Perfecto Lathe set up

Help and advice needed

| TheFatbloke | 17/09/2013 10:38:24 |

5 forum posts 1 photos | Hi I'm new to the forum (my first post)and relatively new to model engineering. I have recently bought an old Perfecto lathe at an extremely good price as it turns out. However I can not figure out how the motor unit and belt fits on. I'm pretty sure I'm missing a belt. I think it is very similar to a Myford 7 lathe, but I'm sure I will be corrected if this is not true. Does anyone have a similar lathe and could possibly post a photo of the motor/belt set up, I shall attempt to post some photos of it. I have looked for photos on line buy none show the bit I'm interested in.

Thank you Neil F |

| Ian S C | 17/09/2013 12:17:17 |

7468 forum posts 230 photos | NeilF, I'm sure that your lathe will require a jack shaft , and two belts, one from motor to shaft, the other from the shaft to the lathe. Some one else will know the ratios required for the pullies. Ian S C |

| TheFatbloke | 17/09/2013 12:31:33 |

5 forum posts 1 photos | I have a shaft that attaches to the lathe and motor that has a 90 degree bend in and a set of larger pullies, I'm thinking this is the jack shaft? I have looked at the photos on Lathes.co.uk but none of them show the lathe from behind or the way it all fits together. Thanks for advice.

|

| Grizzly bear | 17/09/2013 14:39:58 |

| 337 forum posts 8 photos | Hi TheFatblokePerfecto 3.5" Lathe ( See Post below).Regards, Bear..

Edited By JasonB on 17/09/2013 15:29:59 |

| Bazyle | 17/09/2013 18:39:03 |

6956 forum posts 229 photos | Can you manage some photos of what you have? "motor that has a 90 degree bend " sounds like a geared motor that would not be quite right for a lathe. |

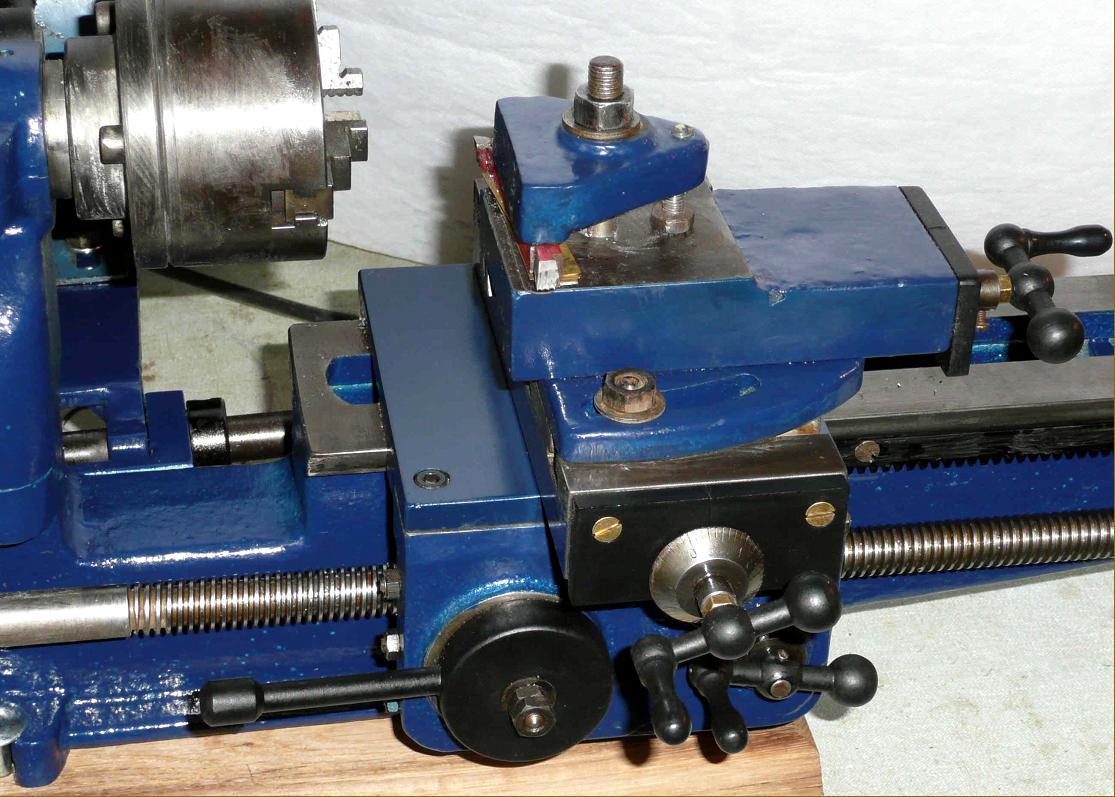

| TheFatbloke | 17/09/2013 19:23:10 |

5 forum posts 1 photos |

Some photos, anyone know what the thing that looks like a hammer is? |

| JasonB | 17/09/2013 19:39:44 |

25215 forum posts 3105 photos 1 articles | The hole at the end of the motor bracket Lines up with the hole in the lathe bed And the bent lay shaft acts as the pivot pin So it should look like this

|

| Stub Mandrel | 17/09/2013 21:23:24 |

4318 forum posts 291 photos 1 articles | Taa! Daaa! What a neat explanation! (Nice wee lathe too). But what on earth is the bit that looks like a hammer? Neil |

| TheFatbloke | 18/09/2013 05:59:53 |

5 forum posts 1 photos | Thanks Jason, so all I'm really missing is a belt. Got the lathe for £60, the deal was I get it back into use. The old chap that owned it is very ill and didn't want it going for scrap and I promised not to sell it straight on for profit. It is such a lovely old piece on quality engineering the was no way I was going to get rid of it in a hurry. I have stripped, cleaned and lubricated everything so ready to run once I get a belt and put a new switch and flex on it. The motor is so quiet and smooth I thought I hadn't switched it on

|

| Raymond Griffin | 18/09/2013 09:37:34 |

| 65 forum posts 48 photos | Hi NeilF, I attach a photo of my Perfecto lathe showing the motorization. The motor, pulleys and belts are held in a cradle made from aluminium angle. It came like this when I purchased it in the early 1980’s. I also have the leaflets etc. that came with it. There is also a useful chart of the gear ratios to the leadscrew. I can copy and send any of them if you wish. I learnt a lot about lathe work with mine and made some nice model steam engines. I hope that this is helpful. Ray |

| TheFatbloke | 18/09/2013 12:24:13 |

5 forum posts 1 photos | Thanks Ray that is useful, Ihave ordered a new belt. I would be very grateful for copies of the leaflets and charts. I will message you my email and home address so you can choose your prefered method, email would be good for me. I have also realised what the hammer thing is, a die holder as it has 3 grub screws in the correct position to hold them. I guess this is held by the tool holder. |

| cat psycho | 22/01/2017 11:28:56 |

| 1 forum posts 5 photos | hi guys , I've just bought this lathe too , I was hope if Ray wouldn't mind sending me a copy of the screw cutting charts & leaflets as well please & does anyone know the size/dimensions of the main shaft ? |

| phil1962 | 01/03/2017 11:14:41 |

| 51 forum posts 4 photos | As any fella still got a copy of screw cutting chart and info on lathe a long shot I know but any help would be grateful |

| Bazyle | 01/03/2017 11:52:30 |

6956 forum posts 229 photos | Don't worry too much about the specific manual etc for the lathe itself. It is virtually identical in operation to every other small hobby lathe produced from 1900 to 1980 like Drummond B up to Myford ML4 so many of the books and websites covering other makes will be useful reading. For screwcutting first check which changewheels you have and that the leadscrew pitch is 8tpi (99% probability). You will find they probably are mostly factors of 5 so can use Drummond and Myford tables but if you search the forum for screwcutting threads they will provide some links to programs that calculate how to manage with the gears you have rather than a tables. These are very handy.

|

| phil1962 | 01/03/2017 13:36:11 |

| 51 forum posts 4 photos | Posted by Bazyle on 01/03/2017 11:52:30:

Don't worry too much about the specific manual etc for the lathe itself. It is virtually identical in operation to every other small hobby lathe produced from 1900 to 1980 like Drummond B up to Myford ML4 so many of the books and websites covering other makes will be useful reading. For screwcutting first check which changewheels you have and that the leadscrew pitch is 8tpi (99% probability). You will find they probably are mostly factors of 5 so can use Drummond and Myford tables but if you search the forum for screwcutting threads they will provide some links to programs that calculate how to manage with the gears you have rather than a tables. These are very handy. Hi thank you the lathe came with 11 gears 2x20 then a 25.30.35.40.45.50.55.60.65 and yes leadscrew is 8tpi

Edited By phil1962 on 01/03/2017 13:39:29 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in