S 50

Milling the molded bolts

| Keith Rowe | 21/05/2016 11:36:27 |

| 20 forum posts 2 photos | Hi, I am a complete novice So I do struggle some times. I recently purchased a X2 mill and I would like to remove the molded bolts on a Stuart S50 I purchased some years ago. I am thinking the way to go is to first find the center of the molded bolt and drill it then mill the head off leaving the hole to be taped. If this is right how do i find the center of the molded bolt. If some one has a SIMPLE way of doing this Please enlighten me. Many thanks Keith. |

| Neil Wyatt | 21/05/2016 15:32:09 |

19226 forum posts 749 photos 86 articles | Hello Keith, Welcome to the forum. That seems a sensible way to do it, although you could mill the feature off and then drill for a stud. I assume you mean the ones that make the base look like two pieces fixed one on top of the other? Neil |

| JasonB | 21/05/2016 16:10:46 |

25215 forum posts 3105 photos 1 articles | If you pop a bit of rod into your chuck that is about teh A/F size of teh cast nut you can bring that down onto the top of the nut and eyeball it to get the rod central to the hex. I would then spot drill, drill tapping size, use an endmill or slot drill to spotface the area and remove teh cast nut in one go. you can then either use this surface for teh new nut and washer to bear on or go a little deeper and then JBWeld in a "washer" that can be fettled to look like a raised boss on the casting Counterbored hole

Washer added

Filled & painted

|

| Keith Rowe | 21/05/2016 16:26:50 |

| 20 forum posts 2 photos | Hi Neil, yes that's right but I am not confident about finding the center of the molded bolts if I machine them off first I think I would be even less confident. I was hoping some body could give me a simple way to center the mill on the molded bolts only when I do machine the molding I would like to keep the little mold pad under the bolts. At the the moment for me it's like the north face of the Eiger. Many Thanks Keith |

| Michael Gilligan | 21/05/2016 17:44:42 |

23121 forum posts 1360 photos | Keith, You might follow Jason's general method but, instead of chucking a rod in the mill, chuck a box spanner that fits the dummy bolts ... it will be a faff, centering it, but at least you will know when you're there. MichaelG. Edited By Michael Gilligan on 21/05/2016 17:45:31 |

| Neil Wyatt | 21/05/2016 17:49:27 |

19226 forum posts 749 photos 86 articles | Either use a rod as Jason suggests, or try a sticky pin. Stick a pin to the end of your chuck with blu-tack or plasticene so its more or less central. Running the machine very gently nudge the pin with the edge of a ruler until it runs perfectly true. Use this to line up with the moulded studs. You can buy a posh version, called a 'wiggler'. Neil |

| Keith Rowe | 22/05/2016 16:22:44 |

| 20 forum posts 2 photos | Hi all, I have found a darning needle and some blue tack also a piece of bras tube that fits snugly over the molded bolt, I have been having a practice and feeling much moor confidant now. Thank you all for taking the time and trouble to point me in the right direction. Many thanks Keith |

| Michael Gilligan | 22/05/2016 16:28:27 |

23121 forum posts 1360 photos |

Let us know how you get on, Keith MichaelG. |

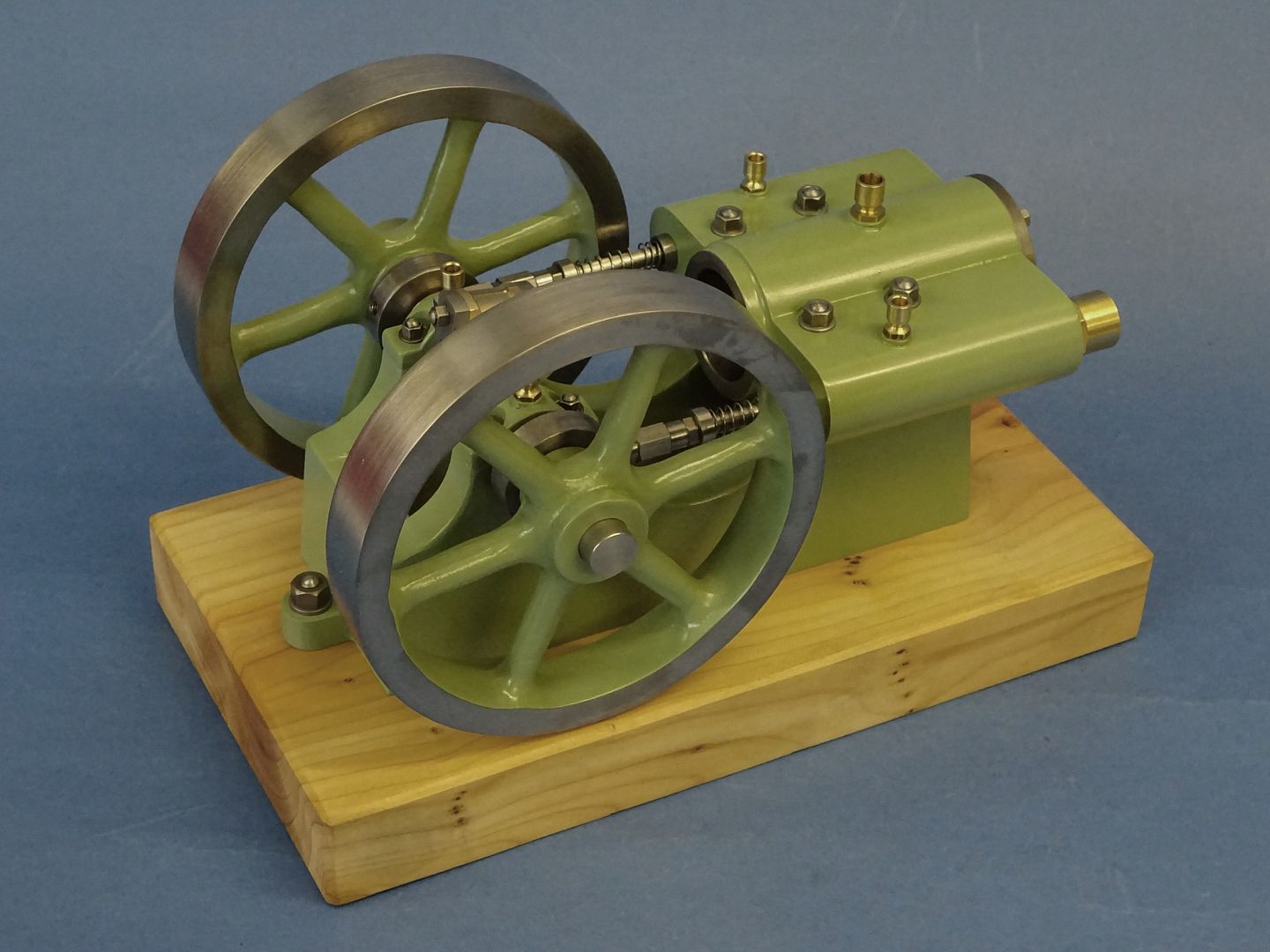

| Keith Rowe | 30/08/2016 20:44:03 |

| 20 forum posts 2 photos |

Hi all, sorry it's been so long but some thing came up. As you can see from the photos I have achieved what I wanted, in the end I went with the Wiggler so much so I have purchased one.Thank you all for setting me on the right track. Sorry one photo is upside down but I don't know how to turn it around hope this is OK.

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in