Member postings for JasonB

Here is a list of all the postings JasonB has made in our forums. Click on a thread name to jump to the thread.

| Thread: Milling on a mini lathe |

| 20/09/2023 07:19:30 |

Although NDIY says much good work has been done with just a lathe it does depend on the particular lathe. A Myford particularly with a long cross slide that has a good range of tee slots makes fitting work directly to the cross slide or mounting a vertical slide rigidly quiet easy. and is what you will find in the older books. Myford also has a gap allowing a larger faceplate to be swung so more work can be turned than milled. The average 7 x * Mini-lathe does not have a slotted cross slide so you will either need to make one (as Editor Neil did) or be limited to milling only small parts that can be held in a vertical slide. Even then some of the mini-lathe slides are anything but rigid so you will be very limited in the amount of metal that can be removed. This for example is quite a poor option, this a bit better Then there is also the question of how best to put on a cut, a myford with a handwheel on the end of it's leadscrew makes it fairly easy to advance the tool using the handwheel graduations, Mini-lathe you would need to set up a plunger dial gauge and make do with the front carriage wheel to advance the work. Add to the cost of the vertical slide and a Dial gauge a small vice to fit the vertical slide, a means to hold milling cutters be that a range of MT finger collets, sidelock holders or an ER type chuck and you soon start to get to a point where waiting a while until a stand alone small mill is not going to cost a whole lot more. |

| Thread: Searching forums and albums |

| 20/09/2023 07:03:49 |

Some are 60 depending on the model I believe, if not stick a change wheel on the far end of the spindle. Not sure about wrinkles, more like hills and valleys |

| Thread: Broken toolmakers clamp. |

| 20/09/2023 07:01:14 |

The easiest option would be to use rectangular stock. So instead of 3/8" or 10mm square use 3/8" x 1/2" or 10 x 12. Put the holes through the shorter distance then there will be more metal at the sides of the holes for added strength. Then to save the jaws being too wide taper on three sides not just the outer one. I've snapped a couple of cheap no brand ones. |

| Thread: Tap compatability |

| 19/09/2023 19:34:50 |

Below 1/4" UNF and UNC use a number system rather than the nominal diameter so yes #10-32 UNF is their nearest to 3/16" dia and you can happily thread 3/16" rod to that size. If you happen to have 2BA that will also do for 3/16"

Edited By JasonB on 19/09/2023 19:37:17 |

| Thread: NALON VIPER 2.5 CC DIESEL |

| 19/09/2023 14:53:41 |

I think the 0.005 is just a very slight easing of the inner edge where the angled cut meets the top of the crankcase. If you really enlarge the PDF you can tell the difference between construction lines and dimension lines It is easier with a pressed in pin but can be done with a long slender tool, I would use something with a more rounded end so you get a fillet in the internal corners and that also makes it easier to move the tool front to back cutting in both directions. The alternative is to hold the crankshaft vertically on a rotary table and mill the recess, again probably I'd use a cutter with 1mm corner radius 6mm OA dia should fit easy enough Might need to grind down a cutter's sides and plunge with the cutting ends, Edited By JasonB on 19/09/2023 14:54:45 Edited By JasonB on 19/09/2023 15:05:31 |

| Thread: 1/3rd Scale "Ball Hopper" Monitor Build |

| 19/09/2023 11:03:30 |

Send me a private message with your e-mail a sthe files are a bit big to post here, you can do that by clicking "message member" at the bottom of this reply. I'll also copy yhe details from the larger engine which has a separate venturi insert with double taper that went into the inlet hole which you could possibly add to the smaller engine. Also make sure the non return valve on top of the fuel tank has not picked up so much from the tank and is allowing tehfuel to drain back when it is missing between hits |

| 19/09/2023 10:04:08 |

Ah that is the smaller VJ (vertical Jack) Monitor that you have there not the larger one on HMEM and that I built. Luckily I also have the VJ and will dig out the drawing for you a bit later. It is a bit more basic than the larger engine but so was the original engine.

Edited By JasonB on 19/09/2023 10:10:58 |

| Thread: Trying to identify a bird-feeder thread. |

| 19/09/2023 09:57:46 |

Good idea to make it a pull out then it will be easy to throw in the bin |

| 19/09/2023 07:06:56 |

Ah but you also need to consider the commercially sold poles which tend to be supplied in reasonably short lengths for easy postage and screw together often with threaded connectors and you can also buy extension poles. Keeping these to both a standard thread and also one that works with metal tube makes it better to use the same thread for the bird feeder at the top of the pole too. |

| Thread: Heat Resistance - Wood & Wood Products |

| 19/09/2023 06:58:14 |

Typical traction engines don't have anything over the fire box or top of the boiler above the firebox. Insulation is only on the round horizontal part of the boiler from throat plate to smokebox. So your waggon boiler would likely have been similar. maybe the top half of the vertical part would be insulated too much like you see on a wood clad vertical boiler where the wood does not extend down to the firebox. If it is to make the boiler look the right size then just use metal around the vertical part of your boiler and wood/insulation below the cleading for the horizontal part. AOne of the softer aluminium sheets would be quite easy to form over a turned ply or MDF former. If made to a Z section it would be fairly simple to clamp it to the boiler and leave a flange for fixing screws to take the outer cleading.

Edited By JasonB on 19/09/2023 07:00:04 |

| Thread: Measuring instrument storage. |

| 18/09/2023 17:03:22 |

Not had any problems |

| 18/09/2023 16:47:52 |

Does it have to be a chest of that style or would a set of Bisley draws do for you, that is what I use with some home fitted divisions |

| Thread: Advice Wanted - On obtaining help... |

| 18/09/2023 16:43:20 |

If you go for a backplate fitting chuck then once the thread has been cut in the backplate which could be done with drill press and tap then the remaining machining is done in situe so does not need a chuck to hold the backplate. A backplate mount chuck also needs no modification. May lessen your chuck choice a bit in the smaller sizes which tend to more commonly come with a threaded body. What diameter chuck were you looking to fit? |

| 18/09/2023 10:55:02 |

I'd be inclined to have the bore a little over 1/4" so you can pass that diameter stock through it. 6.5mm would do and also avois a step where the small end of the taper meets the bore as MT0 is just over 1/4". You may also want to condider specifying a finish particularly for the bearing surfaces which may be better off ground than turned. Does the Flexispeed have bearing shells or does the spindle run directly in the Cast iron, if in the iron than again a little over 1/2" could be useful if the bearing surfaces have become worn that would allow them to be fitted to the new oversize spindle. |

| Thread: Warco Major milling machine |

| 18/09/2023 10:09:56 |

All the hobby mills will cut steel, what you need to be asking is will it remove metal at the rate I want? If you are after industrial rates of metal removal you may want to look for something more substantial. As said the round column machines have become less popular with the advent of many choices of dovetailed column machines that are now available. |

| Thread: Heat Resistance - Wood & Wood Products |

| 18/09/2023 07:57:51 |

The insulation tends to go between the crinolines. Not really used on the originals as they were fully wood insulated but most models use a crinoline spacers to support the outer sheet cleading and modern Kaowool or similar insulation between For the firebox I'd be looking at metal for any crinolines. |

| Thread: Myford Ml7 Technical Drawings |

| 18/09/2023 07:50:09 |

I think most people making their own patterns would print in somnething like PLA which is the usual basic filament material and then after some surface prep use that as the pattern. One or two may CNC cut the pattern. You would ideally want a STL file for printing and STP or STEP if CNC cutting with suitable allowance for shrinkage of the chosen metal, machining allowances added to all faces to be machined including draft angle, core prints added as required and then suitable core box drawings/files to form the cores in. If the part needed to be split in half then you would want two files and need to include pins/sockets to locate the two halves together. Then there would be a separate machining drawing required. |

| Thread: Heat Resistance - Wood & Wood Products |

| 18/09/2023 06:58:16 |

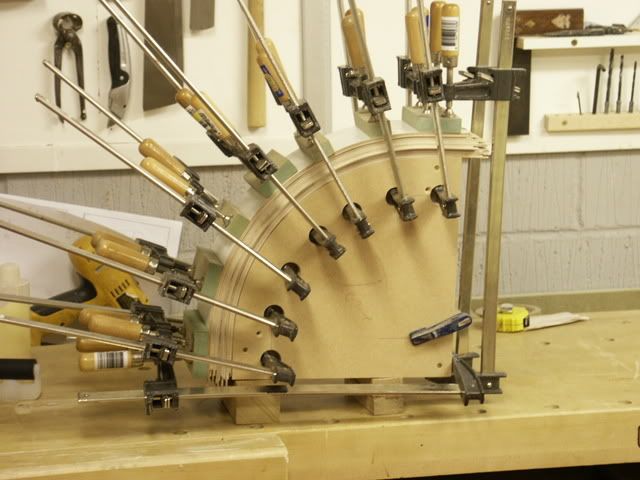

I have done the spacing rings using thin "aircraft" ply cut into strips and then laminated several of these strips over aformer. Once set the adhesive will stop the ply springing back to flat. Not got aphoto but this is the sort of thing where I have been laminating furniture. You could just use apiece of your existing tube, laminate say 3/4 of the way round and then you can cut back the ends to make the rings from two halves with a simple halving joint. I doubt anything wooden will last around the Firebox, OK for the horizontal part of the boiler

I would not us eMDF even exterior grade for this though I have done it in the past for stationary engines as mine just get run on air.

Edited By JasonB on 18/09/2023 07:01:52 Edited By JasonB on 18/09/2023 07:31:58 |

| Thread: Macc Models |

| 17/09/2023 18:54:41 |

| Thread: Play in new arbour for mill |

| 17/09/2023 18:23:26 |

The plunge type are not ideal for measuring small amounts of run out, a lever DTI rather than your dial gauge would be better. Not good to run at too fast a speed but not sure what your lowest is. I'd like to see less than 0.09mm The spindle bearings may just need some adjustment if you think you can feel movement, I assume they are taper roller type. This is almost a bit fast but the problem with turning by hand if there is bearing play is you can be moving the spindle with uneven hand pressure. This is the type of runout you should be looking for, one of those divisions is the same as one of yours so about 0.003mm on the arbor or spindle, drill in the chuck won't be as good Edited By JasonB on 17/09/2023 18:29:52 |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in