Grinding tool bits

| Russell Eberhardt | 01/10/2021 19:24:01 |

2785 forum posts 87 photos | The curvature on the front face of the tool won't cause any problem. In fact it can be an advantage as you only need to hone the top and bottom of the front face so much quicker. To cut down a long toolbit I just use an angle grinder with an abrasive (not diamond!) cutting disk or occasionally the notch and hammer technique. Russell |

| Speedy Builder5 | 01/10/2021 19:29:20 |

| 2878 forum posts 248 photos | If you are a beginner in tool grinding, do pay attention to the tool and its rest. Always keep the free air distance of the wheel as close to the rest as possible which will prevent a hot piece of HSS jamming in between rest and wheel with possible wheel bursting. And of course wear eye protection. Nice set of safety glasses at £30 seem expensive until you loose an eye !! Bob |

| John Reese | 02/10/2021 00:52:53 |

1071 forum posts | Posted by Derek Lane on 01/10/2021 13:44:28:

I have just sharpened my first hss blank I followed This Old Tony on u tube he does his very much like Mr Crispin video, I have just used it to turn some Ali with great results and some great chip breaking rather than long strings.

Congratulations. It is very difficult to create a tool that will break chips in wrought aluminum. |

| John Reese | 02/10/2021 00:58:10 |

1071 forum posts | Something that helps grinding HSS: replace the blue aluminum oxide wheels with friable white aluminum oxide. Many dealers that cater to woodworkers sell the white wheels. |

| Dalboy | 02/10/2021 08:56:32 |

1009 forum posts 305 photos | Posted by John Reese on 02/10/2021 00:52:53:

Posted by Derek Lane on 01/10/2021 13:44:28:

I have just sharpened my first hss blank I followed This Old Tony on u tube he does his very much like Mr Crispin video, I have just used it to turn some Ali with great results and some great chip breaking rather than long strings.

Congratulations. It is very difficult to create a tool that will break chips in wrought aluminum. From what I have learnt I was expecting the long twirls so how I got chips I don't know just luck will try later and see if I can reproduce them. |

| SillyOldDuffer | 02/10/2021 09:30:05 |

| 10668 forum posts 2415 photos | Posted by Steve355 on 01/10/2021 10:19:58: ... 2) when grinding a plane blade, of course the grinding wheel leaves a small amount of curvature. But I just hone this off on the sharpening stone, through several levels of grit and then strop it for a “scary sharp” finish. But on the lathe bit, the area I’d need to hone is much bigger, and I don’t have a nice sharpening jig to keep it perfectly flat against the stone. ...

Steve mentions honing, which I've never done to an HSS cutter intended for use on metal. My logic, which could be wrong, is that metal cutters don't need to be super-sharp because they wedge rather than cut. Note in the picture below, the tool tip isn't in contact with the metal.

The wedging action is taken to the extreme with most carbide inserts which are on the blunt side. A sharp edge is only needed to start a cut or to remove tiny amounts of metal. As a very sharp edge is easily damaged and metal is hard, sharp edges are easily damaged. It's still important that metal cutters have an edge, because being too blunt is a disaster. Never let cutting tools rub! In my mind, metal cutting is rather different to slicing through soft fibrous materials like wood where being razor-sharp is a major advantage. I don't see any value in honing lathe tools. Am I right? Dave

|

| Grindstone Cowboy | 02/10/2021 09:36:15 |

| 1160 forum posts 73 photos | Posted by SillyOldDuffer on 02/10/2021 09:30:05: ....I don't see any value in honing lathe tools. Am I right? Dave

Well, from what little I know, and from personal experience, I've had better results with HSS when it's honed. Rob |

| DiogenesII | 02/10/2021 09:55:36 |

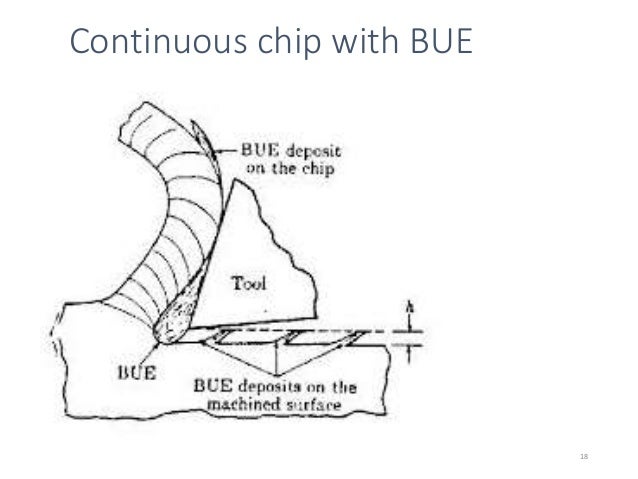

| 859 forum posts 268 photos | Dave, er, isn't that an illustration of undesirable cutting conditions caused by Build-Up Edge deposits? |

| IanT | 02/10/2021 10:13:25 |

| 2147 forum posts 222 photos | Posted by Grindstone Cowboy on 02/10/2021 09:36:15:

Posted by SillyOldDuffer on 02/10/2021 09:30:05: ....I don't see any value in honing lathe tools. Am I right? Dave

Well, from what little I know, and from personal experience, I've had better results with HSS when it's honed. Rob

Like many things, it depends on what you are going to use the tool for and to some extent the size of work and material type. I use a diamond tangential tool for a fair bit on my ferrous work and have found no need to hone, apart to slightly round the tip for longevity. If I intended to use a tool for roughing, I wouldn't bother to hone then either. But on the occasions I need a really sharp tool (fine finish, bronzes, smaller parts) then I certainly do hone and it's very easy and quick to do if you start by using the front of the grinding wheel and already have a concave face. Then you can simply hone the top edge (using the bottom as a guide) - you don't need to hone the entire face, just the cutting edge. Here's a shaper finishing tool that has been honed (the bright edges) the 'grey' area has been ground on the front of the wheel and you can still see the grinding marks (the ground face only looks dull because of the angle I'm holding it at). The same principle can be applied to any single point cutting tool and the smaller the work or finer the finish required - the more often I do it. Regards, IanT |

| thaiguzzi | 02/10/2021 10:25:58 |

704 forum posts 131 photos | If the OP is getting a great price on buying long lengths of HSS (20cms 8" - not unheard of out here), it is very very easy to cut it in half with a 4-5" angle grinder and a 1-1.5mm wide cutting disc fitted. Felt tip marker pen the middle, put it in the vise tight and have at it. 2 x 4" pieces with 4 useable ends. As others have noted, a white wheel in your d/e bench grinder is the way to go, but prior to that, i don't, but you can, use your angle grinder for preliminary shaping. I note that some of the old post WW II ME masters were not averse to using an HSS tool finished on a round wheel, which makes the angles generally easier to finish hone. |

| Dalboy | 02/10/2021 14:53:55 |

1009 forum posts 305 photos | Posted by John Reese on 02/10/2021 00:52:53:

Posted by Derek Lane on 01/10/2021 13:44:28:

I have just sharpened my first hss blank I followed This Old Tony on u tube he does his very much like Mr Crispin video, I have just used it to turn some Ali with great results and some great chip breaking rather than long strings.

Congratulations. It is very difficult to create a tool that will break chips in wrought aluminum. Tried again today all the same settings and feeds but this time got the long strings just lucky the first time it was 6082 ali |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in