Soldering bronze

| Eckart Hartmann | 06/12/2017 15:50:50 |

| 2 forum posts | I want to fabricate a cylinder + piston valve assembly in bronze by machining the different components with steam passages and then silver soldering them together. I have tried it out with brass and after figuring out how to silver solder properly it worked ok. The available bronze though (e.g. SA660) has >6% lead which some websites say can be soldered while others say you can not. I assume though most boilers have such bronze for fittings and it works fine. Can anyone report on good or bad experiences with silver soldering such bronze? Alternatively is there better option that does not rust? |

| JasonB | 07/12/2017 07:29:22 |

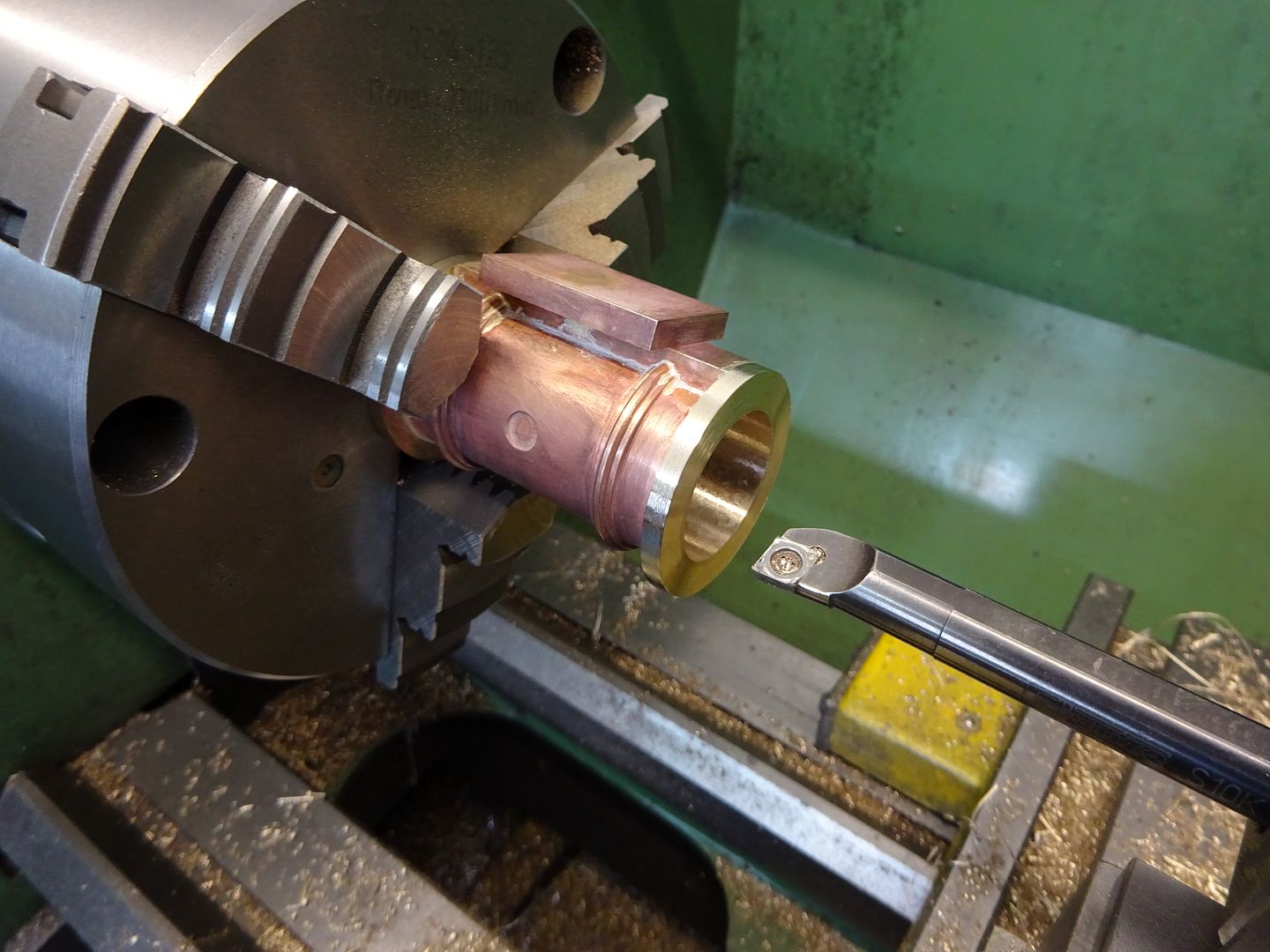

25215 forum posts 3105 photos 1 articles | I have not had problems silver soldering SA660 using just propane. If you use a hotter flame such as Oxy-acetylene that can make the lead contend boil out and weaken the joint. This cylinder is mostly bronze and the solder took well, hollow 660 for the main cylindrical part

|

| Keith Hale | 07/12/2017 09:24:22 |

334 forum posts 1 photos | Hi Eckart. Any problems associated with silver soldering are due tothe fact that the lead in the bronze ia not alloyed but is present as free lead. It is present as discrete lead inclusions. When heated, those on the surface melts. When the silver solder melts later, the molten silver solder dissolves it and and alters the composition of the silver solder. The silver solder becomes less fluid and penetrating. Overcome the problem by increasing the joint gap and so increasing the volume of silver solder. This dilutes the effect of dissolving the lead. Result ? Better, stronger joints. Of course, if the operating conditions allow it, you can always use a tin lead or tin copper soft solder. For more information**LINK** regards Keith |

| Eckart Hartmann | 09/12/2017 00:28:36 |

| 2 forum posts | Thanks for the replies. They both encourage me but I have found a reasonably priced source of PB1 bronze with 0.25% lead and/or I am considering using a 300'C tin lead solder. The parts are mainly held together by end pieces acting as a frame so the solder is just to keep the passages steam tight. I believe a 300'C solder should be good enough. If I go that way I will make a few test pieces to see how well the solder travels in the gaps. |

| Ian S C | 09/12/2017 11:29:40 |

7468 forum posts 230 photos | Eckart, as long as you tin the mating surfaces you should have no problem getting a good joint, just arrange for the parts to be held in position until it cools, the thinnest joint is the strongest. Ian S C |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in