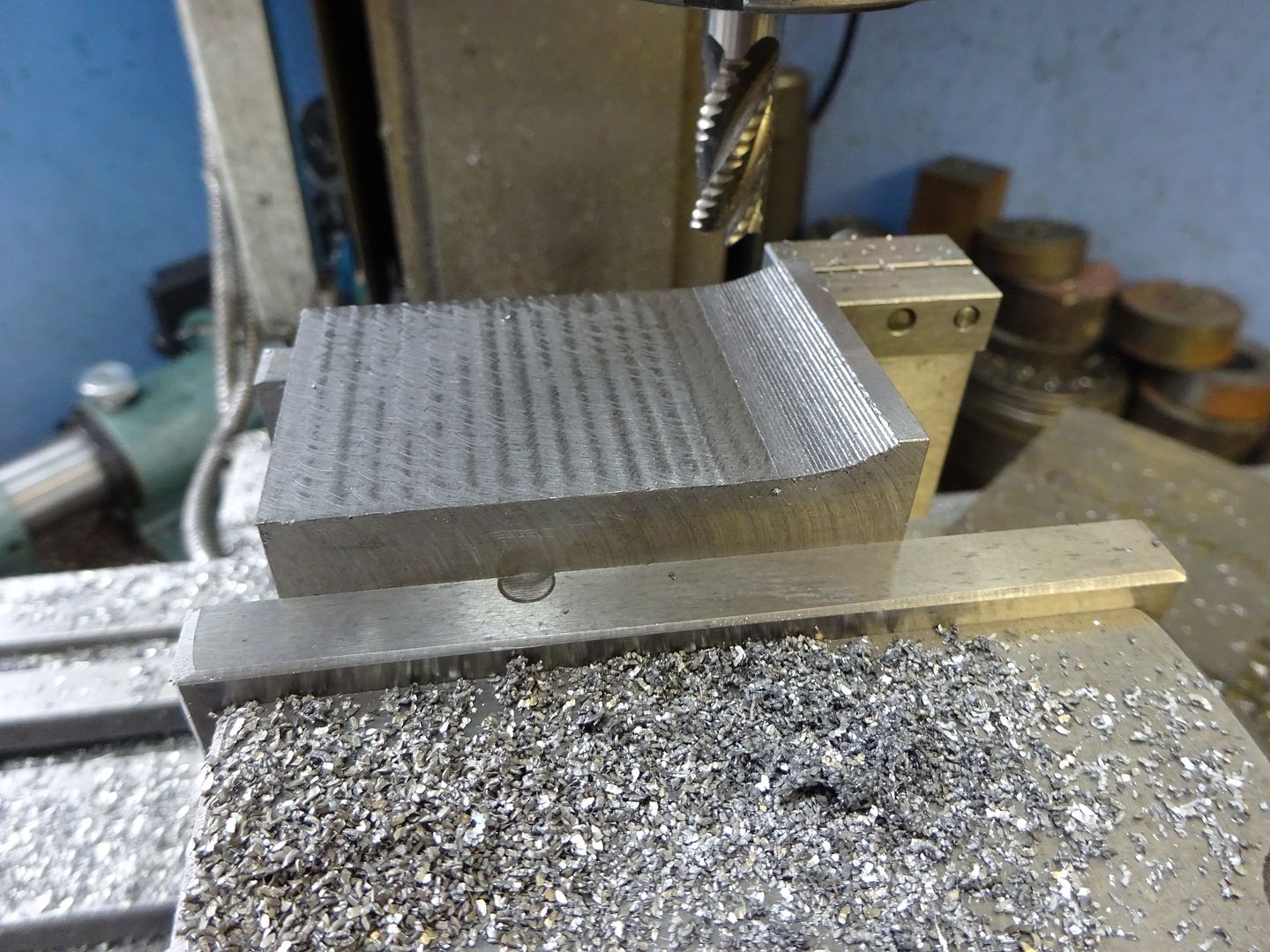

Milling curved groove

| Stephen Follows | 27/12/2017 21:10:46 |

119 forum posts 3 photos | I want to mill a groove with a 3" radius at one end in a 1" steel plate, (see diagram). Any suggestions on how to get the curve?

|

| roy entwistle | 27/12/2017 21:18:09 |

| 1716 forum posts | Ideal job for a horizontal mill Roy Edited By roy entwistle on 27/12/2017 21:18:32 |

| Hopper | 27/12/2017 21:37:43 |

7881 forum posts 397 photos | A flycutter with a piece of HSS toolbit set up at 3" radius would do the job. |

| Clive Foster | 27/12/2017 22:08:53 |

| 3630 forum posts 128 photos | If you use a flycutter to put the curve in as Hopper suggests its much kinder on the machine to rough out first to a series of steps on the curve with an ordinary end mill. Need to think carefully about tool tip shape grind and clearances if you need the curve to be exactly the same width as the slot with a sharp corner at the end. Much, much easier if you can allow a thou or two clearance on the side. Horizontal mill is the right way. Clive. |

| Tim Stevens | 27/12/2017 22:44:06 |

1779 forum posts 1 photos | In the absence of a horizontal mill I would set the plate up on its side on my vertical mill table, with the slot-to-be horizontal. I would then use a slot saw of 6 inch diameter to cut the edges of the slot, ending each cut at the curve. How wide a saw would depend on the power and rigidity of the mill, and the type of steel, but it wouldn't be a hobby-sized machine. Then perhaps a third parallel cut (or two) along the middle of the slot. Then I would find a wider blade of the same diameter and use it to remove the remaining sections. What I would avoid is any attempt to use a saw like this to cut only on one side of an existing slot. The blade would flex and try to follow the original slot, and quite likely jam if you were not paying 110% attention and had quick reactions. In the absence of a saw big enough the fly-cutter idea would be an alternative, perhaps using the same sort of technique with a relatively thin cutter, and with the end of the cutter ground square (ie not angled) so it would not deflect itself up or down. After all, what would this be but a single tooth saw-blade? The most difficult bit to get really neat, I suspect, is going to be the radius. A saw will make a clean job, but how it will cope when clearing the residual flanges depends on a lot of factors, including the sharpness of the blade (which might not be wonderful by then). It might be worth a try to leave the slot a few thou short, and finish the job by traversing the saw across the curved section several times, taking the most minute cuts each time and with plenty of lubricant. I will certainly be keen to read alternative methods submitted by experts. Regards, Tim |

| JasonB | 28/12/2017 07:06:37 |

25215 forum posts 3105 photos 1 articles | Lathe can always be used as a horizontal mill by packing the work up on the cross slide and having a suitable cutter on an arbor with tailstock support |

| Chris Evans 6 | 28/12/2017 09:59:19 |

2156 forum posts | If you apply the maths correctly it is fairly simple to work out the coordinates to get the shape with an end mill or slot drill. More maths though a bit more complicated and a ball nose cutter smooths things up. Can you get away with leaving a radius in the corner? Some of the latter/better DROs have a function to do things like stepping a radius with a ball end cutter. |

| Dave Halford | 28/12/2017 10:43:57 |

| 2536 forum posts 24 photos | Mount a three inch horizontal type cutter vertically on an arbour and clamp the work to an angle plate. |

| Chris Evans 6 | 28/12/2017 20:14:33 |

2156 forum posts | Posted by Dave Halford on 28/12/2017 10:43:57:

Mount a three inch horizontal type cutter vertically on an arbour and clamp the work to an angle plate. David, the OP is looking for a 3" radius so a 6" diameter cutter is required. Things could get a bit scary on a small machine. I would still do the maths to pick it out and a final flycut pass if required. |

| JasonB | 28/12/2017 20:26:13 |

25215 forum posts 3105 photos 1 articles | Depending what the final use is another alternative may be to mill a normal groove and then let in a curved piece, as Chris says easy enough to work out some co-ordinated and as it is easy to get a can soon be blended with a file.

Edited By JasonB on 29/12/2017 07:04:31 |

| Muzzer | 28/12/2017 21:29:15 |

2904 forum posts 448 photos | You sound as if you've been on the sauce again Jason! Or is it the spell checker? Use a tee slot cutter. Mount the work on a rotary table (axis parallel to spindle but offset) so that the outer radius of the cutter is at the required 3" from the centre of rotation. Then you can get a "perfect" slot shape rather than approximate / filed slot. Murray |

| Dave Halford | 29/12/2017 17:23:46 |

| 2536 forum posts 24 photos | Posted by Chris Evans 6 on 28/12/2017 20:14:33:

Posted by Dave Halford on 28/12/2017 10:43:57:

Mount a three inch horizontal type cutter vertically on an arbour and clamp the work to an angle plate. David, the OP is looking for a 3" radius so a 6" diameter cutter is required. Things could get a bit scary on a small machine. I would still do the maths to pick it out and a final flycut pass if required.

Ouch! Must try reading harder |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in