DUH! I did it wrong Dad!!

| Oompa Lumpa | 09/11/2013 16:11:14 |

| 888 forum posts 36 photos | So, I need to machine this block and remove the black shaded bits so it is as thin as the long side - So now I have machined the long side, how do I hold it so that I can machine both sides? The piece is 35mm x 25mm x 1mm (approx). Any help would be gratefully received and I have plenty of this material so starting again would be no issue at all. This is sort of the machineing equivalent of painting myself into a corner I guess |

| Oompa Lumpa | 09/11/2013 16:14:33 |

| 888 forum posts 36 photos | Sorry, that should read 12mm thick approx, not one |

| MadMike | 09/11/2013 16:18:58 |

| 265 forum posts 4 photos | Errrrr. Flat on the table. Clamp the long thin face. Clamp the machine finish centre section and off you go, just mill the black areas down. You could mill one end at a time and clamp the other end for more rigidity. Other solutions are no doubt available. |

| JasonB | 09/11/2013 16:42:45 |

25215 forum posts 3105 photos 1 articles | Stick it in the vice with one black face against the movable jaw and mill away the top black face. Flip it over now holding by the central section and mill away the other face. Keeping the thin part against the thick jaw will make sure you keep both the same.

J |

| Chris Shelton | 09/11/2013 18:57:33 |

92 forum posts 46 photos | Could you clamp a bar across the middle, then mill each side of it? |

| Oompa Lumpa | 09/11/2013 19:28:17 |

| 888 forum posts 36 photos | These are all very good ideas and I thank you all for sharing them with me. Jason, would the piece hold in the vice? bearing in mind that is is no more than 1.75mm thick? Clamping a bar across the middle is certainly something that would work and enable me to mill both sides with one setup. Great ideas guys, thank you. |

| FMES | 09/11/2013 19:29:37 |

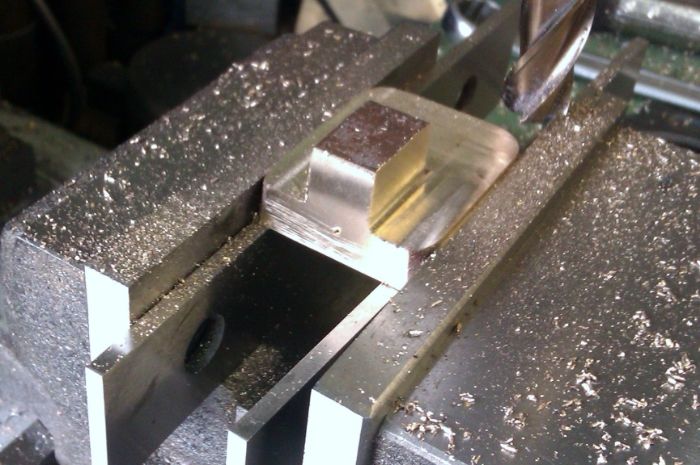

| 608 forum posts 2 photos | I wouldhave set it up in the vice on parallels and machined all three sections with one setup. Here's a pic of the nearest I can get to a recent setup, reducing a piece of 12mm steel plate down to 10mm. |

| JasonB | 09/11/2013 20:28:28 |

25215 forum posts 3105 photos 1 articles |

Jason, would the piece hold in the vice? bearing in mind that is is no more than 1.75mm thick? The way I suggest means you are holding it by the 12mm thickness. Hold in vice like this and mill away one black bit. You may need to pack it up on a parallel Then flip it and mill away the other Or a better photo of Loftys method, if you have 1.5mm in the vice and don't go mad it won't get pulled out.

Edited By JasonB on 09/11/2013 20:28:50 Edited By JasonB on 09/11/2013 20:32:17 |

| Paul Lousick | 10/11/2013 09:04:33 |

| 2276 forum posts 801 photos | If you start with thicker material you could hold in the vice as in Jason's photo, leaving a thicker section in the vice for rigidity. Then turn it upside down and machine the base (now the top) to the correct thickness. Another method is to glue to a base plate with hot melt glue and re-melt after machining. |

| Oompa Lumpa | 10/11/2013 20:28:09 |

| 888 forum posts 36 photos | Thank you everyone for all of the great ideas. I really must adjust my thinking a little, I think far too literally most days and not enough laterally. I am going to spend a little time using up a bit of Aluminium tomorrow and try some of these techniques. If anything, the most important thing I have learned out of this is to always cut against the fixed jaw of the vice. This has explained a gret deal to me and answered a good number of questions I had from previous errors I had made - but couldn't understand why. Thanks again. graham. |

| JasonB | 10/11/2013 20:40:03 |

25215 forum posts 3105 photos 1 articles | Just make sure you clock the fixed jaw true to the mill axis first |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

)

)

Register

Register Log-in

Log-in