First workbench, for an ML7 lathe

| Keith Long | 27/10/2020 15:35:28 |

| 883 forum posts 11 photos | William, both those benches that you linked to above have the same fault - no diagonal bracing. Without that they are liable to start twisting around under even small loads, I wouldn't want a lathe mounted on top if it started to go. I've got a Clarke bench the CWB 1250 in my garage as a workbench with a vice mounted on it - no machinery. That has sheet metal side panels but even so sawing or filing in the vice had the bench moving and twisting. It was fine once it was fastened to the wall! As Howard says above, bolted construction will be fine, and it'll be a lot easier to dismantle for moving that a welded bench. Even buying the steel angle from somewhere like B&Q I think you'll break even on the cost and have a better bench. The top can be made of 12, 16 or 18 mm ply - reasonably easy to cut by hand or get it cut to size by the supplier, the thinner material WILL need support underneath it, but you'll be putting cross beams in under the lathe bolt holes any way - won't you. On bench design I don't think of the top as support for the machine, that has to be part of the bench structure, the top is to stop things falling through and give you a flat area for the other items that you need while using the lathe. I wouldn't worry too much about a drip tray at this stage but if you want one have a look in the garden centres for either plant pot trays or "grow-bag" trays and put that on the bench top with the lathe in the tray. |

| Bizibilder | 27/10/2020 15:37:20 |

173 forum posts 8 photos | A point not yet mentioned is that a bought bench is whatever size the manufacturer provides - At least with a homemade bench you can choose the overall size, especially the height, to make it fit both the space available and to fit your own stature (strangely half of us are above average height and half below!). Edited By Bizibilder on 27/10/2020 15:38:32 |

| duncan webster | 27/10/2020 15:44:14 |

| 5307 forum posts 83 photos | I made one out of 40*40*3 box very similar to Maurice's, but whatever you buy/make make sure it's high enough. I copied the Myford stand height and forever had backache after a protracted session. Lifting it up on 2 off 4" sq timbers got the cross slide up to about navel height, much better |

| Bazyle | 27/10/2020 15:51:52 |

6956 forum posts 229 photos | It is hard for us older guys to judge value for money sometimes as we remember when things were quarter the price forgetting our payslip was even smaller, so the linked bench looks just bad value. Have you tried ebay for Dexion angle, not the newer tin can dexion shelves, the old 'big meccano' type. |

| William Ayerst | 27/10/2020 16:06:58 |

264 forum posts | Gosh there just isn't a simple solution, is there? Thank you for the pointers on why I should specifically avoid that Clarke bench. I had not thought about bolting together a bench out of steel angle, that may be a good bet.This kind of thing? (auction site item 301986013602) ? Are corners dealt with by diagonal braces, or the 'corner pieces' I see sold on the site also (they look a bit cheap!) I see that Myford are selling a complete stand with risers, also. Edited By William Ayerst on 27/10/2020 16:07:28 |

| SillyOldDuffer | 27/10/2020 17:34:52 |

| 10668 forum posts 2415 photos | Posted by William Ayerst on 27/10/2020 16:06:58:

Gosh there just isn't a simple solution, is there? ...

How wonderful does the stand under an 85kg lathe need to be? At a pinch a kitchen table would do, as would a kitchen worktop with ordinary units underneath. Whatever is used, a bench is strong enough if you can stand on it. So why all the fuss? It's because lathes work better when they're rigidly supported - no swaying side to side, bending, or vibration please. The Myford is a rather bendy lathe and a virtue is made of bending the bed to eliminate bed-twist, by levelling. As it's tricky to level anything on a bench that moves about, best to stiffen the bench up. Older lathes were often mounted on massive cast-iron stands rag-bolted to the floor, later machines on carefully braced steel cabinets. So the idea benches should be as solid as possible isn't daft, but I feel there's no need to obsess about it. Many a Myford has done good work despite being balanced on a wobbly bench in a flimsy shed. MachineMart may not be my first choice either but they're convenient and stuff can often be inspected before purchase. The Clarke bench William identified in his opening post is a reasonable solution, especially when moving house later is a consideration! Would benefit from a bit of reinforcing though. I'd stiffen the top with some kitchen worktop. Doesn't need to strong, just good enough to spread the pressure so the tin underneath doesn't dimple under the lathe's feet. More seriously, the absence of struts between the legs makes the bench likely to wobble, but that can be fixed simply by bolting plywood panels or diagonals between the sides and rear. Screwing the back of the bench to a wall would be a substantial improvement. Beware of councils of perfection. We're all brilliant at spending other people's money!

Dave |

| Maurice Taylor | 27/10/2020 18:01:17 |

| 275 forum posts 39 photos |

Maurice

|

| Bazyle | 27/10/2020 18:35:48 |

6956 forum posts 229 photos | Posted by William Ayerst on 27/10/2020 16:06:58:

.This kind of thing? (auction site item 301986013602) ? yes, enough there for a bench 6ft long by 3 high and 2 deep. For diabonal bracing use sheets of ply at sides and back. |

| William Ayerst | 28/10/2020 10:33:14 |

264 forum posts | Thank you all so much for your help, - I think I'm just going to buy a Myford stand or have someone weld me up something out of steel box section - this is too much bloody aggrivation! Edited By William Ayerst on 28/10/2020 11:20:30 |

| not done it yet | 28/10/2020 11:41:01 |

| 7517 forum posts 20 photos | this is too much bloody aggrivation! If that is too much aggravation, just wait until you need to decide what type of toolholding you need. Finger collets, Weldon, Clarkson type or ER - to name a few.🙂 Then whether to go for ER 11, 16, 20, 25 or 32! Remember the old maxim - buy cheap, buy twice. Or a newer one.... Only buy direct from China if you can afford to throw it away

————————————————————————————————————————————————— I used to be undecided, but now I’m not so sure. |

| Baz | 28/10/2020 13:56:36 |

| 1033 forum posts 2 photos | I must agree with Duncan regarding lathe height, I am of average height, five foot nine tall and every lathe I have worked on is in my opinion too low, the worst for me being the Colchester Bantam, which I have now raised four inches and perhaps needs to go up another two inches to be ideal. The Myford for me needs to be raised four inches to make it comfortable to stand at for a full days machining. |

| Howard Lewis | 28/10/2020 21:04:21 |

| 7227 forum posts 21 photos | If you buy angle iron (40 x 40 ate least 3, you can make your bench to a size and height that suits you. The diagonal braces can be 40 x 3. If bolted together, can easily be dismantled for moving house. Material cost will probably be less than that of one commercially available. And you can build in as many shelves or drawers, of the size that you think will be most useful. Commercially available items always include something that you regard as less than ideal. Having anything bespoke made will be expensive. If you have time on your hands, the labour cost is Zero, unless you hire in help. A substantial top, with ametal upper surface will be almost wear proof. Visits to your local steel stockholder and somewhere like B&Q could provide you with a better bench than could be bought. And when the lathe is on the bench, you level the lathe on the bench to remove twist, not by adjusting the bench. I tried that once, and found that the benchwork was so rigid that lifting one corner lifted the whole end! You can make suitable risers to level the lathe from box section, studding, and a number of nuts, even 25 x 25 RHS will do. Howard. |

| William Ayerst | 29/10/2020 09:09:16 |

264 forum posts | Friend of mine is going to build me a bench out of welded steel box section to my spec, i.e. size/height with mounting holes for the lathe on crossmembers and a galvanised steel drip tray for £240 delivered in primer. Much simpler! |

| SillyOldDuffer | 29/10/2020 10:39:34 |

| 10668 forum posts 2415 photos | Posted by William Ayerst on 29/10/2020 09:09:16:

Friend of mine is going to build me a bench out of welded steel box section to my spec, i.e. size/height with mounting holes for the lathe on crossmembers and a galvanised steel drip tray for £240 delivered in primer. Much simpler! Can you share the design William? Designing a stand to take the weight on an ML7 is trivially easy, the devil is in achieving rigidity and stability. If you're going to spend £240 on making a bench, it makes sense to confirm the design is fit for purpose. I'm wondering if someone who has to ask about benches is well-placed to design one from scratch? Benches aren't rocket science, but people tend to focus on weight without worrying enough about top heavy lathes on a tall narrow stand being dangerously easy to topple over, or the possibility legs might scissor, or the need to stop the top deflecting whilst minimising shake and vibration. Here's a Victorian treadle lathe. Flimsy stand, only suitable for low power, slow speed and carbon-steel tools. Not very stressed and the bed girder is part of the structure. OK in it's day, but times change.

The treadle design isn't up to a motor and HSS cutters; the whole thing vibrates when pushed hard. The next generation of lathes went for heavy cast-iron bases:

Although cast-iron is cheap and effective as a machine tool material, it makes the tool heavy and awkward to transport. And although cast-iron looks strong, it's weak in tension and brittle. Easily damaged. Next improvement was towards strength and rigidity achieved by clever design rather than simply by pouring more cast-iron. Steel frames, box structures, welding etc. Done properly, they are stronger, cheaper and more robust than cast-iron. The change led to modern lathes (designed after about 1940) to be slimmed down so the lathe bed isn't part of the weight bearing structure, as taken to an extreme by the arch in the example above. These lathes are intended to sit on solid stands rather than be part of it, reducing cost and improving accuracy, This Colchester sits on boxes.

Big lathes come up to operator height fairly naturally with a low centre of gravity. Smaller lathes have to be lifted up on a stand to about elbow height, resulting in a high centre of gravity, making them prone to wobble and toppling. Worth confirming the proposed stand ticks the right boxes before building it! Dave

|

| Maurice Taylor | 29/10/2020 13:32:01 |

| 275 forum posts 39 photos | Hi William, Your design sounds very similar to mine.(Photo earlier in the thread). It is made from 50 x 50 x3mm square tube, It does not have diagonals and is very strong.The extended feet make it very stable.It is based on an MEW articlle from a few years ago.The base plate under the lathe is only 18guage steel ,the lathe is bolted to the 2 cross members. I think your price quoted is good. Unfortunenately there some complications engineers on the forum that make a simple job look daunting and difficult without offering any useful help and often have a downer on things other people are doing. Maurice |

| Dave Halford | 29/10/2020 13:40:51 |

| 2536 forum posts 24 photos | Posted by Maurice Taylor on 29/10/2020 13:32:01:

Hi William, Your design sounds very similar to mine.(Photo earlier in the thread). It is made from 50 x 50 x3mm square tube, It does not have diagonals and is very strong.The extended feet make it very stable.It is based on an MEW articlle from a few years ago.The base plate under the lathe is only 18guage steel ,the lathe is bolted to the 2 cross members. I think your price quoted is good. Unfortunenately there some complications engineers on the forum that make a simple job look daunting and difficult without offering any useful help and often have a downer on things other people are doing. Maurice

No No No wait, what about the earthquake risk? Have you considered floats in case there's a flood? |

| William Ayerst | 29/10/2020 17:46:43 |

264 forum posts | HA! The guy who is building it for me is a good friend and has been welding and fabricating for almost 20 years doing this kind of thing so I trust him - I've supplied the lathe fixing dimensions and the risers/drip tray/etc/etc. and I'm going to leave the rest to his knowledge and wisdom, certainly more than mine (given that as you said, I had to ask for help). When it arrives, I'll be sure to post pictures - thank you!

Cheers, |

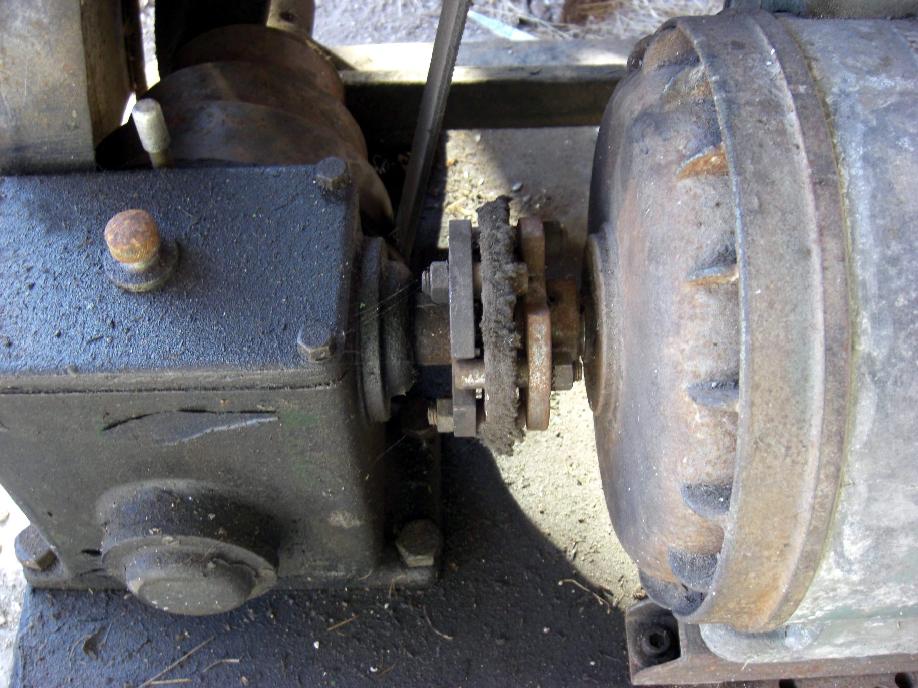

| William Ayerst | 08/11/2020 09:15:11 |

264 forum posts | Hi all, Just an update - here is the bench in progress - the holes to bolt the bed down and that for drain hole haven't been done yet in these photos, but they and some riser blocks are also ready.

|

| Michael Gilligan | 08/11/2020 09:54:37 |

23121 forum posts 1360 photos | That’s looking good, William ... but I must mention that it could be considerably stiffened by adding triangulation at all convenient locations. These could be welded-in struts, or tension wires, or firmly-fixed panels. Happy to discuss, if you wish ... but you should easily find guidance by web-searching for ‘triangulation’ MichaelG. . Edit: This seems a very good place to start: ... https://dsportmag.com/the-tech/chassis-tuning-torsional-rigidity/ Edited By Michael Gilligan on 08/11/2020 09:59:41 |

| William Ayerst | 08/11/2020 10:08:40 |

264 forum posts | Good thought Michael! Initlally this lathe isn't going to be doing anything very strenuous at all - smaller work in brass and aluminium, but I guess it would be fairly simple to drill some holes through the box section for bolt fixings for 'X' straps on the sides and back? |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in