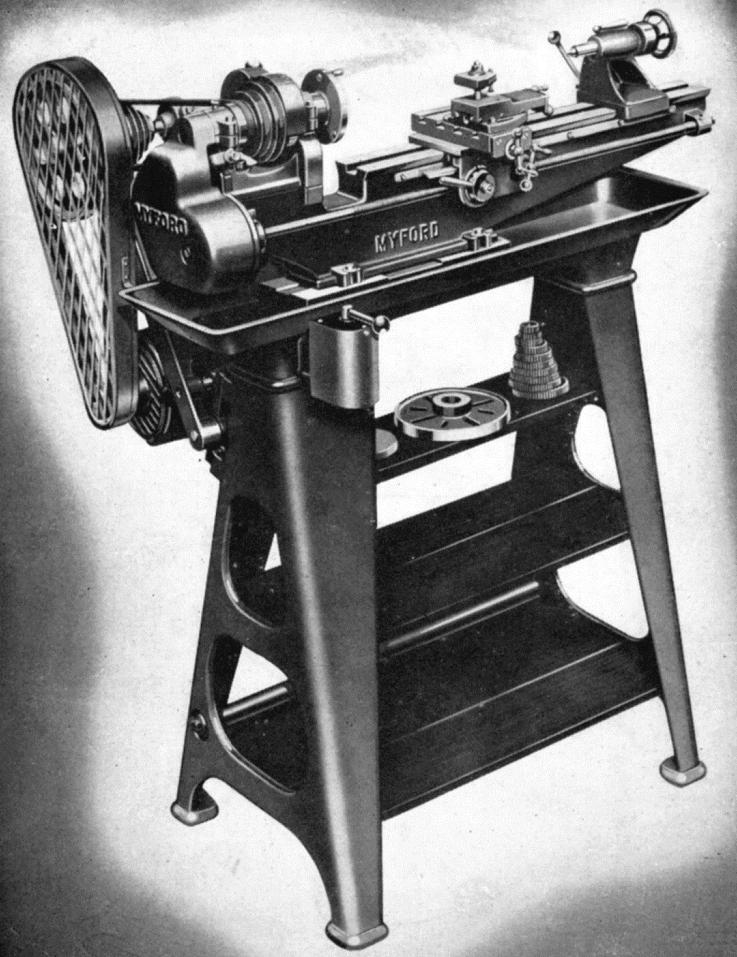

Myford ML4(?)- Headstock bearing replacement

Headstock bearing replacement

| James Woodman | 28/10/2015 17:01:37 |

| 5 forum posts | Hello, I have what I understand to be an Myford ML4 lathe, which I am currently trying to re-commission. I believe the headstock bearing is worn to excess and needs to be replaced. Can anyone advise me where I can purchase replacement bearings from and the most effective way of removing the old bearing and fitting the new? I am a complete novice- Please help. James

|

| Neil Wyatt | 28/10/2015 23:03:17 |

19226 forum posts 749 photos 86 articles | Hello James Welcome to the forum, I'll bump this for you. I'm afraid the ML4 hasn't been made for about 70 years see HERE That said, it uses a simple bronze headstock bearing and it may be possible to adjust the lathe for wear OR get a replacement made. Neil

|

| James Woodman | 29/10/2015 08:42:30 |

| 5 forum posts | Hi Neil, Thanks for responding. Are you able to explain a little about the type of adjustments? James |

| Neil Wyatt | 29/10/2015 08:50:32 |

19226 forum posts 749 photos 86 articles | Not in detail I'm afraid, but there are some folks here with ML4 experience who may be able to help. Neil |

| Roy James 2 | 29/10/2015 21:04:03 |

| 15 forum posts 9 photos | James. Could you identify your lathe type from the link that Neil gave you, it would help.? Mine has thrust bearings fitted.

james |

| Georgineer | 30/10/2015 14:26:24 |

| 652 forum posts 33 photos | Hello James, The ML2 & ML4 bearings were in two parts: 1. A thrust bearing behind the collar on the spindle nose, and 2. A pair of split bronze bushes in the headstock, with the spindle running in them. I understand that the early ML1 & ML3 had the spindle running directly in the headstock, but I presume yours isn't one of those. The thrust bearing consists of a pierced washer with ball bearings trapped in the piercings, running between two flat hardened washers. One of the hardened washers is visible behind the spindle collar; the rest is housed in a counterbore in the headstock. I turned the hardened washers over in mine to use the fresh surface on the other side. The balls were re-usable so I've not tried popping them out of their housings to replace them. End play can be adjusted with the threaded ring at the other end of the spindle - don't forget to slacken the grubscrew. If the ring is too stiff to turn, drop the grubscrew out and temporarily screw in a longer bolt to give good leverage. It avoids getting mole-grip marks on the ring. The bronze bushes can be adjusted with the bolt which straddles the split in the front of the headstock casting, and I would strongly recommend using this adjustment to see if you can get the lathe good enough for your purposes. The bearings are very sensitive to this adjustment, and a tiny part of a turn is enough to go from too-sloppy to too-tight. Whatever you do, don't over tighten it or the casting will go snick! and your lathe will never be the same again (you wouldn't be the first). If the bronze bushes are beyond adjustment, I imagine your only hope is to make new ones. Myfords still had them available in 1971 for less than a pound, but I fear they have sold them all by now. I've not had to do it, but would drive out the old ones using a shaped drift to avoid damage, make new (including oil grooves) and drive in. On second thoughts, I might make a puller with a shaped end piece and draw the bushes out and in with a biggish fine-threaded bolt through the middle. In a perfect world the bores of the new bushes would be slightly undersize, so they could then be line-bored in situ. George |

| James Woodman | 30/10/2015 15:24:36 |

| 5 forum posts | Hi James, It is the ML4:

|

| Michael Gilligan | 30/10/2015 17:04:12 |

23121 forum posts 1360 photos | James, Not sure how much it will help, but here is a reasonable picture of the ML4 bearings [from a 'sold' ebay item]. MichaelG. |

| bodge | 31/10/2015 02:57:24 |

| 186 forum posts 3 photos | Hello James Re headstock bearings, click Neils link, click archive at top of page, click Myford, click 4inch precision , scroll down 21st pic down shows similar type headstock bearing to the ML4 and short piece of text . I dont know if the hard wood strip was ever used on the ML4 bearings. it would be a worth while mod though. The idea being lessens the risk of snapping the headstock casting. bodge |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in