Repair on cast base.

Metal puttey

| Paul Rogers 7 | 25/05/2020 18:52:53 |

| 22 forum posts | Hi.help please.i have done light damage on the cast base on my stuart Turner. S50.its not load bearing. Just a chip.i have heard metal puttey can be used then filed then painted. Is this right.if so what's the best one to get. Thanks Paul. |

| JasonB | 25/05/2020 19:05:13 |

25215 forum posts 3105 photos 1 articles | If cosmetic then car body filler such as UPOL "Easy" or good old P38. If structural then JB Weld but make sute it is "the original" formula. |

| Bodger Brian | 25/05/2020 19:38:46 |

187 forum posts 40 photos | Posted by JasonB on 25/05/2020 19:05:13:

If structural then JB Weld but make sute it is "the original" formula. Sorry for the ‘stupid’ question but how does one tell that it’s the ‘original’ formula? What’s the difference between the old & the new? Brian |

| JasonB | 25/05/2020 19:42:33 |

25215 forum posts 3105 photos 1 articles | It's the one with "original" on the packet and the red & black tubes. The Kwik and Marine are not as good particularly if you want it for it's heat resistance. Details |

| Bodger Brian | 25/05/2020 19:47:05 |

187 forum posts 40 photos | Posted by JasonB on 25/05/2020 19:42:33:

It's the one with "original" on the packet and the red & black tubes. The Kwik and Marine are not as good particularly if you want it for it's heat resistance. Details Ok - thanks for the explanation. I don’t need any now but it’s a useful thing to file away in the brain for future use. |

| Clive Foster | 25/05/2020 19:55:28 |

| 3630 forum posts 128 photos | For anything much beyond basic chip filling I've always gotten better results with metal loaded fillers. JB Weld tends to slump during cure if you try anything beyond fairly minor build up. Premium brands like Devcon are remarkably good with excellent adhesion and can be safely threaded. At their prices they darn well ought to be good! Of course when saving a £500 + or totally unobtainium part, £50 for filler is quite acceptable. You need to be sure that it will work. As ever a wide range to choose from at a wide range of prices. The art is matching duty, price and performance. Clive Edited By Clive Foster on 25/05/2020 19:56:03 |

| Paul Rogers 7 | 25/05/2020 19:56:29 |

| 22 forum posts | Thanks for the help. I will put jb weld on top of my shopping list. Thanks Paul. |

| JasonB | 25/05/2020 20:06:42 |

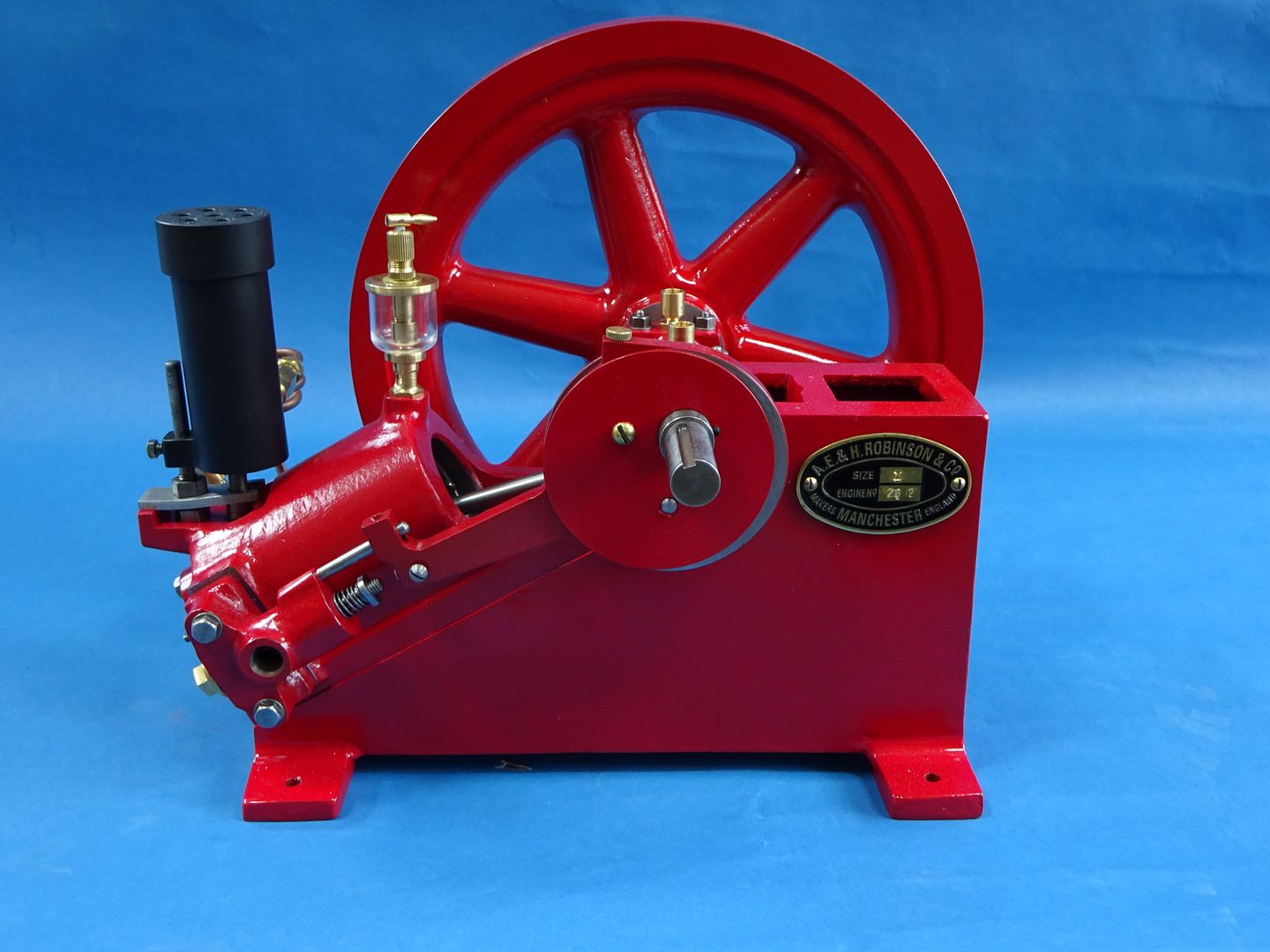

25215 forum posts 3105 photos 1 articles | If you let JB weld sit for a while it does not slump so much, you can also build a dam around an edge and it will flow to fill, masking tape is often good enough or a few small blocks with vinyl tape wrapped around them. It does contain metal powder. I know of a well respected ME contributor who used JBWeld to hold his soft jaws to the lower jaws and has tested a plug stuck in with the stuff to 600psi at which point his test rig would not go any higher. Like me he has also stuck steam engine cylinders together with it. Taps and drills too. Typical example is the foot on the left of this engine where the iron did not flow, should be like the one on the right, also faults where both feet meet the sides and a chunk missing from thebottom edge.

Can't tell anything was wrong

Another example where the fine raised lip around the bottom was damaged in the pattern along the side and at right hand end

Good as it should have been

Edited By JasonB on 25/05/2020 20:10:22 |

| Clive Foster | 25/05/2020 20:52:15 |

| 3630 forum posts 128 photos | He shoots. He scores. Thanks Jason for stepping up with practical advice and examples on how to use JB Weld as a filler. I only use it as a glue, and very good it is too. The only experience I have with it as a filler is when helping sort out where its gone wrong, often with folk whose general skill set is such that you'd not expect them to have issues. I shall certainly remember, and pass on where appropriate, that advice about letting it sit for a bit before using as a build up filler. I'm impressed that it still retains the ability to stick to the substrate properly after sitting. Most sticky stuff sort of skins over and rapidly looses the ability to stick to things first despite the mass being still flexible. Anyone moving up to Devcon or the other high end metal loaded fillers should remember that when they give a working time they mean it! Half a cans worth hitting the bin at a substantial, frustration fuelled, fraction of Mach1 'cos I didn't get on with things fast enough was a lesson expensive enough not to forget. Clive |

| Oily Rag | 25/05/2020 23:39:12 |

550 forum posts 190 photos | JB Weld can be surprising stuff - We used it to repair a prototype cylinder block which had the cylinder bores DLH coated onto the parent metal (aluminium alloy - LM25TF) one bore had a 'flake' of the DLH coating detach about a third of the way down on the GP axis. It looked like the flake was due to a casting imperfection in the parent bore (probably a blow hole or a piece of fluxing slag). To get the engine running, as we were working against a deadline, we used a dental pick to clean out the area under the flake and patch it with JB Weld - it was like being a dentist as the cavity was similar to some in my own teeth!. After 24 hrs we filed and scrapped the resulting repair to get it to bed in with the rest of the bore. Built the engine and gingerly ran it in, checking cylinder leakage % at regular hourly stops. It performed perfectly and went on to run for over 200 hrs on the test bed. It was a risk but worth taking as to get another block ready would mean a 4 week wait and cost £8K just for the DLH coating. As Jason says the 'original' is best - the 'Quick' and the 'Marine' (for use and application under water!) are not as mechanically strong, I did hear that it has now been discontinued from the original UK importer,but that someone else has started importing it.

Edited By Oily Rag on 25/05/2020 23:40:27 |

| John Rutzen | 26/05/2020 08:14:48 |

| 411 forum posts 22 photos | You can silver solder cast iron. Heat the bits red hot first which burns off any carbon. Then wire brush, use Tenacity No 5 flux and silver solder it. |

| Neil Wyatt | 26/05/2020 17:56:10 |

19226 forum posts 749 photos 86 articles | I made some 'cosmetic' marks in the bottom of the T-slots of the cross slide I made for my mini lathe, perhaps 15 or 16 years ago. I filled them with JB weld and despite much abuse and cutting fluid it's still there. Neil |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in