Hercules Steam Crane Tubal Cain

| BOB BLACKSHAW | 16/01/2020 18:15:25 |

| 501 forum posts 132 photos | I am making the steam crane but going by the book of Tubal Cain, I am not using any castings just brass and what's about in the shed. I cant understand the drawing in the book on the cylinder steam ports that connect to the standards. The standards have four holes, drilled No 46 but cant understand how this fits to the cylinders,the drawings are sectioned drawn as two holes. I'm obviously missing something here, any help please, I've made about 1/3 of it so far and hope to finish it. Bob

|

| JasonB | 16/01/2020 18:20:07 |

25215 forum posts 3105 photos 1 articles | Can you post a photo or scan of the page as I doubt many have the book but may be able to work out what the drawing shows |

| JasonB | 16/01/2020 18:31:00 |

25215 forum posts 3105 photos 1 articles | Just had a look at what it is like. The 4 holes in the standards are the usual two exhaust and two inlet holes you find on a double acting oscillating engine and there should also be a central pivot too. so the standard will look something like this

The cylinder will have a central pivot and two holes on the same diameter as the 4 in the standards and look like this

as the cylinder moves from one side to the other each end will alternately connect to inlet then exhaust. Like this Edited By JasonB on 16/01/2020 18:34:00 |

| Former Member | 16/01/2020 18:40:06 |

| 1329 forum posts | [This posting has been removed] |

| Maximiser | 16/01/2020 20:04:39 |

| 5 forum posts | There’s a brief explanation of how this type of engine works on page 14 of my copy of Tubal Cain’s book (Building Simple Model Steam Engines, 1997 reprint)(Chapter 2, Polly steam plant, introductory paragraphs). Edited By Maximiser on 16/01/2020 20:05:54 |

| BOB BLACKSHAW | 16/01/2020 20:05:38 |

| 501 forum posts 132 photos | Thanks Jason and Bill Its so obvious looking at the photos and the word oscillating, I had it fixed in my head that the cylinders didn't move. Looking forward to get it sorted tomorrow. Bob

|

| BOB BLACKSHAW | 16/01/2020 20:08:05 |

| 501 forum posts 132 photos | Thanks,Maximinster. Bob |

| BOB BLACKSHAW | 27/01/2020 12:31:59 |

| 501 forum posts 132 photos | I am making the cylinders out of brass and about to put the steam ports in, I was thinking of putting two condensation taps on the two cylinders. I have made a boiler and have tried it out on one of my stationary engines but had more hot water coming out of the exhaust as the cylinders were cold so I gave up on that. The boiler works well with a good amount of steam which incorporates a superheater. I will make a boiler as shown on the steam crane drawings but have others that have made the crane had the problem of wet steam, and would two taps make much difference. Bob |

| JasonB | 27/01/2020 16:09:10 |

25215 forum posts 3105 photos 1 articles | As nobody else has replied I would say add the drain cocks as it is easy to do at this stage as they can only help with getting rid of any condensate in the cold cylinders when you first start the engine. Or if you don't want to spend out on a pair of cocks you could drill and tap for them and just make up a couple of plugs then see how things go, if you get a condensate problem then just swap the plugs for drains. |

| JC54 | 27/01/2020 21:13:33 |

154 forum posts 14 photos | I would think that drain cocks would not be necessary on an oscillating engine. Surely the cylinder will lift off the standard allowing any condensate to escape? John |

| Former Member | 27/01/2020 21:30:29 |

| 1329 forum posts | [This posting has been removed] |

| Former Member | 27/01/2020 21:30:57 |

| 1329 forum posts | [This posting has been removed] |

| Bob Unitt 1 | 27/01/2020 21:45:00 |

323 forum posts 35 photos | I made one of these more years ago than I care to remember. I can't recall if the original boiler drawing specified it, but I piped my steam outlet down to the burner area and formed a loop of pipe to pass through the flame, gave me a bit of superheat. I also directed the exhaust into a glass screw-top jar fastened underneath the main platform,with an outlet through the screw-top - that kept most of the condensate in the jar, which i could unscrew and empty at the end of a run. I was surprised at just how heavy a weight the crane could lift, given that the boiler red-lined at 30 psi, very impressive.

|

| JasonB | 28/01/2020 06:57:32 |

25215 forum posts 3105 photos 1 articles | Well if a single acting with open end to the cylinder then only one would be needed but you can get single acting ones where there is a cylinder cover that acts to guide the piston rod so any steam getting past the the piston that condenses will find it hard to get out as the passage is on the other side of the piston. Regarding lifting off the port face again depends on the engine as not all have a simple spring, you can get ones that have a pivot on the opposite side to the ports with a screw adjuster that won't allow for any lift. Drains can also be opened and steam allowed to flow through the cylinder which will warm it which will help reduce condensate on start up. |

| Former Member | 28/01/2020 08:44:04 |

| 1329 forum posts | [This posting has been removed] |

| BOB BLACKSHAW | 28/01/2020 09:44:58 |

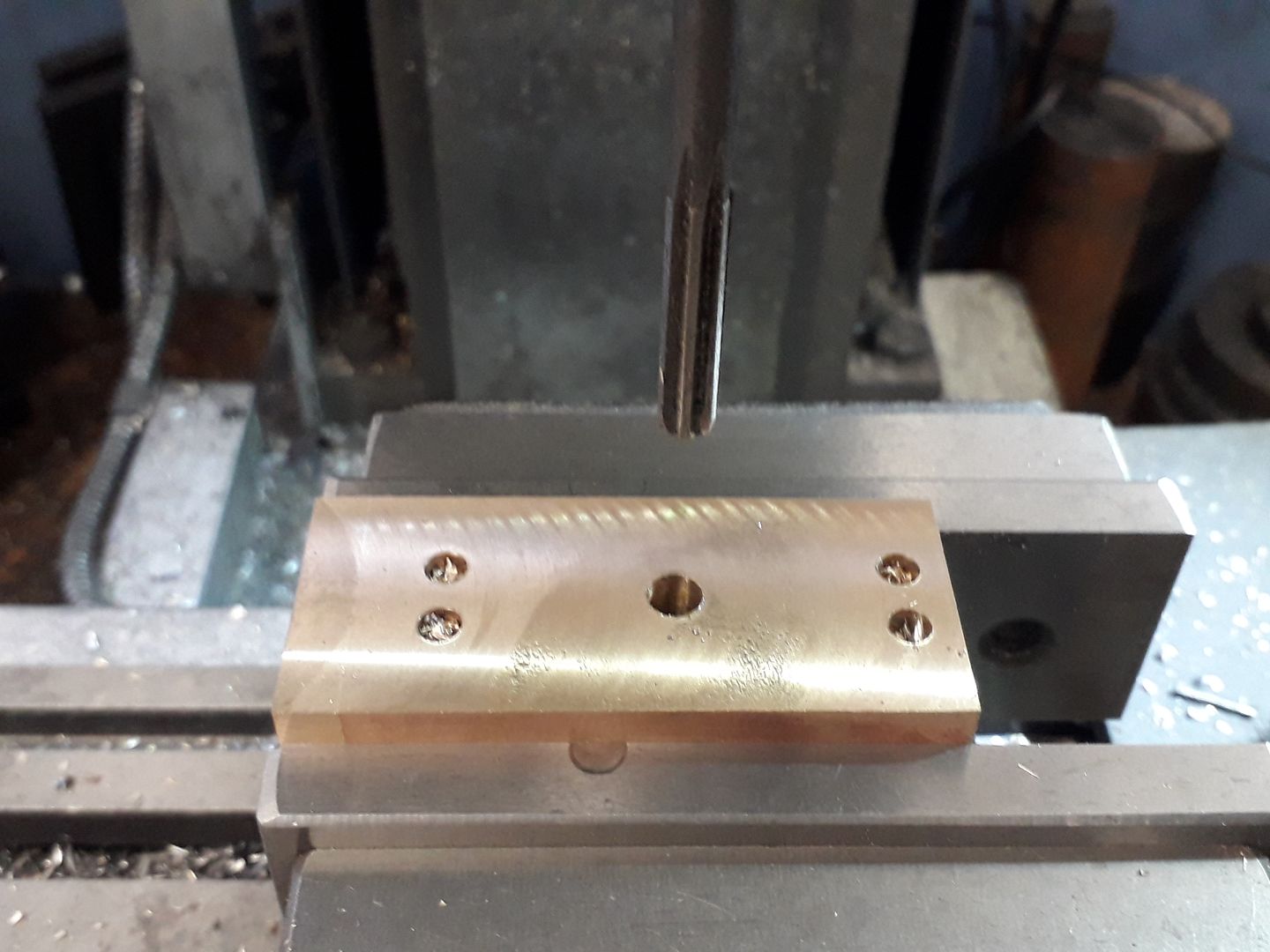

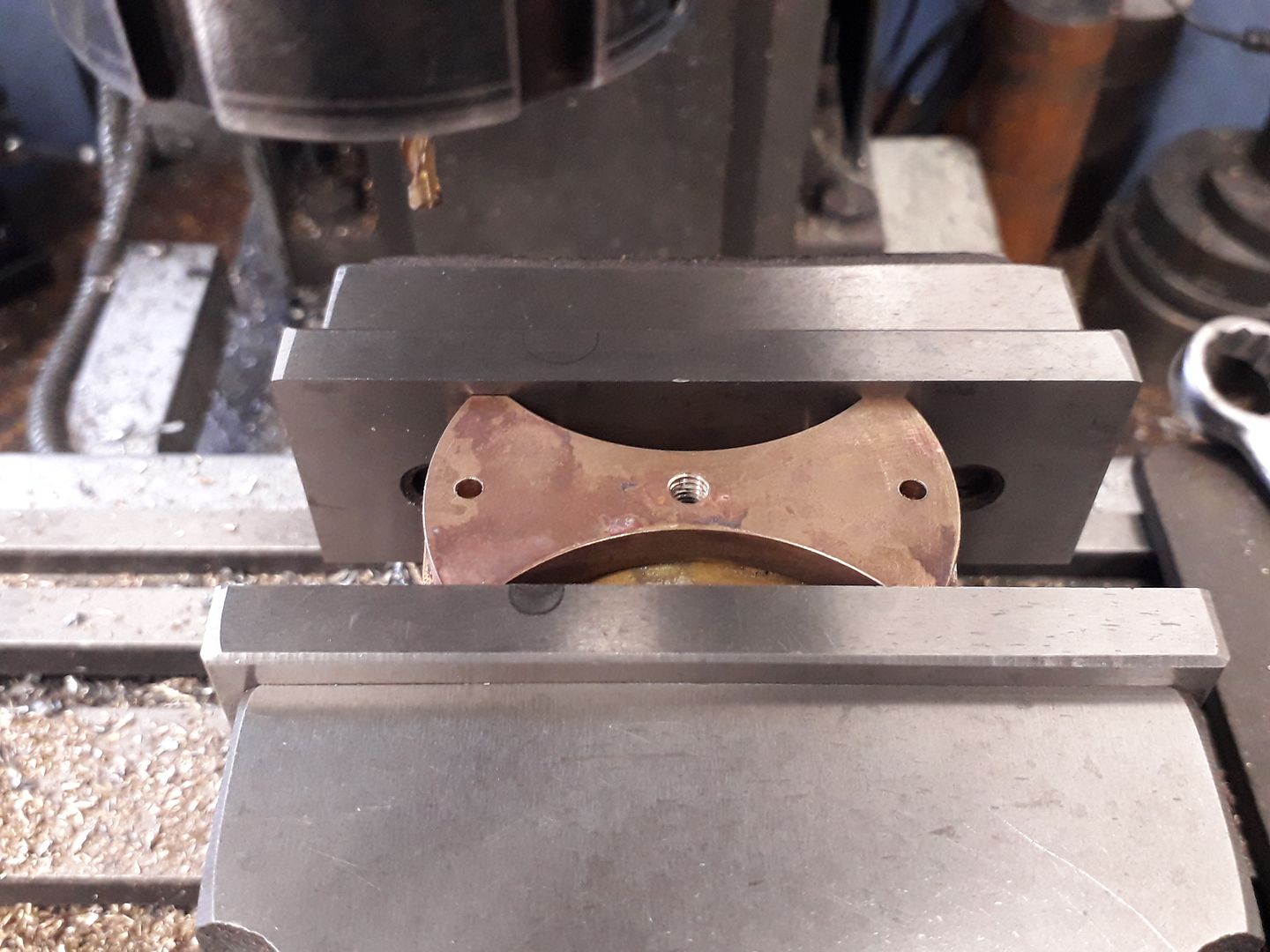

| 501 forum posts 132 photos |

A slow progress picture that Bill asked for. The large gear was slightly out of centre so I had to offset the bearings by .2 mm for it not to bind with the other gear, plus not as the drawing owing to what I could find in the shed. Bob |

| JC54 | 28/01/2020 09:51:14 |

154 forum posts 14 photos | Regards cylinder lifting off port face, I completely agree with you Jason about some oscillators not being able to lift off but after looking at the design for this engine/crane it can lift. It uses a spring to keep cylinder on portface. Whether you wish to add drain cocks or not is down to personal choice but Tubal Cain didn't appear to think them necessary. John |

| Former Member | 28/01/2020 10:25:28 |

| 1329 forum posts | [This posting has been removed] |

| Bob Unitt 1 | 29/01/2020 08:39:11 |

323 forum posts 35 photos | Posted by 34046 on 28/01/2020 08:44:04:?

Bob. I directed my exhaust straight back into firebox and up flue so heat would evaporate it. I tried that but it put the burner out |

| Former Member | 29/01/2020 10:37:14 |

| 1329 forum posts | [This posting has been removed] |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in