Unknown Machine ?

Rise and fall headstock

| John McNamara | 04/05/2012 08:19:32 |

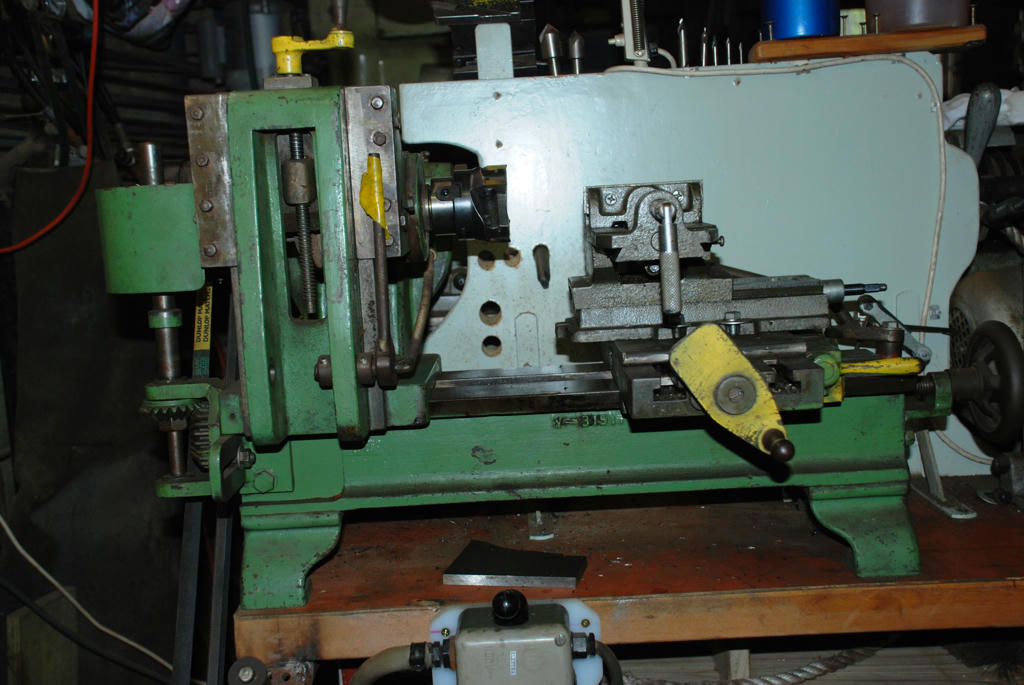

1377 forum posts 133 photos | Hi All A great friend showed me an old machine that has been in a family engineering shop for many many years. It looks like a small lathe, although there is no tail stock. The manual cross slide feed may be an add on also. The carriage itself is a T slotted table. There is a carriage cross feed connected to the spindle by gearing and a splined shaft, allowing the headstock can rise and fall. It might be a bench top horizontal borer? Maybe gear cutting? Does anyone know a little more about this intriguing machine? Thank You John McNamara Images Below: Edited By John McNamara on 04/05/2012 08:33:01 Edited By John McNamara on 04/05/2012 08:52:17 |

| mick | 04/05/2012 09:23:43 |

| 421 forum posts 49 photos | Horizontal borer? |

| Michael Gilligan | 04/05/2012 09:34:31 |

23121 forum posts 1360 photos | I can't identify it ... but it certainly looks a useful piece of kit ! MichaelG. |

| John McNamara | 04/05/2012 09:38:51 |

1377 forum posts 133 photos | It has me baffled? Please accept my apologies for links Rather than direct posted images could not get them to display after a number of trys. John M |

| Ady1 | 04/05/2012 10:09:13 |

6137 forum posts 893 photos |

Edited By Ady1 on 04/05/2012 10:10:50 Edited By Ady1 on 04/05/2012 10:11:58 |

| John McNamara | 04/05/2012 10:33:59 |

1377 forum posts 133 photos | Thank You Ady1 I must have posted hundreds of photos....Today it would not work, which Website button did you use? Was it the link button? Cheers John

|

| Ady1 | 04/05/2012 10:37:27 |

6137 forum posts 893 photos | Just the link you gave, and the forum software image link next to the "camera" when posting The hard bit is resizing it, a top number of 400 seems to work best |

| thomas oliver 2 | 23/06/2012 21:19:20 |

| 110 forum posts | I am not sure what the basic machine is, but I can positively identify the vise arrangement as I have an identical one. It is a cheap far eastern one. Mine cost £26 about 30 years ago. I use mine similarly but on my bench drill to do light milling using the slides. it seems this vise has been added for the same reason to give more axes of movement. The basic machine would probably have a toolpost for facing or boring. |

| GoCreate | 23/06/2012 23:22:50 |

387 forum posts 119 photos | A lovely little horizontal borer, as mentioned by Mick above. Very useful for boring, milling and drilling. Usually they have an optional adjustable support at the right hand side to support a long boring bar, similar to how you would use a boring bar between centres on a lathe with the work on the cross slide or vertical slide. The table has the usual x & y axis, the horizontal spindle moves up and down on a vertical guides. Nigel PS I want one Edited By tractionengine42 on 23/06/2012 23:23:19 |

| GoCreate | 24/06/2012 07:13:31 |

387 forum posts 119 photos | Also, normally the business end of the spindle has a powered slide for facing as well as boring.

Nigel |

| Steve Garnett | 24/06/2012 10:51:20 |

| 837 forum posts 27 photos |

Posted by thomas oliver 2 on 23/06/2012 21:19:20:

it seems this vise has been added for the same reason to give more axes of movement. Sorry, but I beg to differ - you don't get any more axes of movement at all with that arrangement unless you mount the x-y vice at some sort of rakish angle on the table. The saddle has x movement and the table itself has y movement, as is clear from the pictures. I have one of those x-y vices too, and I think that in terms of smooth x-y travel, I'd rather rely on the lathe, any day. If you have to have some arrangement like that for workholding, you'd be better off employing a proper milling vice rather than that thing - you'd get a far more rigid mounting, and inevitably better results. ****************************************************************************** No I don't know what the horizontal boring machine above is, but the principle is the same as that of the Murad Bormilathe. The difference with the Bormilathe is that it also has a raiseable and lowerable tailstock, although aligning the whole lot is a bit of a pain... when I eventually get around to rebuilding mine, I will post pictures, because it's quite unusual. Edited By Steve Garnett on 24/06/2012 11:11:19 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in