Printed gear tooth templates

| Rob McSweeney | 07/03/2023 20:14:41 |

| 98 forum posts | I was watching a YouTube video recently, where the contributor ground a gear cutting flycutter by cutting out a printed profile of the gear tooth and sticking it to the HSS blank. Anyone know where they got the printout from? |

| Pete Rimmer | 07/03/2023 20:23:09 |

| 1486 forum posts 105 photos | Probably GearDXF. Will produce a cad drawing of any supported gear you specify which you can then open and print out. |

| JasonB | 07/03/2023 20:25:40 |

25215 forum posts 3105 photos 1 articles | I've done it by printing out from a CAD drawing. Fusion 360 will do it for free rather than pay for Gear DXF Edited By JasonB on 07/03/2023 20:26:16 |

| Pete Rimmer | 07/03/2023 20:39:10 |

| 1486 forum posts 105 photos | GearDXF is free software Jason. https://www.forestmoon.com/Software/GearDXF/ I note that the newest version now outputs .STL files. |

| Bazyle | 08/03/2023 00:05:36 |

6956 forum posts 229 photos | In the end they are normally approximated by parts of circles. Therefore you could draw one BIG and reduce it in a photocopier, or by scanning and printing after using your photo programme to shrink it. |

| Paul Lousick | 08/03/2023 00:46:54 |

| 2276 forum posts 801 photos | Another online site for designing spur gears, 3D printing parts and other engineering services is .emachineshop.com (**LINK**) There is a large library of pre-designed parts. Gears can be designed in either inches or mm and exported as dxf or stl format |

| JasonB | 08/03/2023 07:15:54 |

25215 forum posts 3105 photos 1 articles | Peter, I was thinking of Gearotec, not GearDXF |

| Rob McSweeney | 08/03/2023 10:38:39 |

| 98 forum posts | Thank you gentlemen, l will have a play and see how l get on.

|

| JasonB | 08/03/2023 11:31:33 |

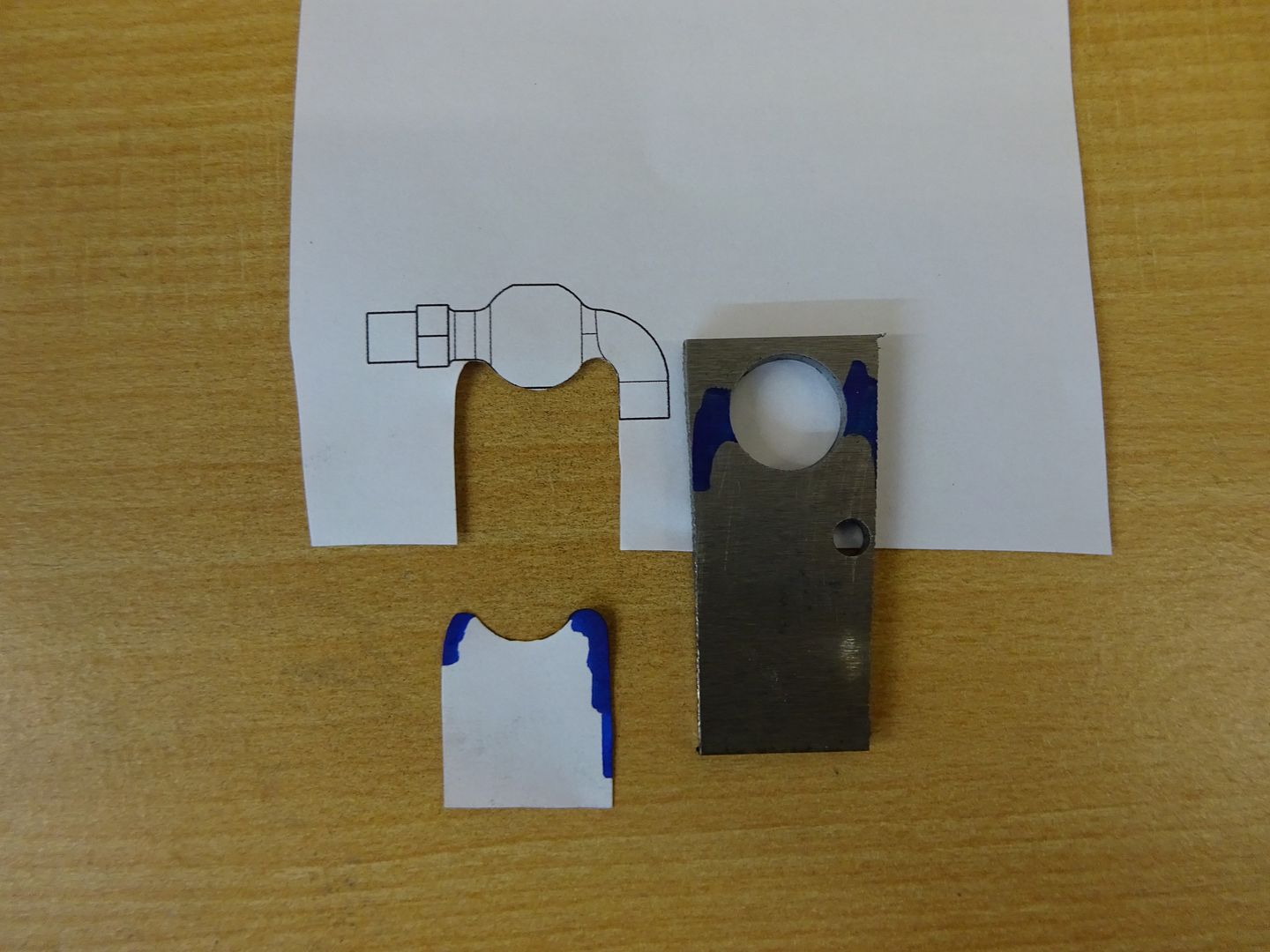

25215 forum posts 3105 photos 1 articles | Do you have a link to the video, were there printed on paper or 3D printed. As I said I have done it and I used paper, don't have a photo for gears but this is one for a form tool, printed 1:1 and cut out a piece, laid that on some gauge plate and used a sharpie to mark where to remove metal. remaining bit of paper can be used to offer the tool upto as you get close to shape..

And an internal gear where the cutter was shaped using teh same method

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in