Cutter size too big for collet work around

| Ady Wilson | 11/05/2016 18:05:54 |

| 41 forum posts 14 photos | I have a block of aluminium roughly 100x30x20mm which I need to mill so it will mate onto a tube. So I need to match radius of the tube which is 7/8 of an inch diameter. I have made a mistake by buying a 7/8 ball mill which has a 1 inch shank. I never thought it out and know realise that I cannot hold the tool in the mill. Spindle is MT3 and collets wont take such a shank. I have a lathe but no milling slide so cant go that route. I havent tried but I am guessing trying to turn the cutter to a reduced shank size would be futile? Would I be wasting time and tooling trying ? Is there another way to put the radius onto the block? I need to put it down the longest side. I dont want to do it by cutting a V into it I need it to look nice and be a radius. Any help much appreciated, Ady. |

| Martin Connelly | 11/05/2016 18:23:50 |

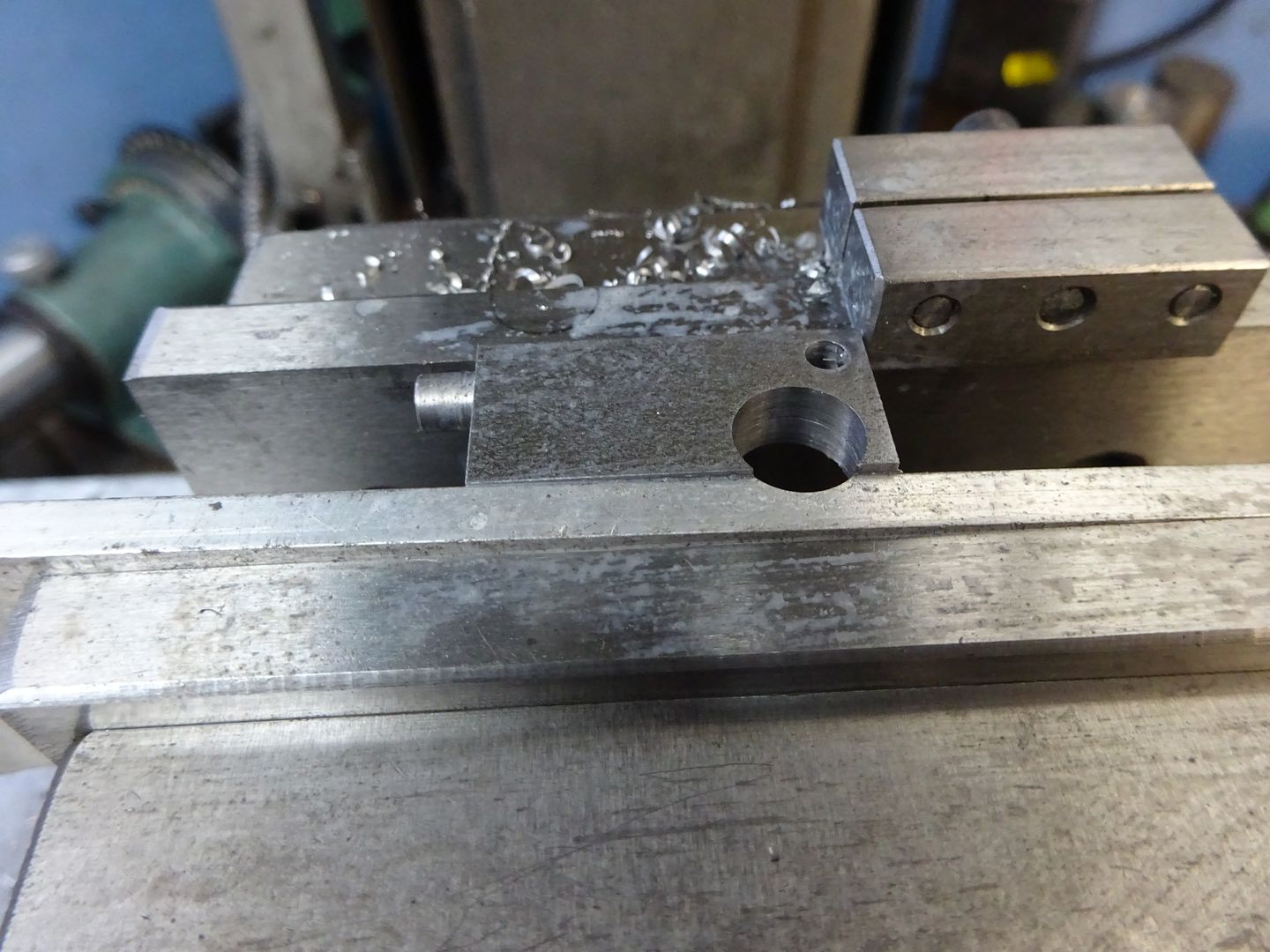

2549 forum posts 235 photos | I have turned down the shanks of milling cutters using carbide tooling. Martin |

| Thor 🇳🇴 | 11/05/2016 18:25:53 |

1766 forum posts 46 photos | Hi Ady, I assume you are saying that your collet system won't take a 1 in shank and buying a ER-40 collet system is a bit expensive for a one off job. Thor |

| Muzzer | 11/05/2016 18:37:19 |

2904 forum posts 448 photos | Are you planning to make a 7/8" (diameter surely?) hole in the block using a 7/8" ball end cutter? Or indeed a 1 3/4" diameter (7/8" radius) hole in a block that isn't even 1 3/4" wide? Doesn't compute unless I'm missing something.... Or if it's a male appendage, there won't be much of it left in the tube. Edited By Muzzer on 11/05/2016 18:38:41 |

| JasonB | 11/05/2016 18:49:09 |

25215 forum posts 3105 photos 1 articles | You say you habe a lathe so Option one is to hold cutter in the chuck ( I'll get shot down for this) and mount work on the cross slide at ctr height Option two, take a bit of 3/4" bar just over twice the length of your required cut, ctr drill both ends, cross drill in teh middle for a round tool bit and a grub screw at 90 degrees to that and cut it between centres

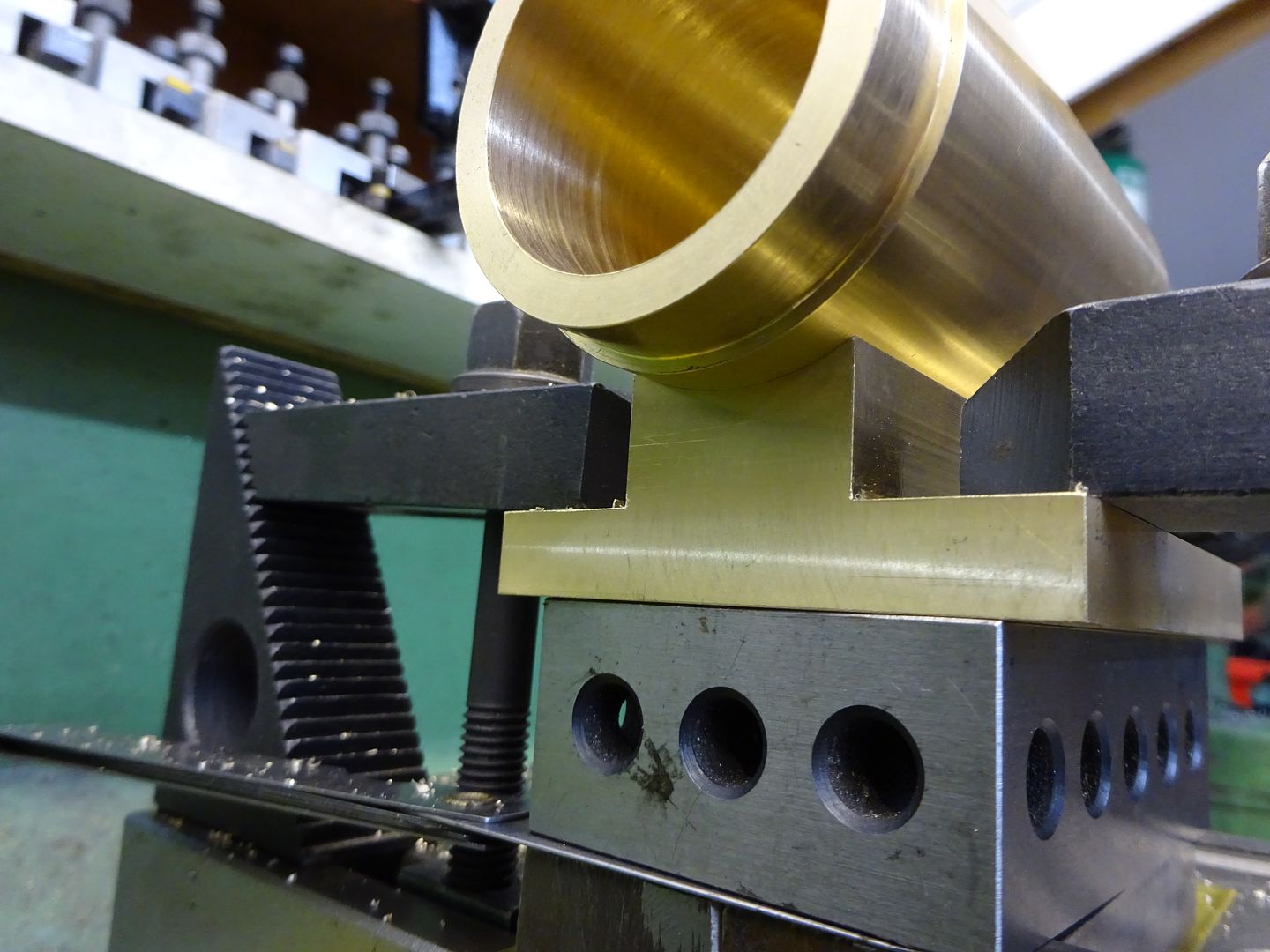

If the cut is along one of the short edges then hold it in the vice with some scrap on one side and cut a 7/8" hole with a boring bar or just drill it with a blacksmiths drill, much like I'm doing here, just position ctr of hole where you need it

Did someone mention a boring head?

Edited By JasonB on 11/05/2016 18:54:45 Edited By JasonB on 11/05/2016 18:57:21 |

| Muzzer | 11/05/2016 19:44:24 |

2904 forum posts 448 photos | Aha. There's mating and there's mating. A few better chosen words or a picture might have helped, although Jason seems to have guessed correctly. |

| Martin Connelly | 11/05/2016 20:19:10 |

2549 forum posts 235 photos | Turned down shank on a milling cutter. |

| Ady Wilson | 11/05/2016 20:45:17 |

| 41 forum posts 14 photos | Thanks for all the replies they are really appreciated. Also thanks Jason B for giving me multiple ways of achieving what I want to do. I will try to turn the shank on the cutter down as that is probably going to be the simplest option but if that fails then I think Jasons option two of cutting it with a bar between centres looks best for me to do. I have learnt some good stuff here cheers. |

| Chris Evans 6 | 11/05/2016 20:54:00 |

2156 forum posts | If you like a mathematical challenge it is possible to do with a smaller say 8mm ball end cutter. Some more modern read outs have built in assist programs for this. Me I would bore it. |

| Ady Wilson | 13/05/2016 18:30:28 |

| 41 forum posts 14 photos | Just an update I managed to turn the shank down to 20mm so I can get it in my collet chuck now. Used it and it worked out great. I wont be forgetting the tips given me though as I am sure they will come in handy in the future. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in