Eccentric turning

Trunch Trojan sheave

| Arthur Goodwin | 22/08/2020 22:38:00 |

| 71 forum posts 45 photos | Hi all It is 54 years since I did my one and only eccentric turning as a fifteen year old in the training school. I am now faced with my second attemp in doing the eccentric sheave for my engine. My Q is would it be accurate enough to use a 3 jaw with a spacer on one jaw or do I need to use the 4 jaw with all its incumbent setting up. I have seen vids on you tube and the 3 jaw is certainly much easier. What do you guys advice. Regards Art |

| Hopper | 22/08/2020 23:21:12 |

7881 forum posts 397 photos | Yes you can use three jaw and packing. But the thickness of packing is not exactly equal to the offset you end up with . It's easier to use the 4 jaw if you have it. But one of the old books by either GH Thomas or Tubal Cain - I dont remember which - had a chart in it of packing vs offset. But you can play around with different packing Ang measure the offset with a dial indicator until you get it right.

Edited By Hopper on 22/08/2020 23:23:01 |

| Jeff Dayman | 22/08/2020 23:58:35 |

| 2356 forum posts 47 photos | Hi Arthur, Just FYI I don't do my eccentric boring on the lathe any more. I switched years ago to turning the OD and flange in the lathe, leaving the eccentric on a stub of the parent bar. I then load the bar eccentric end up in the mill, locate centre, step over by the needed offset, then drill and bore or ream on the mill. Less quesswork, in my mind anyway, no need to find packing exactly right, no risk of packing slipping out, etc. Just mentioning it as an alternate method. If you or someone you know has a mill, give it a go. |

| Paul Lousick | 23/08/2020 05:04:53 |

| 2276 forum posts 801 photos | My eccentrics are made the reverse of the conventional arrangement and have the female slot in the eccentric instead of the strap. Turning an external slot in the eccentric is easier than boring an internal slot in the strap. The faces of the eccentric straps machined and the casting bore cleaned up (left undersize). Position of cut marked out using digital readout on the mill. Holes for bolts drilled. Straps cut in half and the mating faces machined flat.

The 2 halves of the strap bolted together with a piece of shim material in between. (replace with thinner shim later to adjust the gap). The strap then clamped between 2 plates and centred on the lathe. Then the eccentric strap can be bored straight thru to the finished diameter. No difficult internal slots to bore. The outer, larger bore then turned. The strap then turned over to machine the opposite side. A dial indicator used to re-centre the strap but is not that critical as the outside recess is only a clearance fit with the mating eccentric.

Material for the eccentric being turned and and the strap used as a gauge for a running fit. Then parted off and face cleaned up.

Eccentric centred on the mill and an undersize hole drilled thru, using the DRO to measure the offset from the centre. Then returned to the lathe and used a centre in the tailstock to position the eccentric on the chuck. Chuck jaws carefully tightened to hold the eccentric in position for the filal boring of the hole. (could have used a boring head on the mill but did not have one at that time)

|

| JasonB | 23/08/2020 07:11:50 |

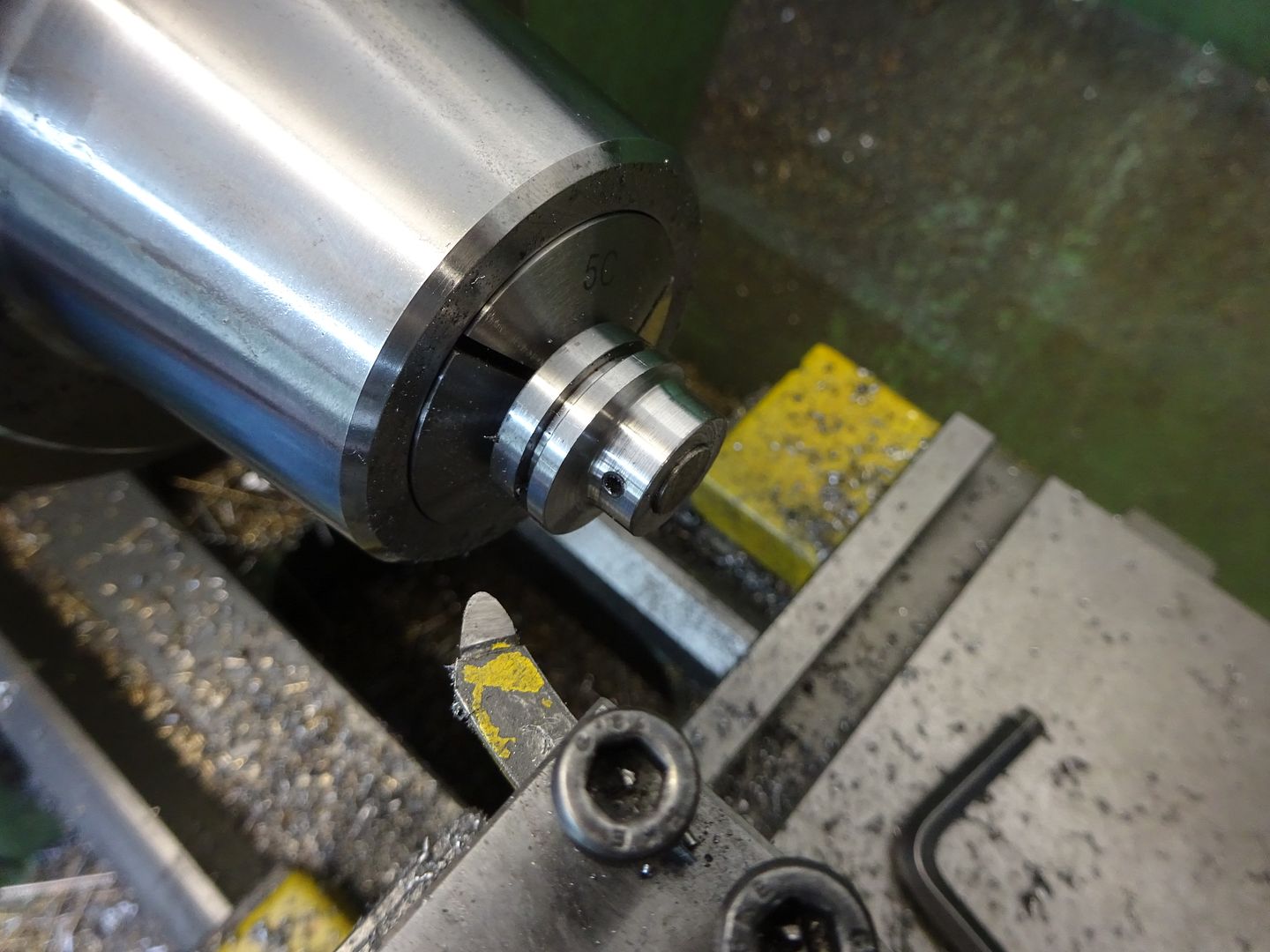

25215 forum posts 3105 photos 1 articles | Another vote for using the mill to put the hole in after turning the OD and cutting the groove. If you then drill for the grub screw you can use that to hold the eccentric onto the end of a piece of bar back in the lathe so that the boss can be turned concentric to the hole.

Edited By JasonB on 23/08/2020 07:13:38 |

| Roderick Jenkins | 23/08/2020 09:13:58 |

2376 forum posts 800 photos | Tubal Cain's formula for eccentric turning in a 3 jaw SC chuck: The shim mentioned is wrapped around the job to protect the finish from marking from the chuck jaws. I have used this method successfully. Stay well, Rod |

| Andrew Johnston | 23/08/2020 16:37:41 |

7061 forum posts 719 photos | I did all the boring and grooving on my eccentric straps and sheaves on the lathe using fixtures in the 4-jaw chuck. The assembled eccentric straps were located with four buttons for boring and grooving: Similarly the sheave was mounted on a plate for boring the offset hole: The plate is set true by indicating on the central hole. Not visible are two buttons at positions calculated to give the correct offset for the hole in the sheave. Andrew |

| Arthur Goodwin | 23/08/2020 16:52:06 |

| 71 forum posts 45 photos | Wow Thanks guys. Thats a lot of useful info to get my head round. Art |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in