Compound Slide Locks

| Alan Rawlins | 10/06/2015 11:50:25 |

| 74 forum posts | Are all lathes supposed to have a Compound Slide lock on them? Mine doesn't have one but, it does have one on the Carriage Slide. When I asked the question of the Distributors in the UK about this I was given the answer that the lock on the Compound slide was only for use during transportation. Also he said that if the compound slide was moving when using it to machine across the face of something, ie at 90 deg to the bed, The cutting tool wasn't the correct shape or was blunt. What do you all think? As the Operators Manual is what is known as a generic manual, I guess they mean it covers different lathes and sizes of lathes. My manual that I have shows a picture of the Compound Slide lock but, it is for a different machine to mine. My lathe is of the Chinese variety. Overall it is a good lathe apart from mistakes in the manual. |

| Martin Kyte | 10/06/2015 12:04:46 |

3445 forum posts 62 photos | I did the (George Thomas?) mod on my Myford which adds a Locking screw with a little lever knob between the gib adjustment screws on my compound slide. I allows me to lock the slide without changing the setting of the gib and does give a little more resiliance to the tool post. regards Martin |

| Capstan Speaking | 10/06/2015 12:20:36 |

177 forum posts 14 photos | A small Chinese lathe probably isn't made to have one. Judging by the spin on the situation you were given I can guess which that company is. If you use the compound handle to take up the backlash you will probably not even miss a clamp screw. Mini lathes are so small that the tool can push off when facing by pushing the saddle back. I just drop the screwcutting lever on a stationary leadscrew. |

| Harry Wilkes | 10/06/2015 15:27:26 |

1613 forum posts 72 photos | I too fitted George's mod on my S7 and have found it very useful !! H Posted by Martin Kyte on 10/06/2015 12:04:46: I did the (George Thomas?) mod on my Myford which adds a Locking screw with a little lever knob between the gib adjustment screws on my compound slide. I allows me to lock the slide without changing the setting of the gib and does give a little more resiliance to the tool post. regards Martin

|

| Bazyle | 10/06/2015 16:58:50 |

6956 forum posts 229 photos | Most small / hobby lathes don't have cross slide or top slide locks and never have had. Even saddle locks are not universal. Mostly people found they didn't need them, or when they did they just made an extra hole or used one of the existing gib holes. Don't think many amateurs were ever prepared to pay the extra for fripparies they could add themselves for peanuts. |

| Neil Wyatt | 10/06/2015 19:21:55 |

19226 forum posts 749 photos 86 articles | As Bazyle says - they are a rare breed on lathes though usual on milling machines. That's because in normal use most cuts are applied in directions unlikely to cause a slide to move unexpectedly. Most people who worry about such things just nip up a convenient gib-screw, or like GHT and his Myford, they add one. The minimum you need is a suitable tapped hole and a screw with a neat end on it. Neil |

| JasonB | 10/06/2015 19:30:18 |

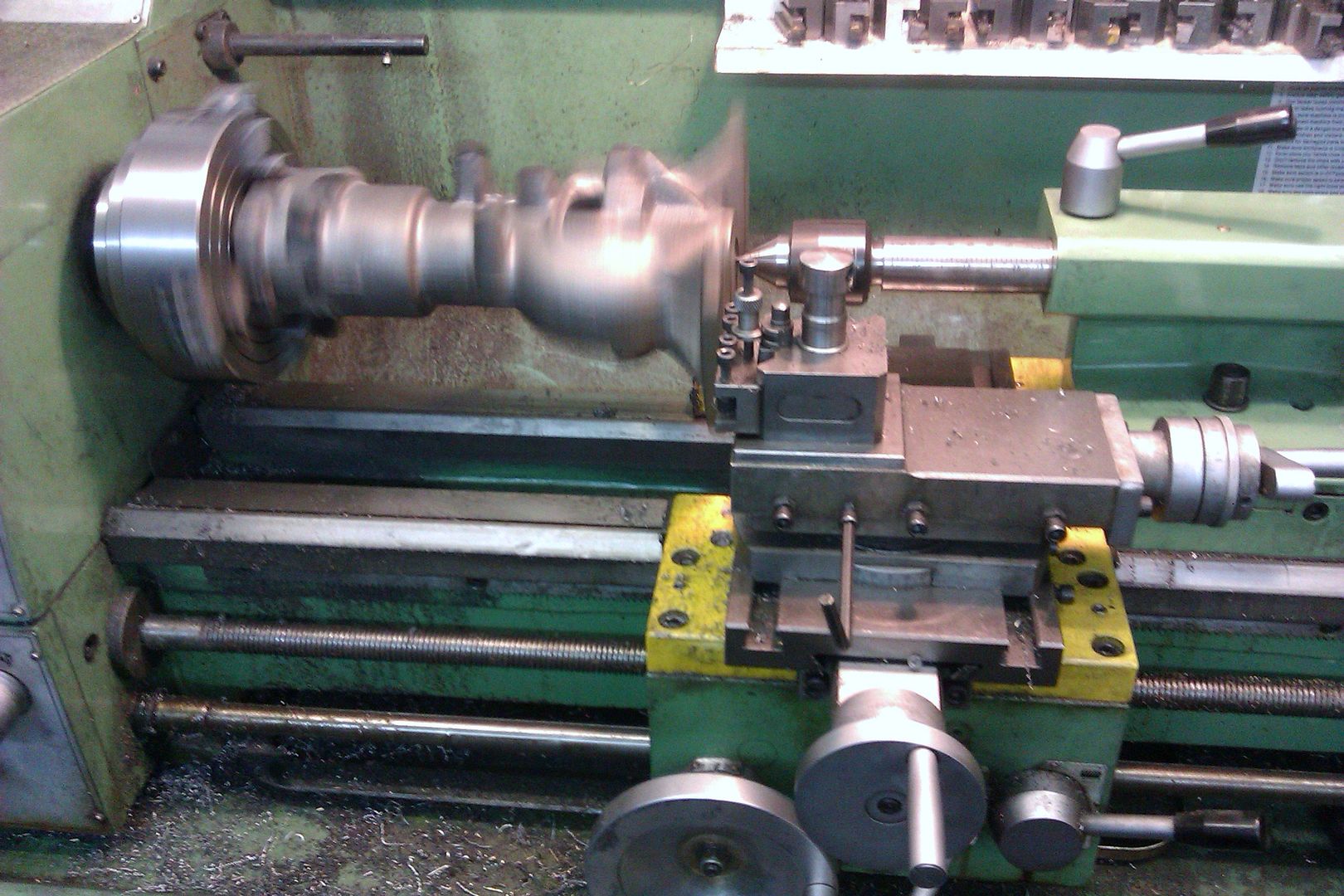

25215 forum posts 3105 photos 1 articles | Quite a few of the far eastern lathes will have say three gib adjusting screws with lock nuts and one screw without, this one can be nipped up with an allen key when required, mine does on both the cross and compound slides. My Austrian Emco before was the same. Your WM250 should be exactly the same as my 280

J

Edited By JasonB on 10/06/2015 19:56:29 |

| Alan Rawlins | 10/06/2015 19:58:47 |

| 74 forum posts | Again, thank you to all, for your responses. I think I will try JasonB Idea, as he says, mine is the same as his. |

| Versaboss | 10/06/2015 21:50:30 |

| 512 forum posts 77 photos | Speaking of compound slide locks - do you think al lock in vertical direction, pressing on the non-guiding part of the stationary slide, is a viable idea? Reason is on my lathe I installed a Chinese scale on the front of the topslide, and now the adjusting screws are partially hidden and there is not enough room for a lock screw between the scale and the slide. I hope this description is sufficiently clear to see what I mean. If that's a bad idea, why? Regards, HansR. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in