my own personal favourite Iris Recognition then, if that doesn't keep meddlers out nothing else will. Bob H

Well yes I guess I do live in the past where conventional machining is concerned - on basic kit found in the home workshop. I too have had my time on transit van sized Haas machining centres but when I step into my workshop with my Super 7 that has served me well and the post war Linley Milling machine the same then reality strikes home and I use practices that suit the kit and the skill level required for the job. I've always tried to help people on here who are beginners or are struggling to achieve something by giving an example to go by. Never thought I'd be considered a 'Medlar' nor that I might be seen as attempting to score brownie points but there you go - something I guess I'll have to live with

Thanks for the comments Hopper - just for interest all done on my S7 and Linley mill and from solid - no castings were harmed in the making. A full build log is here if you are interested. Oops there I go again, looking for brownie points - bugger. Jason - some progress has been made - basic assembly all okay and all cast finished. Control Line currently has the upper hand over and yes some serious developments in the garden too but hope to be back on it in the Autumm. Hope you are keeping well

Regards - Ramon |

| Andrew Johnston | 17/03/2022 14:55:45 |

7061 forum posts 719 photos | Posted by Ramon Wilson on 17/03/2022 14:25:58:

...be considered a 'Medlar'...

Nothing wrong with medlars, got one in the garden. They look horrible after bletting, but taste lovely. Andrew |

| Neil Lickfold | 17/03/2022 15:00:47 |

| 1025 forum posts 204 photos | It is common to drag your hand on the hand wheel of the saddle at the start of all the passes, especially on older lathes with plenty of back lash everywhere. Also to nip up the top slide to reduce it from moving, unless doing the angled topslide way, or the Hardinge way as I call it. There are many ways to skin a cat as they say, and nothing like experience. We are very fortunate for the likes of Ramon who have gone out of their way to record and keep such a great build log of not only how it's done, but shows the equipment it is done on. Now days we are spoilt for choices to learn, and youtube I find has some great things, but there is also some rather nasties their as well. If you never know anything about engineering, I always think some of the old books and booklets are always a great starting place, then move onto where ever for the knowledge. Apprenticeships are no longer what they used to be that is for sure and most it seems are just too keen on the newer ways than learning the old skills. A simple example is making a thread cutting tool, either internal or external. |

| Tony Pratt 1 | 17/03/2022 15:01:18 |

| 2319 forum posts 13 photos | Posted by Clive Foster on 17/03/2022 09:53:16:

Hardcore manual machinists consider single tooth clutches and Ainjest attachments cheating. Clive Clive, where did that 'pearl of wisdom' come from? Tony |

| Ramon Wilson | 17/03/2022 16:46:28 |

1655 forum posts 617 photos | Inverted 'commers' Andrew Tug

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in