End mills for alluminium

| petro1head | 22/12/2017 13:00:37 |

984 forum posts 207 photos | I currently use Arc Titan coated 3 flute end mills - http://www.arceurotrade.co.uk/Catalogue/Cutting-Tools/Milling-Cutters/ARC-Premium-HSS-AL-End-Mills/3-Flute-HSS-AL-End-Mill-Standard-Length-TiAlN-Coated However they quite often get clogged meaning I have stop and scrape the alloy off the end of the tool. Any suggestions of what would be better. Ie 2 flute or split else |

| JasonB | 22/12/2017 13:05:19 |

25215 forum posts 3105 photos 1 articles | ARC's uncoated ones that are specifically made for aluminium work well for me though the 6mm can chatter a bit due to them being long series in which case I use nncoated FC-3 cutters. Or he does have standard length in carbide specifically for ali.

Edited By JasonB on 22/12/2017 13:18:24 |

| Mike | 22/12/2017 13:05:39 |

713 forum posts 6 photos | I think your problem may be that you are milling the aluminium either dry or far too dry. If so, lubricate with lots of paraffin or WD40. I've never known the number of flutes to make any difference. |

| JasonB | 22/12/2017 13:10:32 |

25215 forum posts 3105 photos 1 articles | The coating does not help as it is textured if you magnify it enough so the ali tends to stick to the rougher surface, that video only had a dab of paraffin before the cut wa sstarted. |

| Andrew Johnston | 22/12/2017 13:26:32 |

7061 forum posts 719 photos | There's no advantage in using coated cutters for aluminium. In particular the TiAlN coating needs to run hot (>800°C) to work effectively. So it'll never work properly when machining alumimium. There are polished cutters specifically for alumimium that will run dry. However, for manual milling an occasional squirt of WD40 works fine for me. On the CNC mill I use flood coolant, partly to prevent sticking but also to wash away the swarf and prevent re-cutting. If one is using sensible feeds and speeds then the number of flutes definitely matters. I only use 2 and 3 flute cutters for alumimium. More than 3 flutes greatly increases the probability of clogging the flutes. Like this Andrew |

| MW | 22/12/2017 13:40:41 |

2052 forum posts 56 photos | Cutters with polished flutes and high helix tend to work best for alu. |

| SillyOldDuffer | 22/12/2017 13:41:49 |

| 10668 forum posts 2415 photos | Aluminium has a low melting point and will glue itself hard to HSS if it overheats. Few suggestions in addition to Mike & Jason:

I have a love-hate relationship with Aluminium. It's beginner friendly until it bites back! Dave

Edited By SillyOldDuffer on 22/12/2017 13:43:06 |

| Jon | 22/12/2017 14:22:19 |

| 1001 forum posts 49 photos | Depends on the aluminium grade your using, some are a right pain. In short aluminium wont clog unless heats generated! Not keen on the high helix as cant generate fast enough spindle speeds, just lead to chaffing and ribbing. Would be nice to see a finishing cut put on Jason, bet the cutter veered off and why i only use carbide often TiALN it lasts hell of a lot longer. Down to 7/8" height on left x 1 3/4" width

Certainly for manual machining operators should learn to get a feel for whats happening. |

| JasonB | 22/12/2017 14:37:36 |

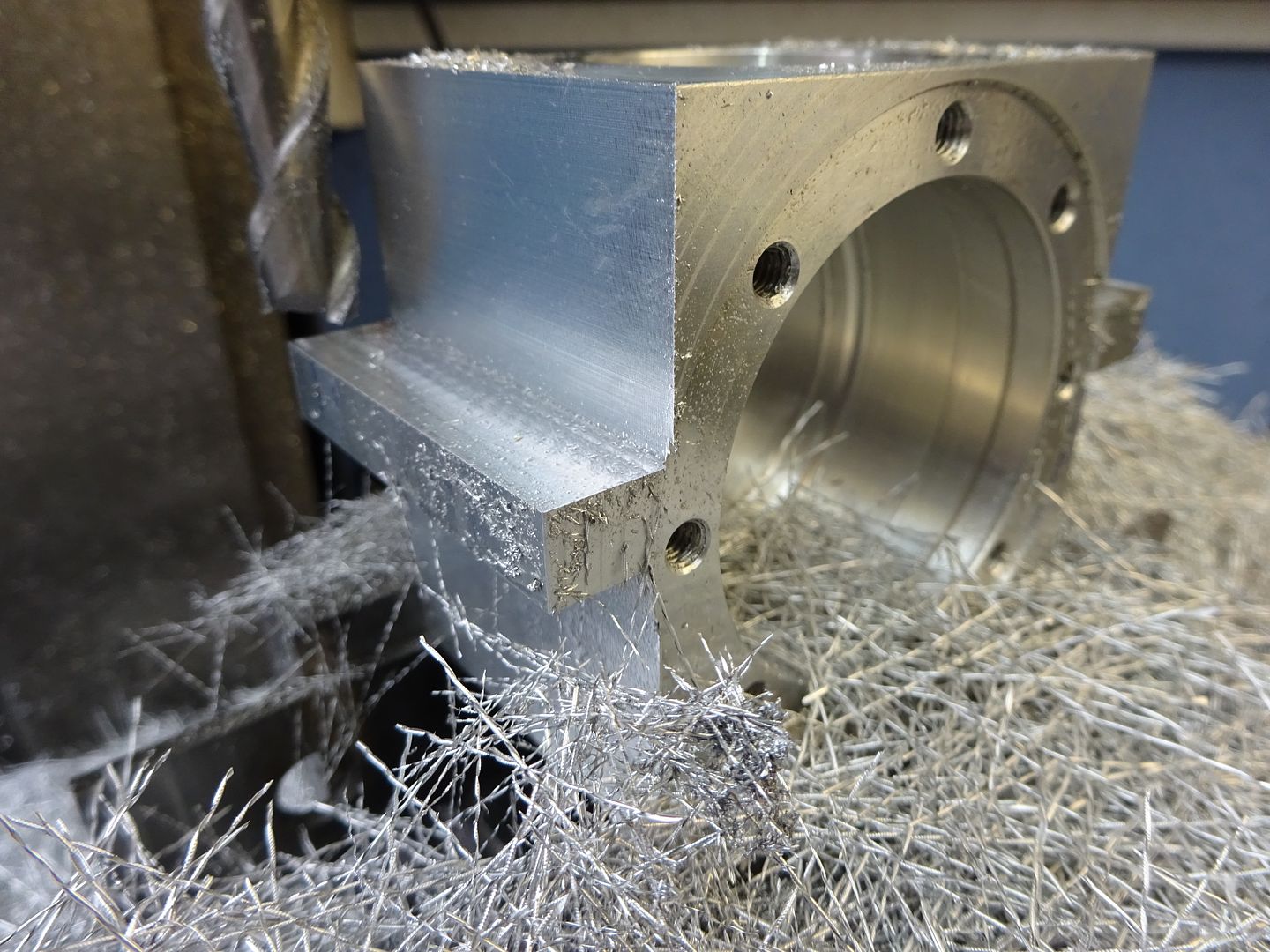

25215 forum posts 3105 photos 1 articles | Not got a finished shot of that part but was not aiming for anything special as there was a lot more metal to come off and then destined for paint, its the crankcase on this engine, mounting lugs were at the end of the cutter sides now rounded

Tell a lie, this was the cut but as I said not aiming for a finish just removing material

Edited By JasonB on 22/12/2017 14:41:16 |

| colin vercoe | 22/12/2017 14:56:14 |

| 72 forum posts | try using uncoated cutters the coating process forms a small radius on cutting edge so coated cutters are not as sharp as uncoated ones, they probably require higher spindle speeds as well, This also applies to carbide turning and milling inserts as well |

| petro1head | 22/12/2017 15:06:13 |

984 forum posts 207 photos | Yet again fab quick responces. From what I have gleaned: 1) Try not to use coated cutters 2) 2 or 3 flute but 2 seem to be an idea but the long ones can cause chatter 3) Lubricant like WD40 will help Sillyoldduffer made an interesting comment "over gentle cutting by the operator in the past." I am guilty of this always concerned I may be being too reserved with the amount I take off. A couple of mm at a time seems a lot but maybe I am wrong? The problem mostly happens when I am plunge cutting |

| David Jupp | 22/12/2017 16:27:31 |

| 978 forum posts 26 photos | Possibly even consider single flute cutters. |

| Andrew Johnston | 22/12/2017 16:41:27 |

7061 forum posts 719 photos | I think the pussyfooting cuts referenced by SoD might refer to feedrate rather than width or depth of cut? Depth of cut only determines which part of the cutting edge wears. To a first approximation width of cut doesn't have much effect on wear; it's a balance between each tooth staying in the cut longer versus few passes. What really wears the cutting edges more quickly than normal is too slow a feedrate. If the feedrate is too low as the cutting edge meets the work (assuming conventional milling) then instead of cutting it rubs and the cutter deflects. As the work moves eventually the forces due to a deflecting cutter overcome the material strength and the cutter starts cutting, and so on as the next cutting edge appears. This also means the cutting process is prone to chatter. A higher feedrate doesn't eliminate the rubbing but greatly reduces it, and thus reduces the wear. The extent to which the cutting edge rubs also depends strongly upon it's radius, although there's a trade off between edge sharpness and strength. For carbide cutters there is also a trade off on cost. Remember that carbide cutters are not homogeneous but consist of small particles of tungsten carbide in a carrier matrix, often cobalt, formed by sintering. The smaller the particles the more tungsten carbide is present, and the cutting edges can be sharper, but the more expensive the materials and hence the cutter. I thought my professional grade carbide milling cutters were sharp, until I bought a premium cutter. I managed to slice open my finger just getting it out the packaging. Andrew |

| Muzzer | 22/12/2017 16:48:21 |

2904 forum posts 448 photos | Not seen any evidence either way but I wouldn't be surprised if climb milling is less susceptible to swarf sticking on the cutting edge. That would be consistent with your point about too low a feed rate. I had a couple of breakages recently - these were the result of swarf not clearing from the work area and ending up being recut and subsequently stuck to the tool. For manual milling I'd say WD40 is essential along with uncoated, polished cutters. For CNC and decent removal rates, flood coolant is essential. I'm currently making a full enclosure for my machine, as I have concluded that the only way to clear swarf effectively is to use compressed air (or high pressure coolant which isn't going to happen here). With compressed air and flood coolant, things get very messy very quickly. Murray |

| Andrew Johnston | 22/12/2017 17:01:36 |

7061 forum posts 719 photos | Posted by Muzzer on 22/12/2017 16:48:21:

Not seen any evidence either way but I wouldn't be surprised if climb milling is less susceptible to swarf sticking on the cutting edge. That would be my intuitive understanding too. And, in general, for aluminium on the manual mill I get a much better finish climb milling. But I deliberately didn't mention climbing milling in case I got excoriated. Andrew |

| Muzzer | 22/12/2017 17:55:51 |

2904 forum posts 448 photos | Here's an example of swarf buildup that requires air to keep the tool safe. There are several occasions here where the tool movement and coolant flow simply aren't enough to clear the swarf. The last minute or so shows the final finishing pass, where large quantities of swarf are generated and without the air blast, much of it would have been recut, with a fair risk of tool breakage. Warning - not suitable for the likes of Seasick Neil, due to excessive camera movement! I had to keep dancing about ahead of the tool to blow the swarf clear with the airline. I already have a couple of videos of tool breakages, so that angle has already been covered... |

| Andrew Johnston | 22/12/2017 19:43:48 |

7061 forum posts 719 photos | Posted by Muzzer on 22/12/2017 17:55:51:

There are several occasions here where the tool movement and coolant flow simply aren't enough Hmmmm, man size cuts and swarf, but that coolant "flow" would put a small dog to shame. I don't expect much pressure from my coolant systems, but I certainly expect a decent flow rate. My CNC coolant can have trouble clearing a deep pocket, but it should cope with the situation shown. How big is the coolant pump? Andrew |

| Muzzer | 22/12/2017 20:01:21 |

2904 forum posts 448 photos | It's not the pump that's the problem - it's the size of the sump. I forget the capacity but it's brim full but still not enough. I can get a fine flow rate initially ("elephantine" perhaps) but it takes a fair time to percolate back down into the sump by which time the sump level is pretty low and the flow rate is seriously diminished. One solution would be high pressure, low flow rate (would require a new, different type of pump) or alternatively use the existing pump as a lift pump and fit an additional (larger) reservoir tank. That would involve a fair bit of buggerage and effort. And there would be a flooding issue if the lift pump didn't bother working. This machine wasn't expected to be using modern high speed toolpaths, although it is clearly capable of cutting the mustard so to speak - I suspect that when new (in the 1980s) the spindle motor would typically only achieve rated power when chomping through a large ingot. Most of the time it would have been mincing about, barely getting into a sweat. The problems I am having are the result of recent advances in toolpath generation and are exposing some of the differences between modern machines and older ones like mine. Murray |

| JasonB | 22/12/2017 20:08:19 |

25215 forum posts 3105 photos 1 articles | Would a smaller nozzle help to up the velocity without needing to increase flow, you could only go so far depending on whether the pump has the guts. |

| Jon | 22/12/2017 20:22:51 |

| 1001 forum posts 49 photos | I could make use of that Murray its what i was inferring above. For the unwise notice the steam that means heat and it has to go some where and aluminium holds heat. WD40 or spot coolant you would have to keep stopping every 2 seconds the job and tool would be hot more susceptable aluminium bonding to cutter . I do have a similar problem with lathe using a cheap small tank and pump but not the English originals about 4 times the capacity. Coolant builds up in height, drains and filters through mean while tanks almost empty. Larger tank. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in