Lathe gear setup problem

| Taris Jewell | 23/01/2017 21:00:39 | ||||||||||

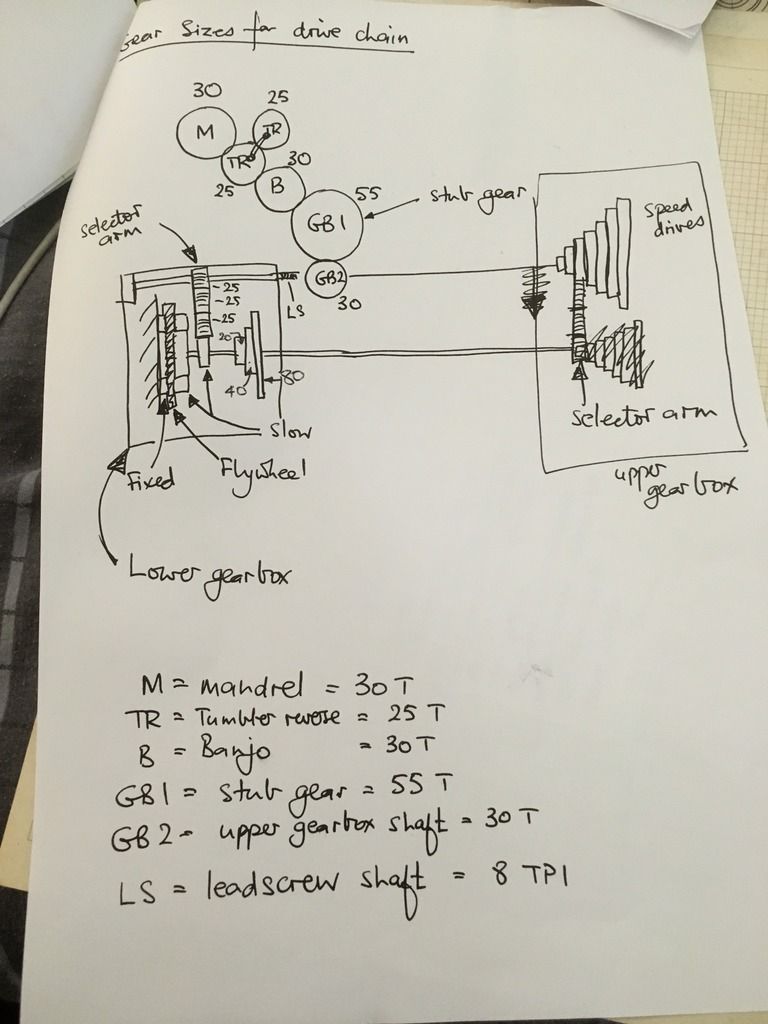

| 22 forum posts | Hello So the problem I have is that I bought a second hand lathe that is a Drummond but the auto feed/ thread cutting setup has all been replaced with a quick change gear box I think it is a myford one. Now the problem is that when I in gage the the auto feed it slips the gear labelled gb1 this gear is a 55 tooth gear with a 72 mm diameter the gears ethre side are 30 tooth but I don't know the size I think they're 40 mm now all the notes I have for the lathe the guy before me made when he converted it say that the dp is 20 for all Of the gears. i think that the gear labelled gb1 needs to be a 60 tooth gear and 78 mm diameter so it is still 20 dp but also a maltipall of 30. I think this because 30 doesn't go in to 55 but it does go in to 60 and the 55 tooth gear won't let the other 2 gears ether side turn as the mesh line isn't right because there are not enough teeth on the gear which the means the gears can't turn so it slips the gear please help if you can and ask for any more information and sorry about the spelling. | ||||||||||

| Hopper | 23/01/2017 23:41:00 | ||||||||||

7881 forum posts 397 photos | Welcome to the forum. I and quite a few others on here have Drummond M Types. The fitting of a Myfrod quick change gearbox sounds very interesting. Without seeing the set up I can't think exactly what is going on. It would help a lot if you could post some photos. The easiest way to do that is to post them to Photobucket or similar then copy and paste the DIRECT link from there into the box that pops up when you click on the photo icon at the top of the post pro-forma here, that is the little square icon to the left of the camera icon. The Drummond originally used 14DP gears which are huge when compared with the wimpy 20DP Myford gears. Is it possible you have a mixture of both on your lathe in the spindle and banjo area? | ||||||||||

| Bazyle | 23/01/2017 23:44:09 | ||||||||||

6956 forum posts 229 photos | If it has had a Myford gearbox fitted it is possible as you indicate that the rest of the gears are now the Myford standard of 20DP although the original Drummond gears are 14DP.

No idea what gb1 etc are referring to. You should be able to see and feel if the gears are meshing properly. It isn't necessary that 30 goes into 55 what is important is the ratio between the spindle rotation and the input to the gearbox. This depends on that the gearbox expects. The simplest thing is for a Myford user to tell us what the gears are on a regular lathe, then see how this compares to what you have. | ||||||||||

| Taris Jewell | 24/01/2017 09:52:59 | ||||||||||

| 22 forum posts | Here is a link to the picture and I shall try and get more later http://s61.photobucket.com/user/MISTER-T-1996/media/image_zpsapq0pju2.jpeg.html?filters[user]=146113923&filters[recent]=1&sort=1&o=1 | ||||||||||

| Les Jones 1 | 24/01/2017 10:25:18 | ||||||||||

| 2292 forum posts 159 photos | When you say " it slips the gear labelled gb1 " do you mean that it does not rotate whan the lathe spindle is rotated ? I assume the gear "M" is the gear on the lathe spindle and the two 25 tooth gears are on the tumbler reverse. If it is not slipping between the lathe spindle and gear GB2 the gar GB2 should rotate exacly the same amount as the lathe spindle as all the gears between M and GB2 are juts fillers. They have no effect on the ratio. Les. | ||||||||||

| Ady1 | 24/01/2017 10:44:40 | ||||||||||

6137 forum posts 893 photos | You have a virtually unique lathe from the sound of it so some pictures would be pretty essential IMO | ||||||||||

| Taris Jewell | 24/01/2017 11:36:51 | ||||||||||

| 22 forum posts | When I say slip gb1 the rest up to that point spin but the gear gb1 spins and didn't mesh with gb2 throwing it out of mesh but the gears fit together so I think they are both 20dp. When I turn it by hand it won't turn with the first gear box not connected so it is me trying to turn like 5 gears and it doesn't turn if that helps | ||||||||||

| not done it yet | 24/01/2017 11:53:30 | ||||||||||

| 7517 forum posts 20 photos | As Ady1 says, a picture might save a thousand words!

You may have a simple problem of the meshing adjustment not being sufficient or it needing a largergear to reach (that would possibly alter the gearing, unless it is an idler). DP gears are imperial and best described that way (no need for a 25.4 factor to be involved to convert to mm). Simply add 2 to the tooth count and divide by the DP (20 in this case) to give the gear outer diameter in inches. Conversely, measure the distance required, multiply by 20 and then subtract 2 from that result to give you the number of teeth required. There will be tables giving the centre to centre distances for any chosen pair of gears, I expect, which allows for the proper clearance when the two gears are engaged.

Edited By not done it yet on 24/01/2017 11:54:59 | ||||||||||

| Les Jones 1 | 24/01/2017 12:12:23 | ||||||||||

| 2292 forum posts 159 photos | Take a picture that shows GB1 and GB2. Then WITHOUT loosening the clamp on the banjo remove GB1 and take another picture. This will allow us to see if anything is preventing the banjo from allowing closer mesh between GB1 and GB2. Les. | ||||||||||

| Taris Jewell | 24/01/2017 19:15:05 | ||||||||||

| 22 forum posts | So I had a good look and the problem is the gear comes out of mesh between the bango and db1 I got the auto feed working going forwards or to the head stock but when I put it in to go the other way it locks up after doing this a couple of times it then when slip the gear going forwards so I think the problem may be with the mechanics that the bango is on moving and being loss as the gears seem to move up and down under lode I am going to try tittering it all tomorrow but if you have any other ideas it would help I have also uploaded some more photos http://s61.photobucket.com/user/MISTER-T-1996/media/image_zpslalvirsc.jpeg.html?sort=3&o=4 | ||||||||||

| Les Jones 1 | 24/01/2017 22:29:35 | ||||||||||

| 2292 forum posts 159 photos | THe studs on which the gears rotate are normaly fixed into a slot in the banjo. You need to adjust the position of the stud in the slot so the gears are meshing correctly. there maybe flats in the part of the stud between the banjo and the gear so that you can use a thin spanner to prevent the stud rotating while tightening the nut on the stud where it passes through the banjo. Les. Edited By Les Jones 1 on 24/01/2017 22:30:20 | ||||||||||

| Hopper | 25/01/2017 08:17:04 | ||||||||||

7881 forum posts 397 photos | OK, here is a sketch of Taris's set up he sent me by PM.

It looks like somebody has made a wonderful job of fitting up this gearbox! It looks to me like if GB1 and 2 are not meshing, then the stud that GB 1 mounts on needs moving by slacking off the nut on the back of it and shifting in the banjo. A picture of the gear train showing these gears as in the sketch would help too. Edited By Hopper on 25/01/2017 08:26:52 | ||||||||||

| Hopper | 25/01/2017 08:32:14 | ||||||||||

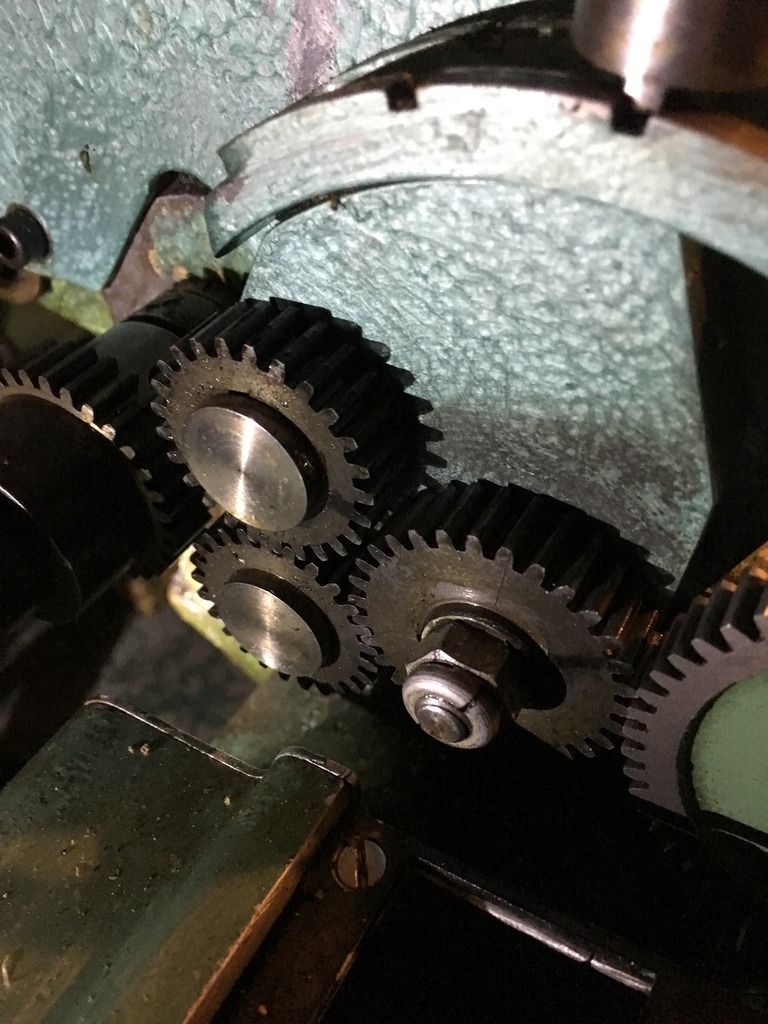

7881 forum posts 397 photos | PS: Aha, I have found the other photos in Taris's album so take the liberty of posting them here as this appears to be a most fascinating double gearbox set up, hooked up to the original Drummond reversing mechanism.

It looks to me like the problem may be the nut on the back of teh stud for GB1 needs tightening, when the gear is in the correct position. It is common to see these kinds of gears by putting a piece of paper between teh gears to make a small space of .002" or so when setting the stud position. It may also be that the Allen head bolt sticking out the front of the banjo needs tightening to stop the banjo moving.

Edited By Hopper on 25/01/2017 08:35:18 | ||||||||||

| Hopper | 25/01/2017 08:44:23 | ||||||||||

7881 forum posts 397 photos | PPS, Taris, that is no Myford gearbox. It looks like someone made it themself. There were several designs published in Model Engineer back in the old days. I have never seen a double gearbox set up like this one though. It seems quite unique. Also, the number of teeth on GB1 is not important, as long as it fits. It is only an idler gear so it will make no difference to the overall ratio, whether it is a 55 tooth or 60 tooth, or 160tooth. But if that is the gear you have on there, I am pretty sure it can be made to work by correct positioning of the stud and the banjo. What can you tell us of the history of this Drummond? Was it used in a factory or something like that? Someone has put a lot of work into it, with all the gears and the covers over the headstock and some modifications to the carriage by the look of it. Do you have more photos of the carriage and tailstock area of the lathe? You can get more information on this lathe type of lathe here **LINK** Edited By Hopper on 25/01/2017 08:44:40 Edited By Hopper on 25/01/2017 08:45:47 | ||||||||||

| Robert Dodds | 25/01/2017 13:51:12 | ||||||||||

| 324 forum posts 63 photos | Taris, From the photos it appears that when you move the reversing lever forward the carrier plate comes forward and is very close to the banjo arm that carries the 55 tooth gear. If they touch and prevent the detent pin on the reverser from engaging any torque on the drive will try to disengage the reverser gears. As Hopper says the 55 tooth is only an idler and could equally well be 60 or 65T and that would increase the clearance between carrier plate and banjo to allow the detent to lock in properly. Bob D | ||||||||||

| Taris Jewell | 25/01/2017 20:08:04 | ||||||||||

| 22 forum posts | So I moved the bango and the holder with db1 and 2 on but no success the gear seems to ether slip or bined i try everything I could think of but the gear is ether too far away or to close and now the last gear box seems to be binding up as well for something so simple is is so hard to get to work | ||||||||||

| Hopper | 25/01/2017 23:05:37 | ||||||||||

7881 forum posts 397 photos | It may be that you have tight spots and loose spots as a gear rotates. You have to set the clearance on the tight spot with a piece of paper between the teeth of the two gears. Starting from basics you might have to loosen the Allen head bolt and swing the banjo away from the other gears so GB1 is no longer engaged with B. Then set the clearance between GB1 and GB2 by loosening the nut on the right hand end of the stud that GB1 rotates on. This stud and nut is mounted in a slot to allow adjustment. Slide the gear GB1 up or down the banjo until a piece of paper fits between the teeth of GB1 and GB2 at the tightest spot of engagement. Rotate the gears GB1 and GB2 and make sure they turn freely with no binding. Tighten up the nut on the GB1 spindle at this point, then check again to make sure the gears did not tighten up when you tightened up the nut. Once you get GB1 and GB2 meshed correctly and spinning freely with no binding, you can now loosen the Allen head bolt on the banjo and rotate the banjo until GB1 and B are correctly meshed with a piece of paper between them for clearance. Tighten up the Allen bolt a little bit now. Rotate the gears and make sure there are not tight spots. If there is a big tight spot, put your piece of paper between the gear teeth at that point to set clearance and tighten up the Allen head bolt. Now it should all mesh correctly. This is the standard method for setting the gears on all lathes of this type. One other thing that can be adjusted is the position of the whole tumbler reverse mechanism (gears TR and the quadrant and lever on top) to make sure the TR gears are meshing correctly with M. This would be done before adjusting the quadrant and GB1 and GB2, but it sounds like in your case the TR gears are engaging OK so best not to move them. | ||||||||||

| Taris Jewell | 26/01/2017 20:31:10 | ||||||||||

| 22 forum posts | So I set up all the gear to the box and they seem alright but the gear box is solid i can move it about a corter of a turn and then it locks out I've oild the cleand and oild the gears but this has not worked but I'll leave it overnight and see but I don't know how much oil should be in the box as the gear aren't in the oil as they are should they be summarized in the oil they is also a grees nipple that I'll try. At the end of the second gear box there is a series of gears that I don't know what they do or if they are the problem as the gear box is pretty simple there is a rod with gears on that's it I know it's not the serlecter levers so what could it be. I've uploaded some more photos of the gear box if someone could help. By the way i tried turn the gears over by hand with nothing corrected to the gears and it didn't move as if it's like a barring sezed but i had it runing the other day so im not sure | ||||||||||

| Hopper | 27/01/2017 00:25:11 | ||||||||||

7881 forum posts 397 photos | It might just be tight meshing gears binding. Try engaging the gears and turning the lathe spindle by hand, without forcing it. You can post your Photobucket pictures on here by copying the DIRECT link from next to the picture in Photobucket. Then when you make a post on this site, click on the "photo" icon at the top of the post pro-forma. It is the icon to the left of the small camera, a small square with some blue and orange colours in it. When the window pops up from that icon, paste the Photobucket DIRECT link into the box where it says URL. Your photo will then appear on your post here. | ||||||||||

| Taris Jewell | 27/01/2017 07:24:12 | ||||||||||

| 22 forum posts | I've tried and it didn't work the shaft with the gears on dosent move regardless of any gears beeing ingaged |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in