BF20/G0704 DRO mounting

Where'd you put the scales?

| Thaddeus Swarfburn III | 03/02/2018 21:16:59 |

21 forum posts 12 photos | Recently purchased an "SNS-3V" DRO from our friends at the website that rhymes with "shmalleyshmexpress". Looking at my options for mounting the scales. So far those suggested on this website seem to be best: **LINK** He has his X scale mounted on the front of the table. I was pretty set on the back of the table until I realised it would likely mean the removal of the table, which I'm not keen to do just yet. I would also have to modify the ways cover and haven't come up with an elegant way to do that. I didnt want to lose the table stops but then again, I've never used them on the Bridgeports at work in twelve years so... Where have you mounted yours? My machine is a BF20LV purchased here in NZ. |

| John Hinkley | 03/02/2018 22:45:25 |

1545 forum posts 484 photos | When I fitted glass scales and DRO to my Warco VMC mill, I made a slotted rail to go over the X-axis scale so that I could retain the travel stops as well as the power drive limiting stops. See the photo below. It may give you some idea of how I acheived it. ( The power feed limiters are the bits that look a little like railway buffers and the travel limit stops are the black button-like parts. ) I should add that, in the two years that the DRO system has been fitted, I've never used either the travel stops or the power feed stops and I have removed both in prparation for a house move and don't intend to replace them when the mill is reinstalled at the new place. The DRO is perfectly adequate for the accurate positioning and machining up to a pre-determined position, I've found. Just my view, mind. John |

| Thaddeus Swarfburn III | 04/02/2018 00:18:52 |

21 forum posts 12 photos | That's a nice clean install John. Did you bend up the scale cover or was it supplied? Mine came with covers but they're half again as wide as they need to be. |

| Paul Lousick | 04/02/2018 02:05:27 |

| 2276 forum posts 801 photos | I have an RF-45 (clone) milling machine and wanted to keep the front of the table clean and be able to use the table stops. The mill when purchase was coverred in a sticky protective grease which meant the dis-assembly of the table slides. This was not a problem and allows you to inspect all of all parts. While the table was removed, I drilled and tapped holes for mounting the DRO scales. A special bracket was made for the Y-axis scale. The supplied scale covers were modified slightly. This installation still allowed for the full travel of the Y-slide. Paul. |

| John Hinkley | 04/02/2018 07:44:02 |

1545 forum posts 484 photos | Thaddeus, The scale covers are as supplied, save for the short vertical section that abutts the table. I had to reduce that by about half, so that it didn't protrude above the top surface of the table. John |

| Thaddeus Swarfburn III | 04/02/2018 08:22:48 |

21 forum posts 12 photos | So I had another look with the intent on mounting it on the front of the table, and it looks like not only do I lose the stops but also complicate access to the gib clamps, which I can forsee myself wanting to use. I can probably remove the plastic handles and just use a nut driver to reach them, but this would also mean trimming the scale cover down to the point where it's hardly worth installing. I may just do this and if and when I take the table off swap it to the back. I think the right answer now is to just "get 'er done" and do something else if it doesn't work! What's the general consensus on covers for the scales? It doesn't seem as if the X is that vulnerable to swarf or coolant, though the way I plan to mount the Y axis scale (on an angle, as in the link in my first post) it looks like swarf could get between the scale and head.

|

| Enough! | 04/02/2018 17:07:05 |

| 1719 forum posts 1 photos | Posted by Thaddeus Swarfburn III on 04/02/2018 08:22:48:

So I had another look with the intent on mounting it on the front of the table, and it looks like not only do I lose the stops but also complicate access to the gib clamps, which I can forsee myself wanting to use.

Yes and yes. OTOH, if you mount it at the back you lose table travel. (Mine's mounted at the front). If you are careful with your mounting you can mostly regain the use of the gib clamps by extending their screws. I never really used the stops so they were no great loss to me. However, I do have a power feed which uses the same slot for limit switches - which the dro covers up of course. So I .... er ...... wing it. Edit: Covers (missed that bit). My experience is that this topic is a bit over-emphasised. That's not to say you can ignore it but it's never been (for me) the difficult problem that many seem to think. Common sense and reasonable precautions. DROs are more tolerant than you might think. Don't ignore simplicity if you want practical, as opposed to spiffy-looking. The best cover I ever used was simply a piece of polythene sheet taped above the top of the scale and draped over it. Probably worked better that any hard-fashioned device since you could give it more coverage and had the advantage of not crashing into such things as gib lock screws. Edited By Bandersnatch on 04/02/2018 17:27:21 |

| Clive Foster | 04/02/2018 18:40:58 |

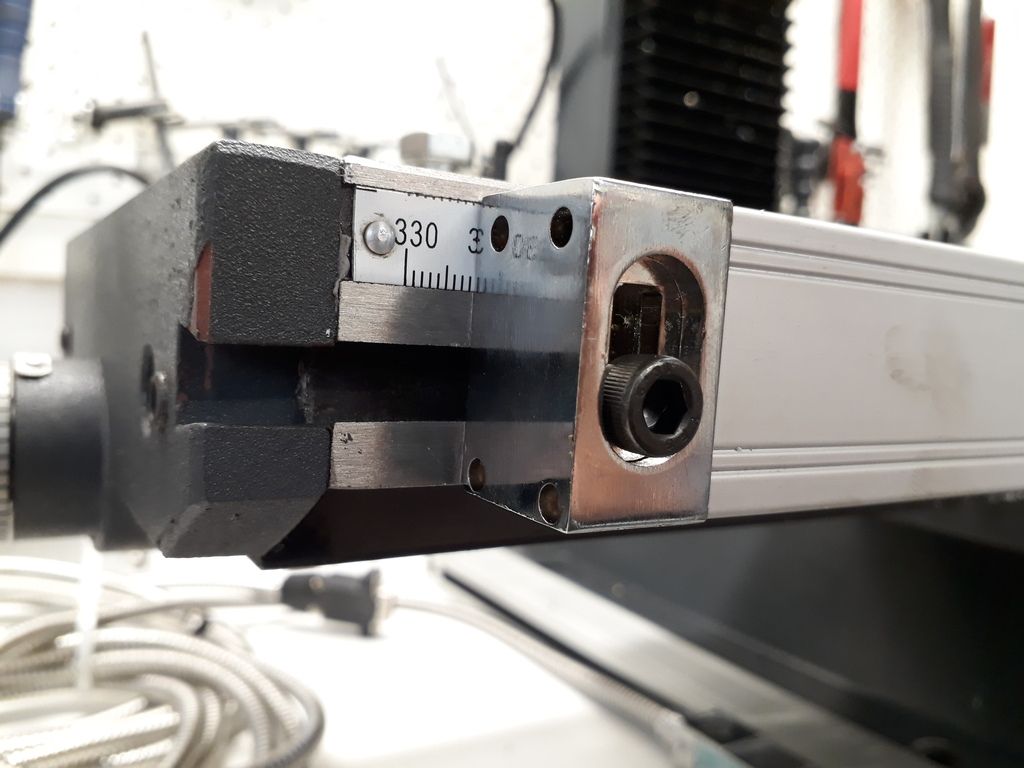

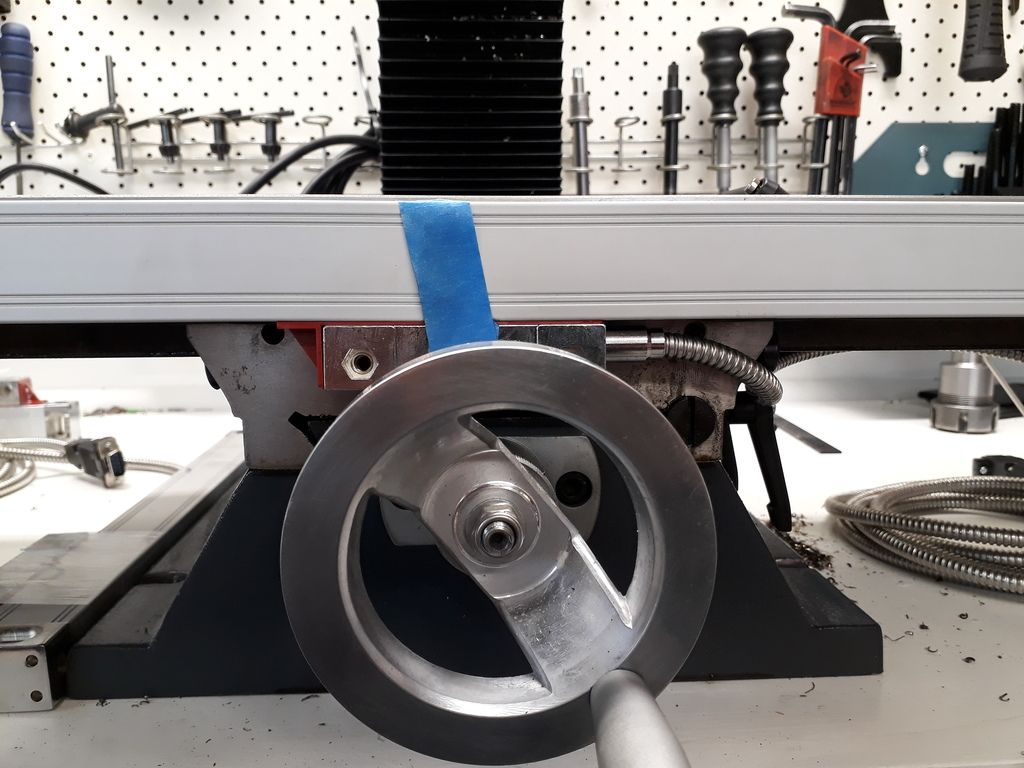

| 3630 forum posts 128 photos | When I fitted a DRO system to my Chester Lux style mill many years ago I reworked the stop system to make it shallower using an ordinary hex head bolt instead of the cap head provided. I left a space between the edge of the table for access to the adjustable stops and hex-head set screw for the which replaced the standard Bristol style handle on the lock. Changed the hand wheel for a folding type with a longer boss to win little more space. From memory the hand wheel only needed to be moved out about half an inch, maybe touch less, to find space for everything. Space for spanner can be seen in the picture. Only just enough vertical space for the glass scale above the slipways and hand wheel boss. These days I'd go magnetic every time on a small machine. Unlike Bandersnatch I used the X stops a lot on that machine. My normal practice was to mill with X axis whenever possible, setting the stops when verifying clearances and travel. This may have been because I frequently found table travel limiting. I now have a 49" table Bridgeport and almost never use the stops. Clive. |

| Dave Halford | 04/02/2018 20:49:00 |

| 2536 forum posts 24 photos | Just make sure you can't crash the scale end stops, it gives you wallet pain. |

| Paul Lousick | 04/02/2018 22:43:20 |

| 2276 forum posts 801 photos | Hi Clive, My mill looks like a later version of yours and sold in Australia as a HM-45 (RF-45 clone). Glass scales will fit at the rear of the table with a few mm to spare between the cover and the mill column. Paul. |

| Jon | 04/02/2018 22:48:15 |

| 1001 forum posts 49 photos | Mines on an RF45 known as many others inc Chester Super Lux, Warco and many others. Trust me you will need the bed locks and mounting on the front negates that. Its actually easier to fit on rear, four or five drill and taps, fit and away you go. Been 13 years.

|

| Thaddeus Swarfburn III | 11/02/2018 08:12:27 |

21 forum posts 12 photos | Just finished a big day in the shed and got the final axis done. I've posted an album here **LINK** I ended up not using any of the scale covers but will mount some rubber roofing scraps on the X and Y axes to keep swarf away. Very pleased with the result but fiddly clocking up the scales over and over with no power feed like the mills at work. I've been spoiled by big boy toys! I've already started researching driving stepper motors with Arduino. Was only planning the X axis but my injured shoulder that's not getting better is on the same side as the Z crank. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in