Bridgeport spindle problem

| Richard Clark 1 | 12/05/2014 20:31:37 |

| 48 forum posts 1 photos | Hi, I think I have a problem with the spindle bearings in my Bridgeport, I have noticed that the spindle moves up about 6-8 thou axially, definately the spindle not the quill. Can anyone let me know if its possible to inspect the spindle bearings and how this is done I read on the internet about a guy tapping out the spindle assembly from the quill but that was on a step pulley head and I have a varispeed head. The varispeed head is super quiet so i am guessing that things have been replaced over the years but i would like to investigate the spindle problem. Could it be a loose nut or faulty bearings they seem quite enough no grinding sounds? Any info or tips would be appreaciated. Regards Richard |

| John Stevenson | 12/05/2014 20:53:56 |

5068 forum posts 3 photos | Drop the quill down a couple of inches. At the back about an inch up is a small grub screw, remove this, then check it's the only one in the hole. Bridgeports have a nasty habit of fitting two screws in the same hole to lock them but I'm sure this one is that shallow it can only hold one. Then unscrew the ring at the bottom, genuine Bridgeports use LH thread, some clones RH the better Taiwanese close LH again.

Once the ring is removed the spindle will cone out of the quill by tapping down. Sometimes if the bottom ring hasn't been fully tightened wear can take place giving more plat and often just tightening up will suffice to remove this.

There are a pair of matched Class 7 ABEC angular contact bearing at the bottom and a standard deep groove ball race at the top.

The angular contact bearings have spacers in between the inner and outer to set preload, the should show no signs of spinning or wear on the faces.

Don't know where you are but if you get stuck for service or repairs try these people.

Good lads, do a cracking job, know what they are doing and carry a good range of spares. |

| daveb | 12/05/2014 21:04:19 |

| 631 forum posts 14 photos | Try tightening the nose cap. If you move the quill down a little, there is a locking screw at the back, about 1/2" up from the nose cap, it should not be very tight as it's easy to distort the quill, makes the last 1/2" of up travel very tight. Sometimes it's not tight enough and allows the spindle nose cap to turn slightly. Once you have loosened the locking screw, tighten the cap(normal R/H thread) and then the locking screw. If you need to dismantle, first turn head upside down and support with table, remove 3 nuts, then lower table, upper head unit comes off in 1 piece. Lower head and spindle same for J and 2J2. |

| _Paul_ | 12/05/2014 21:44:45 |

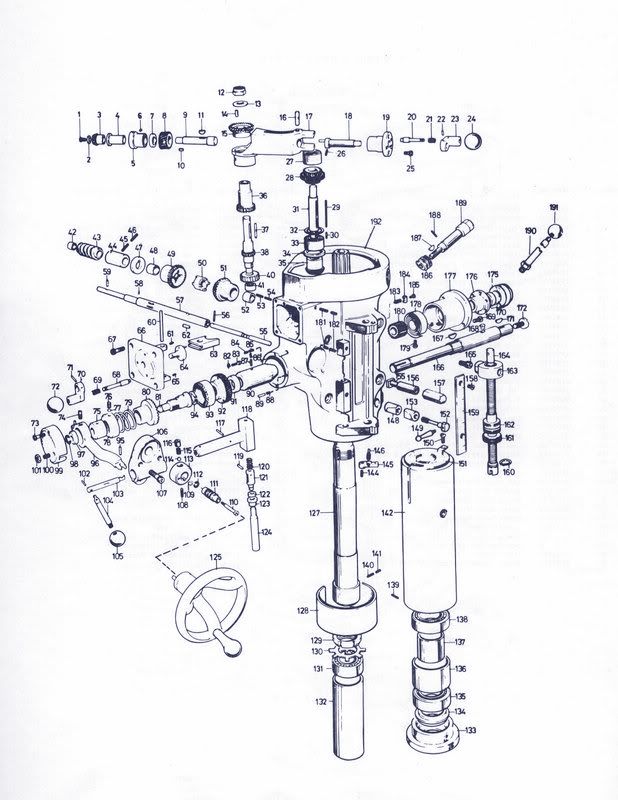

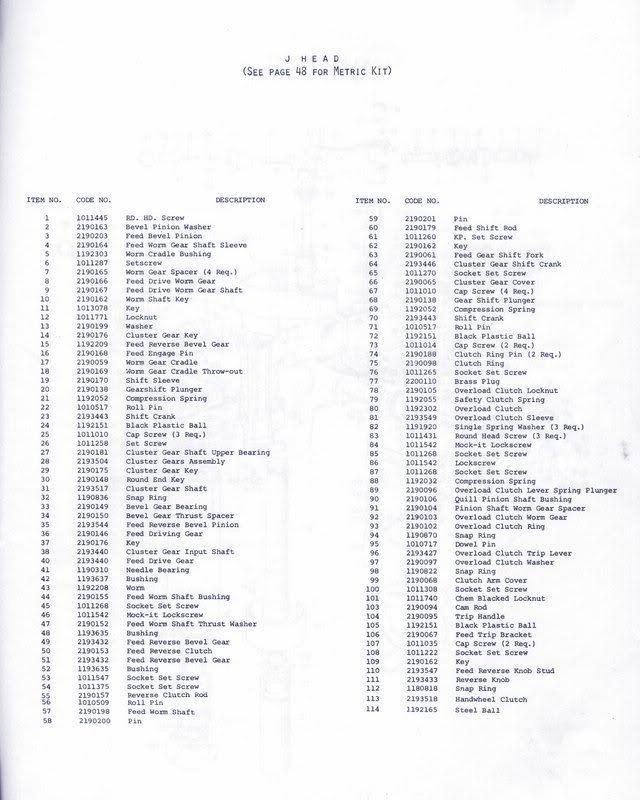

543 forum posts 31 photos | As John says but some Bridgeports have a slightly longer screw (165) holding the quill stop knob on (163), if the spindle drops a short distance then stops solid it's probably caught on this, no great shakes it just means taking out the quill stop screw (164) and the stop, put a bit of timber underneath it as it can come out quick.

Paul |

| Richard Clark 1 | 12/05/2014 22:22:55 |

| 48 forum posts 1 photos | WOW, This forum really is the best I didnt expect the replies that quick thats great, I thought it may be possible to remove the spindle but its better to ask than bugger something up. The only problem is 1 saying its a left hand thread and 1 right hand thread?. like john says different machines ie import etc. I have a Adcock and shipley Bridgeport with 2J head I think manufatured around 1974. If you could just confirm if its LH or RH I would be grateful, as I will make a suitable pin spanner for it as I tried a rubber strap wrench and its too tight for that ( I have removed the little grub screw) and yes thanks John I did look to see if there was 2 fitted but luckily only one in there. Its great to have so much help on hand . Thankyou all Richard.. |

| John Stevenson | 12/05/2014 23:19:01 |

5068 forum posts 3 photos | That got me wondering as well, I can ring Nick at Apex tomorrow and ask if it's RH or LH. If it wasn't as late as this I'd text him. Silly enough I had the nut of mine the other week to remove a bent locating pin. My own fault. Note to self " Remember to fully tighten drawbar before taking 1" cuts"

Mine is a Taiwanese clone, the largest of the ones that Warco does, the WM40 and I'm sure it was left hand. Which is the same as what Nick told me the Bridgy's were but you are now making me doubt my own mind |

| _Paul_ | 13/05/2014 00:21:51 |

543 forum posts 31 photos | IIRC The last BR2J I took apart had a 1988 plate on the base and the nose piece was r/h thread (Singapore manufactured head). Make your pin spanner a really good fit lock the quill run the knee up with a bit of timber on the table and push the spanner into good contact with the cap before letting fly with the mallet. |

| John Stevenson | 13/05/2014 14:37:13 |

5068 forum posts 3 photos | Just had a text back from Nick Wood over at Apex and he says all the Bridgy's, genuine and the A&S ones are LH. Some clones are RH but there is no way of knowing.

Thank Christ the pills are still working |

| Richard Clark 1 | 14/05/2014 20:29:41 |

| 48 forum posts 1 photos | Thanks for the info on that john its a bad thing not to have mentioned it in the manual I will make the pin spanner at the weekend thanks john |

| Richard Clark 1 | 25/05/2014 20:58:25 |

| 48 forum posts 1 photos | Hi to all, Just an update, I made the pin spanner to undo the Bridgeport nose piece, it was on there very tight so plenty of WD40 and keep working the nose piece got it freed off it took about 2 hours of gentle working back and forth. I can confirm that the Adcock and shipley Bridgeport on mine is a normal Right hand thread I gingerley went both ways in the begining so as to avoid any damage but it came off ok. I tapped the drawbar with almost no effort and the spindle has started to come out of the quill the only thing is it has stopped, I think its like Paul said it has got caught on a quill stob knob screw or could it be that as I am only tapping the drawbar maybe that has caught on something, not sure what people use to tap the spindle out The question I have Paul is if I remove the stop knob screw and stop will anything fall to bits in doing so, I was wondering if the metal quill guard (telescopic thing behind quill screw) will be ok? Thanks to all replies Regards Richard.. |

| _Paul_ | 26/05/2014 00:21:43 |

543 forum posts 31 photos | You will be OK nothing else will drop off, the quill skirt is held on the quill by a couple of screws which you access from the top after taking the head off. As you only taking out the spindle this will not be affected. When disassembling the quill stop screw assembly what you may find and it’s quite common is the reverse trip ball lever is broken, all it takes is for the quill stop screw circlip to pop and the screw drops snapping the ball lever off, getting the remains out can sometimes be a pig. Regards Paul

|

| _Paul_ | 26/05/2014 00:30:21 |

543 forum posts 31 photos | Nearly forgot to mention make sure you have the quill lock on as once you take off the stop knob and screw there is nothing to stop the quill coming right out other than the handle clock spring and if that is jiggered....out drops the quill in the process this will damage the quill skirt. Paul |

| Les Jones 1 | 26/05/2014 09:30:28 |

| 2292 forum posts 159 photos | In situations when you don't know if a thread is right or left handed it is worth trying to see the end of the thread. If you can see the end you can work out if it is left or right handed. Les. |

| Richard Clark 1 | 26/05/2014 20:32:27 |

| 48 forum posts 1 photos | Hi to all, I removed the spindle did what paul said, it was the quill stop screw that was holding it from coming out. The spindle came out ok was not rusted or anything bad but I noticed that the outer spacer between the abec 7 bearings is loose moves side to side, the nut on the top of the spline is tight, I undid it and retightened it but it does not make the large outer spacer tighten up?. I also noticed that the dirt shield at the nose is able to spin too, does this mean that the abec 7 bearings are worn, the machine is 1970 ish, the bearings are RHP 7207 prec EP7 so they look original to me and the nut spider lock has not been messed with probably meaning nobody has been in there except me to see if it was tight. I did read somewhere but cant be certain that if the spacer between the lower bearings can move about then the preload has gone as the spacer should be tight without the nose cap. Am I right to assume worn bearings I get 8 thou axial play 1.5 thou radial on the guage when it was in the quill. Regards Richard.. |

| _Paul_ | 26/05/2014 22:31:10 |

543 forum posts 31 photos | If the spacer is loose it looks like your bearings are dud, it's the bearings pressing on the outer spacer that gives them light preload. Both spacers should be the same length preload is provided by the bearing. Depending on how long yours has run loose these spacers may have now suffered some wear, thankfully they aren't that expensive to replace try "Sorted.co.uk" for prices. Bearings prices are a different matter £200 to £300 for something the correct Abec 7 spec 2MM207WIDUL is the Fafnir designation. You do occasionally see new old stock on Fleabay. Paul

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in