two stroke on gas

reply for James Wells

| paul Longley 1 | 28/09/2016 18:53:00 |

| 10 forum posts | Hi there, just read Graham Astburys reply on running a two stroke engine on gas, whilst he's right on the simple two stroke engine, re oil supply, I'd like to add that a large number of two stroke stationary engines ( Petter, Kromhout, etc ) added fuel to the air in the transfer port so avoiding fuel contamination of the crankcase. This is VERY handy, given the risk of crankcase explosion. Most of these engines have a mechanical oiler, as Graham mentioned. Hope this is useful info, regards Paul |

| not done it yet | 28/09/2016 20:05:37 |

| 7517 forum posts 20 photos | Of course, one can run a diesel on gas (with a minimal injection for ignition) GM made an awful lot of two stroke diesels and none of them passed fuel through the crankcase. Not actually heard of them being run on gas, but lots of Lister diesels have been. Perhaps not simple enough? But certainly avoids blowing up the crankcase. If they were properly designed to run on gas, presumably there should be a bursting disc incorporated for safety? |

| JasonB | 28/09/2016 20:13:12 |

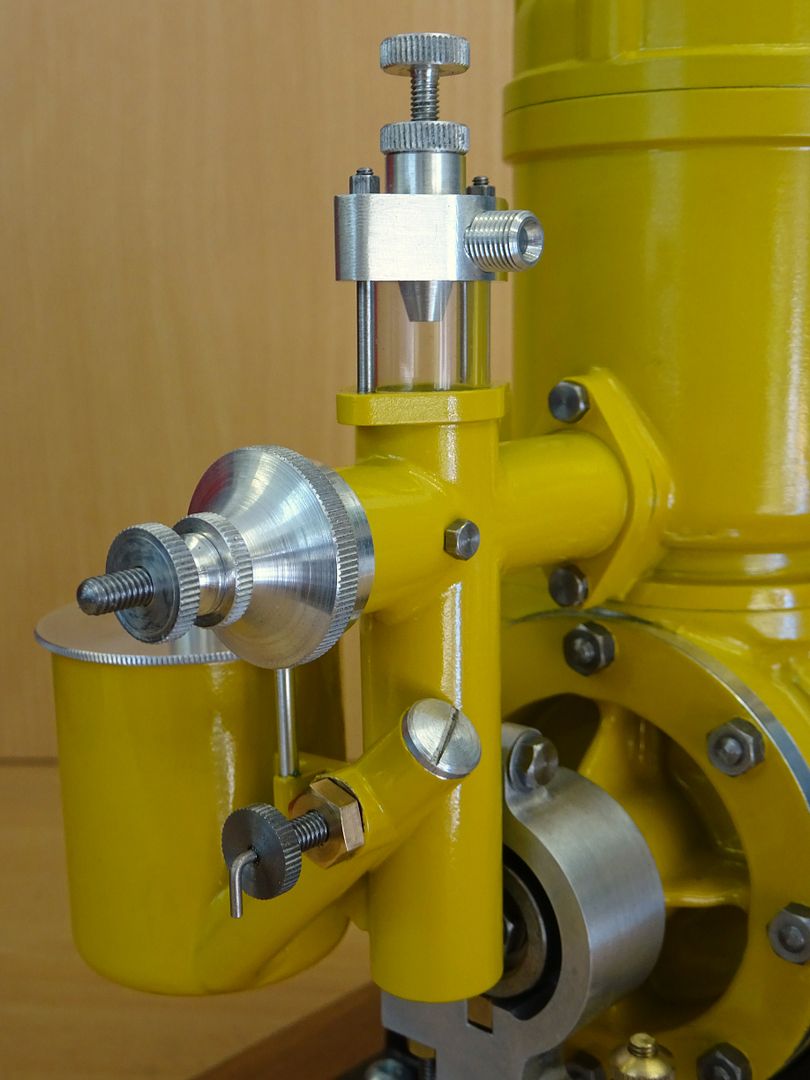

25215 forum posts 3105 photos 1 articles | Model two strokes can have oil added to the carb rather than just mixed into the liquid fuel so don't see why that should not work on gas as the oil is drawn in by the fuel/air mixture, much like this one I made earlier, oil fed from tank or pump, needle to adjust flow, sight glass to make sure its working.

|

| duncan webster | 28/09/2016 20:26:45 |

| 5307 forum posts 83 photos | I think you'll find that 2 stroke diesels didn't use crankcse induction, they used mechanical blowers to transfer the air into the cylinder, typically the Napier Deltic or the Commer TS3 **LINK** They could therefore have conventional pumped oil systems for the crankshaft lubrication. Edited By duncan webster on 28/09/2016 20:27:05 |

| paul Longley 1 | 28/09/2016 21:14:09 |

| 10 forum posts | The Petter, and Kromhout two strokes I'm thinking of aren't diesels. They're hot bulb engines, sometimes called surface ignition, or true spark ignition, as in the Petter little pet, universal, m type, etc. The spark ignition types have a jet in the transfer port, the distance from jet to piston is fairly critical. They use a butterfly or shutter inside the transfer port to control airflow ( to a degree ) The hot bulb types have full airflow, but inject fuel into the bulb ( vaporiser ) at the moment induction starts. The fuel then has time to vaporise, ignition being started by the fresh air charge entering the bulb. As has already been stated, most of the diesels use scavenging pumps, a few such as the Petter Harmonic or the Field Marshall use crankcase scavenging with a virtually constant loss mechanical oiler. But, to return to the point, admitting gas through a jet in the transfer port should be successful. Possibly a shutter in the transfer port to help the mixture proportions. With the shutter at low flow, the air pressure in the crankcase wouldn't get to high, it acts as a rebound cushion for the piston. Minimal air is taken in through the reed valves when the transfer shutter is closed. |

| Muzzer | 28/09/2016 21:17:26 |

2904 forum posts 448 photos | Slightly different situation but for interest, modern dual fuel commercial engines used in buses and coaches typically have an additional spark ignition system for when running on natural gas. So they operate as either diesel or SI. |

| not done it yet | 28/09/2016 23:02:58 |

| 7517 forum posts 20 photos |

2 stroke diesels didn't use crankcse induction,

Never say never, Duncan. Most two stroke diesels (like the GM's) used a rootes type blower, or similar, for scavenging and forced induction, but the prodigious Field Marshall 'Pop-Pop' single cylinder two stroke diesel tractor had a total loss lube system and worked with crank case compression for air induction. They were in use for some considerable period of time, although the drivers were likely well 'vibrated' after only a short driving spell.

We digress from simple two stroke petrol engines, but diesels do run nicely on 'gas oil', after all! International TD crawlers also had engines which were started on gasoline (spark ignition), then changed over, to compression ignition mode, to run on diesel.

|

| duncan webster | 29/09/2016 01:44:08 |

| 5307 forum posts 83 photos | I stand corrected. Not too long ago I saw a chap passing through my home town on a Field Marshall, Placard stated he was doing Land's End to John O Groats. All I can say is he must have been a glutton for punishment |

| Brian G | 29/09/2016 09:40:45 |

| 912 forum posts 40 photos | Does anybody remember Norton's "Wulf" stepped piston twin? This separated the oily bits from the fuel-air by using a stepped piston with the lower annular portion acting as a compressor for the other cylinder. If I remember rightly fuel lubricated the smaller piston rings, so it might not be suitable for a gas fueled engine without some form of cylinder injection. Brian |

| Gordon W | 29/09/2016 10:11:19 |

| 2011 forum posts | Can anyone tell me where to find the original query ? From J Wells ? I"ve searched the last few days worth with no luck. Interesting topic, do remember the stepped piston, didn't an east european company do a similar idea? Fuchs or jawa,or similar ? The old brain is going. |

| JasonB | 29/09/2016 10:22:38 |

25215 forum posts 3105 photos 1 articles | Postbag 4541 and the reply refered to in the opening post is in postbage 4544 |

| Gordon W | 29/09/2016 11:11:13 |

| 2011 forum posts | Forgive my stupidity-- please where do I find postbag4541 & postbage 4544. ? I've been using this site for a few years and never come across it. |

| JasonB | 29/09/2016 12:30:43 |

25215 forum posts 3105 photos 1 articles | Postbag is the letters page in Model Engineer magazine, the numbers are the issues that the letters appear in. The series about internal combustion by Graham Astbury was also in the mag over many issues. |

| Gordon W | 29/09/2016 13:49:13 |

| 2011 forum posts | Thank you, I thought it might be some part of the dark web, that lesser mortals don't have access to. Suppose I'll have to look for some old copies. |

| Tim Stevens | 29/09/2016 14:04:35 |

1779 forum posts 1 photos | Anyone who has difficulty with the above comments might find it helpful to know that there are two systems of two-stroke engine in common use. The Day Cycle used for motorcycle, lawnmower, chainsaw, model aeroplanes, draws the mixture into the crankcase and so, has to provide oil for the big-end, piston etc along with that supply. This can be by mixture or a separate feed or feeds. The other, Clerk Cycle, for bigger, mainly diesel engines, uses a separate pump to supply the mixture to the transfer ports, so the big end etc can be lubricated like a four stroke. There were much earlier stepped piston designs than the Norton Wolf engine - Dunelt in the UK (Coventry?) and DKW in Germany - both pre WWII. DKW also had success with motorcycles on the Clerk principle, one of which had two sparking plugs, five pistons, and a resonant exhaust system in about 1935. It was so loud that on a good day you could hear the TT from England. Regards, Tim |

| Neil Wyatt | 29/09/2016 14:34:49 |

19226 forum posts 749 photos 86 articles | Posted by Gordon W on 29/09/2016 11:11:13:

Forgive my stupidity-- please where do I find postbag4541 & postbage 4544. ? I've been using this site for a few years and never come across it.

In Model Engineer Issues 4541 & 4544, so you either need the back issues or a digital sub from HERE which also gives you access to the digital archive. Neil |

| Muzzer | 29/09/2016 18:14:11 |

2904 forum posts 448 photos | Back in the 90s, an Australian company (Orbital Corporation) was convinced that they were about to sell their 2-stroke technology to mainstream automotive OEMs including Ford. They kept the air-fuel mixture separate from the lubrication system by injecting it directly into the cylinder at high pressure. It seems to have failed on emissions and they then refocused on using similar technology to achieve stratified charge combustion in 4-stroke engines. In the event, stratified charge / gasoline direct injection / lean burn etc was successfully championed by Mitsubishi, Toyota, Ford, VAG themselves. Orbital still seems to be in business although these days it is apparently supplying engines for UAVs. There have been loads of weird engine concepts coming out of the Antipodes, almost as many as out of Russia. Must be something in their psyche.... |

| paul Longley 1 | 29/09/2016 18:43:23 |

| 10 forum posts | The stepped piston two stroke engine goes back I think to the first war era in some of the submarine diesels. I think the recurring problem was reciprocating weight, most early sub diesels appear to have used dedicated compressor cylinders. I remember seeing on tv years ago, Norton were using their Wankel rotary engines in UAVs as well as their motorbikes to help justify production machine costs. Could be the same firm mentioned above. The company Jenbacher Werke of Tirroll, specialise in gas burning diesels, I found out by accident when researching my 1956 Jenbach diesel ( only a single cylinder type) but again I'm digressing 😵 |

| paul Longley 1 | 02/10/2016 18:47:54 |

| 10 forum posts | Another tbought occours to me, the successful running of a two stroke engine on gas will depend on the type of gas. The free piston engines made at the end of the 19th century had little in the way of lubrication , they relied heavily upon the lubricating qualities of manmade town gas. Quite a bit of heavy vapour in it. I think there are quotes of having to strip and clean up some parts to return the engine to full power. The slide valves were a problem for some. So, a gas laden with lubricant may not be such an impossible option. |

| Howard Lewis | 04/10/2016 19:11:38 |

| 7227 forum posts 21 photos | The GM two stroke diesels were uniflow engines, where air entered the cylinder through ports in the liner, and the exhaust left via the poppet valve in the cylinder head. I think that the Foden two strokes may have been similar. The Roots blower was purely to provide "blow down" for scavenging, rather than supercharging. The Commer TS3, Napier Deltic, and Rolls Royce K Range engines, and possibly the larger Leyland engine (intended to power a Tank) by having opposed pistons operating in the bore, used one piston to control Inlet , and the other to control Exhaust. timings Since the induction air did not pass through the crankcase, and specific powers were higher, a separate lubrication system was used. The Rolls Royce C Range, and Perkins engines, that ran on gaseous fuels were not diesels, they were four strokes and used spark ignition. Most of the components below cylinder head level, other than pistons and rings, were common with the compression ignition parent. SAAB two stroke petrols used a separate lub oil supply system, I believe, which allowed higher powers. The Trojan and Sachs two strokes used a piston in a connected cylinder to provide scavenge air, (as did the Perkins Duplex - a two stroke diesel which never went into production). Quite a few two stroke diesels, used stepped pistons to provide scavenge air, but these were usually low speed units use for marine propuslion. I can see no reason why, for low specific outputs, oil could not be admitted into the Induction tract under the Throttle for a Gas engine. (basically that is what the loop scavenge two stroke does by adding oil to the petrol). Howard |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in