Member postings for Jonathan Mead

Here is a list of all the postings Jonathan Mead has made in our forums. Click on a thread name to jump to the thread.

| Thread: UK Drills 10% Off |

| 26/03/2018 11:18:30 |

UKdrills.com have got a special deal on for Easter, with 10% off everything ordered between now and Thursday. Use the code easter at checkout. I've used them in the past and they have some reasonable stuff for good prices. |

| Thread: Warco WM250 Setup Progress |

| 27/02/2018 21:10:26 |

Following on from my previous thread about strip down for cleaning, I have made good progress with the setup of the new lathe. Whilst still on the pallet i fitted the Z axis DRO at the back of the bed below the saddle and assembled the stand that I bought with the lathe. With help from my son, the lathe was lifted onto the stand and bolted down, and I could get on with fitting the X and Z1 scales on the DRO system. I then spent a good few hours just turning different materials and getting a feel for what to me is a much bigger machine. Feeling confident, I decided to turn the 11mm shaft for my Hemingway power hacksaw build, which uses ½ inch round bar as the starting point. I had a live centre in the tailstock as the shaft is 5⅛ inches long and I thought it was going well until I measured the diameter at each end. I had 10.98mm near the headstock and 11.24mm at the tailstock end! Today, I set about taking some measurements using the ground test bar that I bought from Warco with the lathe. I set a lever dial indicator up on the cross slide and measured near the headstock and at the end in both lateral and vertical planes:- Zeroed at the headstock for lateral deflection

Lateral deflection 0.04mm

Zeroed at the headstock for vertical deflection

Vertical deflection at end 0.07mm

Whilst I was doing these measurements, I noticed that there was a blemish on the spindle face, almost like a small weld spatter that was securely attached and needed removing with a riffler file and some emery. This must have been affecting the alignment of the chuck:-

Finally, I did a test turn as recommended in other threads on this site. I didn't have a piece of steel 25mm round bar so used aluminium. Chuck end diameter

Far end diameter

So the difference between the two measurements is 0.034mm. I realise that I need to shim the bed to try and reduce the variation, but am unsure how to do this on the WM250, as unlike an ML7, the bed has one bolt at the tailstock end and two bolts on the long centreline of the bed under the headstock. Any help/ advice would be welcome. |

| Thread: Strip Down to Clean New Warco 250V |

| 14/02/2018 16:41:04 |

I received my new Warco WM250V last Friday and have been slowly getting things together in the workshop ahead of installing it. I'm having to do a lot of sorting out and moving around, but have also unpacked the crate and at least verified that the motor and speed control work. I'm going to fit a DRO system and thought that it would make sense to fit the scale for the Z axis before installing the lathe onto the stand, as accessing the rear of the bed will be more difficult afterwards.

I also need to clean all the shipping grease off the machine and was wondering how far to strip down the saddle and cross slide. How easy is it to disengage the saddle from the lead screw and remove it from the bed? |

| Thread: A quality aluminium alloy (for Myford castings) PRIMER? |

| 13/02/2018 09:26:27 |

UPol Acid 8 etch primer or Halfords own brand equivalent are good for aluminium and brass. It goes without saying that getting the surface completely clean and degreased is essential for good results.

|

| Thread: selling Sweet pea part build |

| 05/02/2018 22:03:04 |

Michelle, there is a dedicated Sweet Pea owners group on Facebook. There are part built Sweet Peas advertised for sale on a fairly regular basis on the group. |

| Thread: Hemingway Westbury Hacksaw |

| 18/01/2018 21:56:18 |

The photo shows everything that comes from Hemingway - it is very complete and includes the motor and worm drive gearbox. The castings are all aluminium alloy, so hopefully will be cleaner to machine than cast iron. Mark, I saw your post - obviously Hemingway hacksaws are like London buses

|

| Thread: Views on the Warco WM14 with 3xDRO |

| 18/01/2018 21:49:06 |

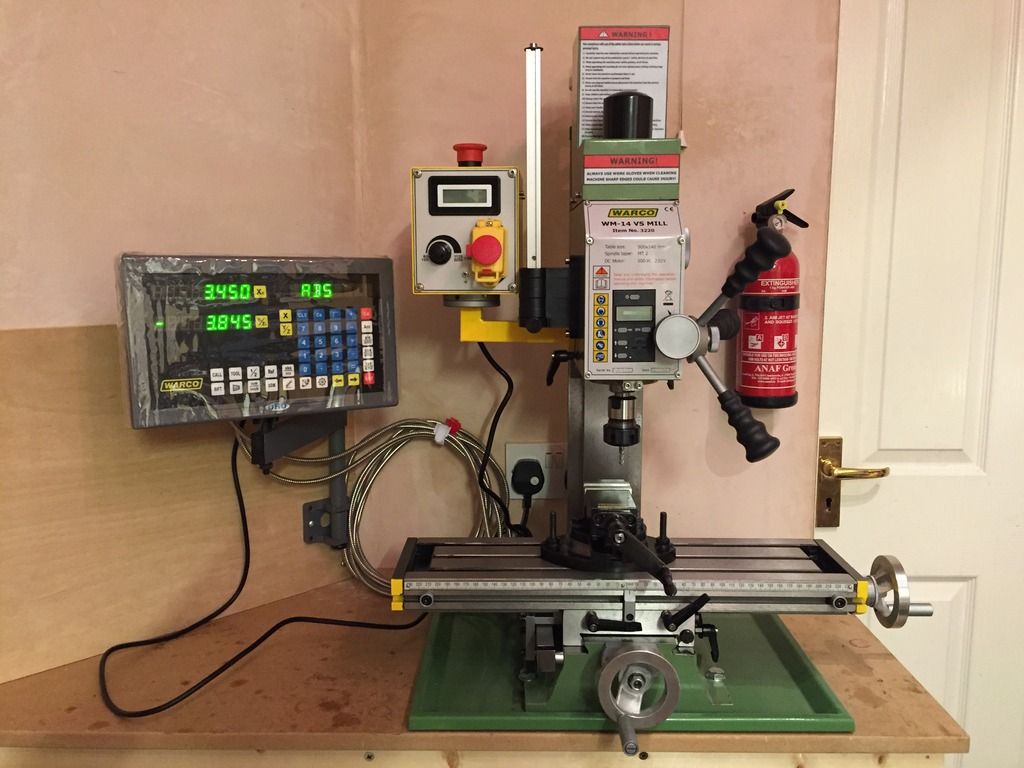

I bought a WM14 last year and fitted the Warco DRO system on the X and Y axis. I've been very pleased with the performance of the mill and DRO - the PCD and chain drilling functions have been extremely useful. The WM14 has a captive drawbar making changing arbours etc very easy. I bought an ER25 collet set and MT2 chuck, and use this most of the time, so R8 versus MT2 isn't really an issue.

|

| Thread: Hemingway Westbury Hacksaw |

| 16/01/2018 17:02:05 |

I can't seem to edit my original post, so here is the original photo of the kit parts, now uploaded onto my albums on this site. I have completed the first machining on the drive wheel so far, but have been away on holiday for the last 2 weeks. More to follow.

|

| 29/12/2017 10:06:55 |

I ordered the kit in November, and after a few weeks wait for the castings, it arrived in mid-December. I plan to start this in the New Year, but in the meantime here is a picture of the kit unpacked for contents checking. The drawings and instructions are very good, and I'm looking forward to getting started.

Edited By Jonathan Mead on 29/12/2017 10:08:58 |

| Thread: Anyone Got a Warco WM240B? |

| 16/11/2016 10:15:06 |

I'm thinking of getting a slightly larger lathe and the Warco 240B has caught my eye - simple machine without all of the potential problems that come with electronic speed control systems and capable of a good speed range from 125RPM upwards. Does anyone on the forum have one, and if so, what are their experiences?

|

| Thread: Fitting dro to warco WM14 Mill |

| 30/09/2016 21:27:34 |

Mick, send me a message if you have any questions - I'm happy to help. |

| Thread: Micro angle grinder? |

| 19/08/2016 21:57:02 |

Bosch do a 10.8V cordless angle grinder which has a 76mm dia disc. It is quite expensive at around £90 plus a battery. |

| Thread: How on earth do they do it? |

| 14/08/2016 17:05:04 |

I've thoroughly enjoyed watching the Olympics so far and am proud of the dedicated athletes who have been so successful. Team Great Britain has already delivered performances that we should recognise and celebrate, and I'm sure that there is more to come. Like Sam, I sail and have enjoyed the coverage on the dedicated channel. With the onboard cameras and the computer graphics, sailing on TV has come a long way. The lottery money has helped, but commercial sponsorship, money injected by government into centres of excellence such as Bath University have also helped to improve our performance on the international stage. |

| Thread: Has anybody have harley/indian (from50's)like v-engine plans? |

| 07/08/2016 13:43:30 |

Isn't the Hoglet a small V twin engine similar to a Harley? A google search for Hoglet model engine will being up links, photos and videos.

|

| Thread: Hemingway Compact Powered Hacksaw |

| 26/07/2016 10:49:57 |

Thanks for all the replies. Interesting that nobody has actually built the Hemingway kit to date. Two things attract me to the powered hacksaw - the more compact footprint for my small workshop and the one that my friend has. His is the Blackgates Engineering one, but they don't list it in their current catalogue. It would be cheaper to buy than the Hemingway kit but is pretty much a set of castings and you have to source the motor and other parts yourself. I'll be going to the Bristol show in a couple of weeks time and will have a look at the bandsaws on the Warco stand and talk to Blackgates about casting availability. |

| 22/07/2016 17:47:32 |

Having got the mill and lathe set up, I think the next tool that would be useful is some kind of powered saw, either a bandsaw or a powered hacksaw. The latter is attractive as I think it will have a smaller footprint in the workshop but the only small one that seems to be commercially available is the Axminster at over £600. The Hemingway kit is a bit more affordable at under £400, but it is hard to tell from the website how much of a job it is to machine and assemble the kit. Does anyone on the forum have any experience of building one? Is it fairly straightforward, or are there lots of complex machining operations needed? Thanks in advance for any help that you can give. |

| Thread: Fitting Warco Glass DRO System to WM14 Mill |

| 20/07/2016 19:43:05 |

Thanks Jon. I've now refitted the rubber guard, and it seems to be working OK. I've used the same fixing point as the slider and mounted the rubber on the outside. Although not ideal it seems to be working OK and keeps the leadscrew clear of swarf. Overall I'm very pleased with the quality and performance of this system so far, but obviously need to see how reliable they prove to be over the coming months and years. |

| 18/07/2016 15:58:10 |

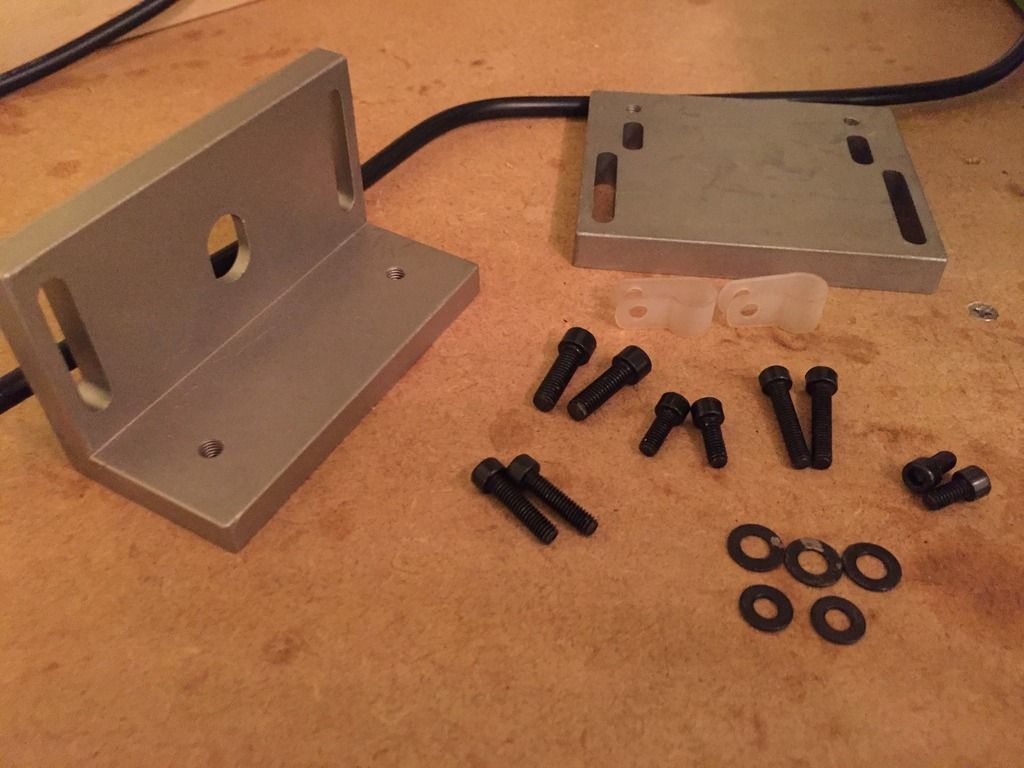

I bought a WM14 mill at the recent Warco open day and took the opportunity to play with the display machine in the showroom that was fitted with the 'new' glass DRO system. The system seemed well made and so I ordered a 2 axis system to go with the new mill. Unfortunately the scales were out of stock for a while so I took the chance to get to know my new mill before summoning up the courage to drill holes in it to fit the DRO system. However once the scales arrived it was time to get on with it and get the job done. The X axis was quite straightforward and fitted well onto the back of the table, but the Y axis caused a bit of head scratching but I got there in the end. The installation of the Y axis system was helped greatly by the fitting kit that comes with each scale that includes a flat and angled bracket nicely cast in aluminium and a good selection of M4 and M5 socket head screws. Using the mill to machine these to size was quite simple once I had worked out what needed to fit where. Here are some photos of the finished job.

Y axis scale showing cut down bracket and plate to transfer motion to the slider.

X axis scale at the back of the table. The only issue that still needs sorting is how to fix the rubber strip back in place in a way that doesn't channel swarf towards the scale.

Completed system working nicely. I wish the leads were more easily shortened but spitting a connector apart showed that they were very nicely soldered with the screened cables properly grounded to the connector body and so I decided to leave well alone.

The accessory kit that comes with each scale. This ended up being spare as it wasn't needed for the X scale. |

| Thread: Which mini mill? |

| 02/05/2016 11:23:48 |

I have recently been through this process, and ended up buying a Warco WM14. For me this was the best balance of size, features and price. I looked very hard at the Sieg/ Axminster SX-2 mills, but decided that a machine with a leadscrew adjustment for the head and a separate quill was the better option for me. I'm very pleased with my choice so far and the WM14 is well suited for the type of work that I'm doing. The captive drawbar was an unexpected bonus. I would have liked a brushless motor machine, but as with all things, some compromise was needed. |

| Thread: Silicone sealant WITHOUT acetic acid |

| 04/03/2016 23:01:48 |

Silicone sealants are either 'acetoxy cure' or 'neutral cure'. These are the key phrases to look out for when purchasing. To avoid the corrosion problems, use a neutral cure sealant. Screwfix and Toolstation sell neutral cure sealants. |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in