Electronic Artisans ELS Article

| Lester Caine | 23/03/2016 13:08:12 |

| 25 forum posts 1 photos | Rather than comment on the messages in 'Contents MEW 240' I'm starting a new thread. The stand alone Electronic Leadscrew Kit is still available, and John is still both extending it and adding other parts such as a 3D printed case, but only as time permits. Comments about the age of the project and the current alternatives are more than relevant, and there has been much discussion on both the ELS Yahoo list and other CNC lists. As an 'electronic gearbox', the ELS kit provides a nice stand alone package. It's limitations created by the 'single plus' sync also apply to other CNC options. With the arrival of a new generation of ARM based processors, interest in a LinuxCNC based solution using a higher resolution encoder are providing an alternative solution. While CNC solutions for the mill are well established, the Lathe solutions have yet to become an easy process, and ELS provides an easier path for those just needing some simple facilities, much like the DivisionMaster provides a self contained division solution. |

| Martin Connelly | 23/03/2016 13:47:59 |

2549 forum posts 235 photos | I gave the ELS serious consideration for a while. In the end I went for Mach3 running on an old slow laptop driving a Smooth Stepper via USB since I had an available laptop. If you are using Mach3 in Manual Direct Input (MDI) mode then the limitation of short CNC programs only with an unlicensed copy of Mach3 is no handicap. I also have no problem with the single pulse per revolution using a VFD driven 3 phase motor and with the lathe in back-gear. I do not need to run my machine as fast as possible since it is a hobby not a business for me. Running like that there is no perceptible change in speed of the spindle when the tool engages the workpiece even with heavy cuts. The CNC option gives a lot more flexibility than the ELS and there are easy work-arounds for the length of program limit if you do not want to spend money on a Mach3 license. Lots of experienced people can help with Mach3 if there is a problem. ELS may be harder to troubleshoot, but that is just a suspicion. Finally I was using Mach3 on my mill so knew what would be involved in setting it up and using it on a lathe would involve. Martin |

| Frances IoM | 23/03/2016 14:05:14 |

| 1395 forum posts 30 photos | Maybe being the original posterre the article I can come back - I did try to find via the Electronic Artisan and Lester's own website if the components etc were still available but couldn't see them tho there were circuit diagrams (luckily my background is here) + some software - I realised from the choice of PIC processor that the the design predated the now ubiquitous ARM processors but both web sites esp EA seem to have many noncompleted sections that date back many years (hence my comment re feeling that I felt 20years back in web sites - as a one person large website owner on a completely different topic I'm only too aware of starting a topic only to find time, knowledge + enthusiasm are lacking) My real surprise was that as Neil had pushed the article 4 weeks or so prior to seeing it in print that there would appear to have been no check on or co-ordination with the sites referenced as providing the constructional meat. I guess I could apply to join the yahoo closed group (tho I dislike yahoo) but everything seems highly distributed on the web (and I suspect now of an age where key bits are missing) |

| Lester Caine | 23/03/2016 14:19:30 |

| 25 forum posts 1 photos | http://medw.co.uk/wiki/ELS+Price+List with links to John ... All the material I have is on http://medw.co.uk/fisheye/gallery/69 archiving everything we have ... I've a lot of material archived on the MEDW site which is no longer available from the original sources. And I dislike having to log onto a forum to answer messages, so you will find me on those that provide an email interface

|

| Another JohnS | 23/03/2016 14:36:19 |

| 842 forum posts 56 photos | Posted by Lester Caine on 23/03/2016 13:08:12:

.... While CNC solutions for the mill are well established, the Lathe solutions have yet to become an easy process... I'm not sure I understand this part of your comment - can you explain further? Are you talking about turnkey solutions, or software, or... ? I'm currently machining with my little CNC lathe, and I've seen the Tormach lathe, and, if you go to the CNC Workshop in Michigan this coming June, you can join in the CNC Lathe build classes. I understand that Mach3 has design issues with threading, but LinuxCNC has been rock solid for a good number of years now. Mach4 is said to be better than Mach3, but I have not seen any evidence one way or the other - time will tell. I'll repeat my assertions - that if you go to the expense of the ELS, you might as well go to full CNC - but will state that my computer skills are "in demand" so for what (for me) is easy and natural, might not be for others, so I'm more than willing to be told to "stuff it"!

|

| Lester Caine | 23/03/2016 15:11:52 |

| 25 forum posts 1 photos | Tormach has added a layer to LinucCNC that makes it a lot easier to work with even on a mill, but it's only recently become common knowledge how we can access it.. MachineKit is working down the same path and lots of people are improving the user interface, but while simply bolting a set of motors onto a mill has been a doddle for many years, knowing just what to do with a lathe has not been quite so easy? I've been running both Mill and Lathe Mach3, but both the lathes I have on the bench here have multi-slot encoders on the head, and making use of that is only possible currently via LinuxCNC, but the 'user interface' has been waiting for the likes of 'Tormach' to provide something easier to work with. I'm finally a lot happier to go with a 'linux' solution for these lathes ... when I find some time to get back on those jobs Will John be running another batch of ELS boards ... probably not ... but the remaining stock still has a place for people who have particular jobs to do but don't want to go to a full CNC solution. Even something as simple as a manual pulse generator to automate a single axis has a place where machinists prefer working manually, and that is another use the DivisonMaster gets pressed into when it's not driving a rotary table. Not everybody is comfortable with a computer screen replacing all the knobs and are happier to pay for that. |

| Neil Wyatt | 23/03/2016 16:17:31 |

19226 forum posts 749 photos 86 articles | > I realised from the choice of PIC processor that the the design predated the now ubiquitous ARM processors Eight bit computing will never die! Neil |

| Frances IoM | 24/03/2016 11:59:01 |

| 1395 forum posts 30 photos | Lester - thanks must admit never thought of looking in a wiki for pricing etc (btw my browser reports " Strict Standards: Declaration of LibertyTag::expunge() should be compatible with BitBase::expunge() in Unknown on line 0" at top of page and image of kit results in Error interpreting JPEG image file (Not a JPEG file: starts with 0x3c 0x62) Neil - I still have an Intel 4040 + associated support chips tho suspect an interpreter of asm code on even a RaspPi would run 10x faster! |

| Lester Caine | 24/03/2016 12:18:58 |

| 25 forum posts 1 photos | Frances ... If I did not spend so much time dealing with the changes PHP makes then I would be able to add and expand the real content Trying to update everything for PHP7 and that error was missed but I've switched back to PHP6 for now |

| Neil Wyatt | 24/03/2016 16:00:17 |

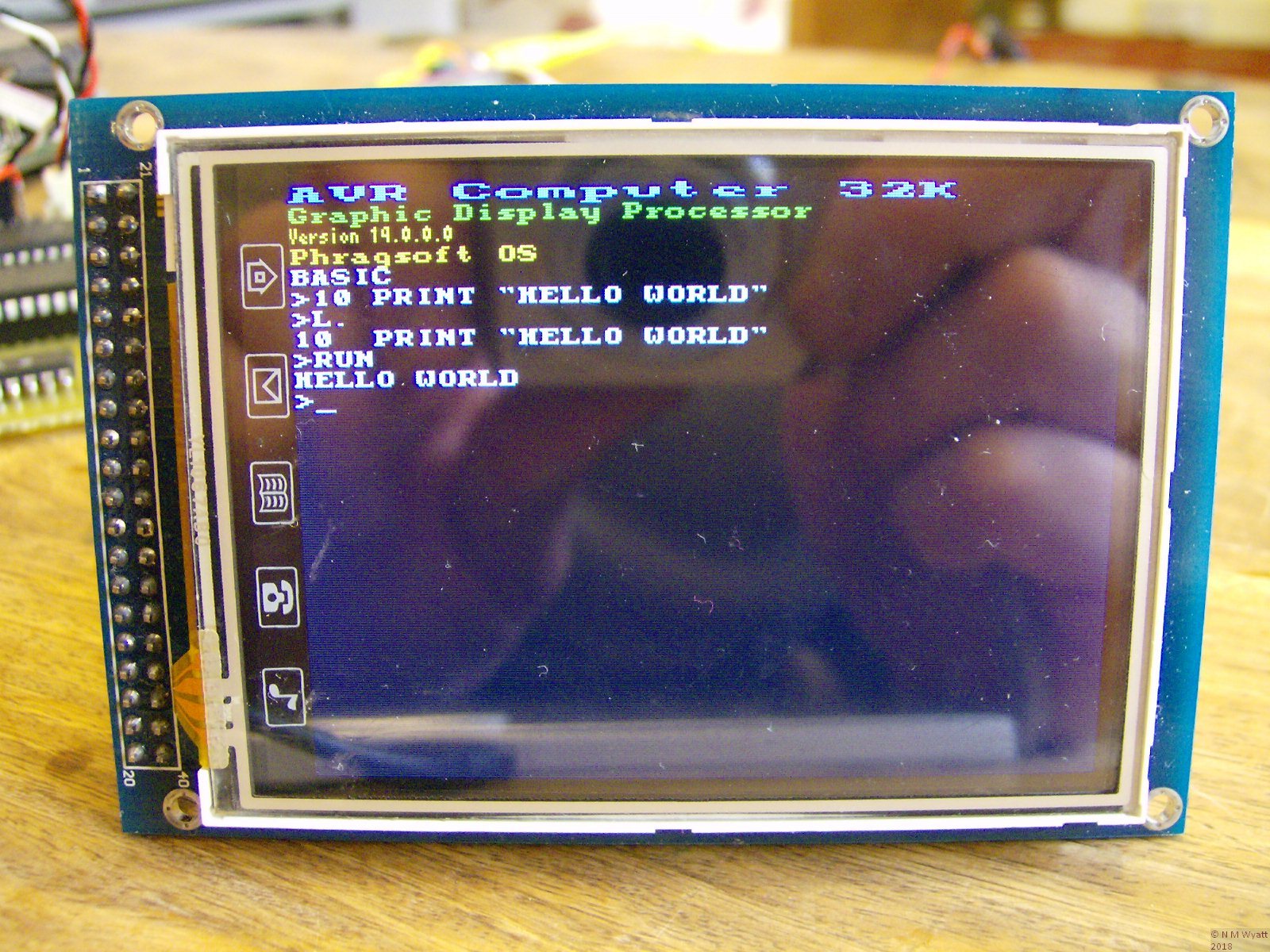

19226 forum posts 749 photos 86 articles | > Neil - I still have an Intel 4040 + associated support chips tho suspect an interpreter of asm code on even a RaspPi would run 10x faster!

Basic interpreter on 8-bit AVR: www.stubmandrel.co.uk/16-electronics/91-phragsoft-320-x-240-pixel-lcd-display-driver Some day I'll get the final version up and working again!

|

| Ajohnw | 24/03/2016 16:30:59 |

| 3631 forum posts 160 photos | I've looked at Linux CNC several times. What seems to be lacking to me is an easy intro to doing things with it. I have used Linux for a long long time and am still not comfortable with what I see concerning Linux CNC. It seems to be stuck rather high end and more pro user based than beginners. I also have a feeling that in some respects it's a bit dated and isn't capable of using a number of approaches that could be used very cheaply these days. On the other hand it uses the Linux real time kernel which is designed up front to have low latency response times - something wndows and others will probably never match. Maybe one day some group of talented people will pick it up and do something radical with it. That has happened in one other area mainly because Linux is also happy on a rasbury pi doing things a few years ago people might have thought was impossible. Actually this sort of thing only takes one rather determined individual. John - |

| John Stevenson | 24/03/2016 17:02:29 |

5068 forum posts 3 photos | Posted by Ajohnw on 24/03/2016 16:30:59:

Maybe one day some group of talented people will pick it up and do something radical with it. John - Wake up that man

Actually been discussed here before.

This is lathe but there are mill video's out there and easy to find.

|

| Ajohnw | 24/03/2016 18:38:08 |

| 3631 forum posts 160 photos | Posted by John Stevenson on 24/03/2016 17:02:29:

Posted by Ajohnw on 24/03/2016 16:30:59:

Maybe one day some group of talented people will pick it up and do something radical with it. John - Wake up that man

Actually been discussed here before.

This is lathe but there are mill video's out there and easy to find.

And sell it - actually I think that should be against the law unless they seriously contribute to open source software as well. On the other hand some commercial work mainly by the people who issue the various distro's do contribute significantly.

John - Edited By Ajohnw on 24/03/2016 18:39:02 |

| Lester Caine | 24/03/2016 18:56:05 |

| 25 forum posts 1 photos | The Tormach contributions to LinuxCNC have been substantial and we can all get at the results. It's the sort of cross cooperation that is to be encouraged. |

| Ajohnw | 24/03/2016 19:02:26 |

| 3631 forum posts 160 photos | Posted by Lester Caine on 24/03/2016 18:56:05:

The Tormach contributions to LinuxCNC have been substantial and we can all get at the results. It's the sort of cross cooperation that is to be encouraged. Where is the code ? It doesn't show up here, bottom of the page showing things that were signed off into the kernel John - |

| John Stevenson | 24/03/2016 19:04:39 |

5068 forum posts 3 photos | Posted by Ajohnw on 24/03/2016 18:38:08:

And sell it - actually I think that should be against the law unless they seriously contribute to open source software as well. On the other hand some commercial work mainly by the people who issue the various distro's do contribute significantly. John .

Actually they are wearing the white hat on this one. Many people complained over the years that Linux CNC was too complex and only understood by Linux geeks and this said nicely here .

The geeks could never understand why someone just wanted to use a machine and not play with the programming. Didn't help that it was also a committee of people. Any criticism of the program was met by "If you don't like it then the source code is available, modify it to what you want." But the people asking for this were in paragraph two and not able to. They had a workable program and therefore they were happy.

Now Tormach in the first place had hung their hat on the Mach3 tree and in all fairness it got them going and made them very successful. However later on when they brought a slant bed lathe out Mach 3 isn't capable of threading correctly without outside help and then not well. So they looked at Linux which can thread well being in real time.

Two things stood in their way. One was the abysmal screens supplied with Linux CNC and the lack of support for it.

Second one was even worse in that the trajectory planner, that's the bit that looks ahead for the next moves was badly flawed. The committee knew about this at least 2 - 3 years previously but did nothing about it.

So Tormach recruited some programmers to write a new set of screens suitable for an operator and not a programmer and sort the TP [ trajectory planner ] out which they did. Now under the open source if you alter the core program you have to give it back. The screens are an add on and not core so these could be kept as copy write and still answer the letter of the law.

The TP was different but instead of giving the code back to Linux, knowing damn well nothing would have been done with it. At their own expense they rewrote it into the latest release of Linux CNC so more than living to the letter of the law.

Expensive job but at the end of the day, no windows license and no Mach license fees. Mach 3 is dated now and no work is being done on it so it came at the right time. Mach 4 has been in development now for nearly 6 years ? as still isn't prime time so they didn't have a choice. Their business model is to sell machines, not software or programmers.

Personally I think it is something that should have happened six years earlier and it's nice to now have a product being driven by engineers for engineers instead of by geeks, for geeks. |

| John Stevenson | 24/03/2016 19:11:58 |

5068 forum posts 3 photos | Posted by Ajohnw on 24/03/2016 19:02:26:

Posted by Lester Caine on 24/03/2016 18:56:05:

The Tormach contributions to LinuxCNC have been substantial and we can all get at the results. It's the sort of cross cooperation that is to be encouraged. Where is the code ? It doesn't show up here, bottom of the page showing things that were signed off into the kernel John - John. It's not Linux per see but Linux CNC which is based on Ubuntu.

The changes that Tormach have put it are quite extensive and if you go to their site somewhere for $30 you can buy a restore disk that will restore a genuine Tormach installation. However they have to protect their investment and it's for a Tormach machine only but many people have worked out how to run it on non-Tormach machines but we are back to geeks now.

Time will tell if a non Tormach install disk will surface, the problem being who benefits with it being a non chargeable open source project.

Long short is, it can be done and has been. |

| Another JohnS | 24/03/2016 19:58:12 |

| 842 forum posts 56 photos | The Nottingham JohnS summed things nicely, w.r.t Tormach, and LinuxCNC. In the future, we'll look back in fond memory of those home workshop days "pre-CNC" akin to the way we view steam locomotives or (say) the Lancaster today. It just takes time for it all to settle in - it'll look like an overnight changeover when we look back from 2026. W.r.t LinuxCNC - one happy user here. I can fully understand why Tormach chose it as the base for their machines. Everyone knows that Engineers are lost without those pesky Human Factors people, so Tormach applied some "Human Factor" stuff to help them sell their machines. The guys at work (before the gymnasium sized workshops got moved to the other side of town) could not figure out why we'd use manual machines for making one or two parts - the link that the Nottingham JohnS posted is a good example of conversational programming. |

| Ajohnw | 24/03/2016 21:02:42 |

| 3631 forum posts 160 photos | I think there is a lot of miss understanding about Linux and software John which explain some of the problems you have mentioned. Starting at the bottom The kernel. This is the part that runs all of the basic facilities in the machine and also looks after running software at all levels. Things do have to go through a "committee" to get things in there. This is basically why it's fast. Linux cnc is based on a patched kernel that is modified to suite it's major purpose in life - cnc. A patch is just a modification to some areas of the code. The word patch signifies how big it's likely to be. There isn't much scope for mounds of code down here. The "committee" at this level are rather specialised but are mostly dealing with hardware and in some respects don't care at all what people do with it, There concern is servicing all of it without overloading the machine. Try to add something that may interfere with that and it has no chance of getting in. Sometimes there are commercial complications as well. Only one I can think of is a Philips web cam. The person who handled that actually coded the web cam and what's in it belongs to Philips so he can't really declare how it works. Then comes things that are rather like dll's but might be doing all sorts of things. Generally they will make application software easier to write. These too have a "committee" and can be a bit mixed up with the next level. That's what most people see as windows but are called desktops on linux as there are a number of them. These can stray. The aim of one that is ongoing is to make application writing even easier. Many contain graphical aspects that are similar to "dll's". The term committee has little meaning here, and not much lower down either. People come and go and are often only there because they want it to do something. Then comes application software. These are invariably written by some one who wants it as is just about all of the rest other than maybe the kernel. They come and go and often change when some one else wants something to do the same thing. People often stop maintaining things because there isn't much interest and they have done what they wanted to do. It's not unusual for a number of individuals to be working on totally different applications that are intended to do exactly the same thing. It's both the strength and weakness of Linux really and all down to people doing things that they want to do for fun, to do better or what ever. What this boils down to is that the bits you see and use in Linux CNC will have been written by some one who is into both and not really a geek at all. The problem is that there doesn't seem to be anyone around who wants to change it and in real terms there wont be a "comittee" for Tormach to submit anything to and by the sounds of it that wouldn't be to the kernel anyway. This touches on why I suggested that it's a bit dated. Requesting fixes is the same. It needs someone to come along that for some reason feels like doing the work - usually some one who wants it.

The use of Linux does annoy me at times because it's tucked away all over the place and saves companies an awful amount of time and cost yet generally they don't give anything back. A lot of software is also hijacked along with a name change and sold. John - |

| John Stevenson | 24/03/2016 21:21:44 |

5068 forum posts 3 photos | Precisely, they now have their own programmers and do not have to rely on any committee. They get a bug report then it's down to them to fix it and so far they are doing well with releases. I feel we are entering into interesting time where it 'may' be possible to port path pilot away from what It's currently based on. In which case it could exist legally as a stand alone. However it's down to them whether they want to bother. After all the few that make the journey to use it on non Tormach machines will be very small and none of them would have been a Tormach customer anyway so they have lost nothing.

Where they can move next though is the Tormach uses two cards a Mesa 5i55 and a Tormach special breakout board which is propriatory. Now the non Tormach machines can use a parallel port with reduced functions or the Mesa card but if Tormach was to buy Mesa out they would control the whole sphere and be responsible to no one.

Will that happen ? I couldn't possibly say....................

What I really wanted to say is watch the video or at least the first 12 minutes, the rest is a repeat on the other end.

Any half competent person on this forum could do what he does in the video, basically just pressing buttons. No one has this level of ease, good screens and results as Tormach have.

In two years they have gone from a clunky system only a few know how to navigate with a screen that looks like etch-a-sketch on acid to what you see in the video. They have also written the documentation for it in concise English as a book and not god know how many unrelated and unattached wiki pages that exist for Linux CNC Edited By John Stevenson on 24/03/2016 21:28:27 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in