Help with a myford lathe??

| Harry Batchelor | 18/03/2015 15:46:55 |

| 7 forum posts | Hi, I recently purchased a Myford M lathe and was hoping someone might be able to tell me the very basics on using. At the moment I can't even figure how to turn it on! It's in my garage and I can't move it and dont have power there yet, will it run off a petrol generator? How do I start it up? Thanks in advance.

|

| Tim Stevens | 18/03/2015 17:40:05 |

1779 forum posts 1 photos | I wouldn't try connecting to a generator, not yet. You need to work out exactly what you have got. If it is an ML7 - the M type most general for metal turning - there should be an electric motor fixed at the left of the machine, and at the back. The body stands on four cast-in feet. The motor should have a v-belt driving a bigger pulley on a shaft with a three-pulley cone, and another belt to the main spindle. Before you turn anything on, you need to check that the motor turns (by hand), and that when it turns the pulleys and the main spindle also turn more slowly, but without anything catching. Before you start it, you also need to have it bolted down securely and level, or damage is likely to be caused. Why not have a look and see if there is further information on the machine, and we might be able to help further. A photo or two would be wonderful, too. Cheers, Tim |

| Harry Batchelor | 18/03/2015 17:50:22 |

| 7 forum posts | Hi Tim,

Thanks for taking the time to reply. I'm not even sure what model it is - perhaps an 'M' Type post Drummond? Or ML2/4. I've added some pictures below. As you will see from the pics it has a 3 pin 240v single phase plug but this goes straight into the motor there is no on/off switch? I just want to check it is running okay and sell it on to be honest as I wont use it, and want it to go to someone who will get use from it. It seems a shame to leave it sitting in my garage.

Edited By Harry Batchelor on 18/03/2015 17:54:32 Edited By Harry Batchelor on 18/03/2015 18:11:44 |

| frank brown | 18/03/2015 17:52:49 |

| 436 forum posts 5 photos | Big thing, has it a 13 A plug on a lead?, if so no big problem, you will need a generator of at least 1KW to start it but the running power will be lower. If its got a three core mains lead, then if you recognise the colours, then fit a 13 A plug and go. If its got a four core lead then the motor in the machine is for three phase and will not plug and play with domestic mains. If there is no lead, then trace any cable coming out of the motor, it should go to some sort of switch, which if you are lucky will be labelled forward, stop and reverse. Would be a good opportunity to turn the motor by hand and see that the belt moves OK and likewise the chuck. it would be a shame to power up the motor if any of the shafts in the lathe are seized. Frank |

| Harry Batchelor | 18/03/2015 17:56:21 |

| 7 forum posts | Thanks Frank. I've turned the motor by hand and all belts turn. Just strange there is no switch. I'm pretty sure it is a standard 3 core plug which is fitted. |

| Neil Wyatt | 18/03/2015 17:57:48 |

19226 forum posts 749 photos 86 articles | You can embed photobucket pictures using teh advice here: www.model-engineer.co.uk/forums/postings.asp?th=103028 Neil |

| Thor 🇳🇴 | 18/03/2015 17:59:16 |

1766 forum posts 46 photos | Hi Harry, Have you checked out Tony's lathes.co.uk site? You will find information on Myford lathes here, you should also be able to get a manual from Tony if you don't already have one. If you want an introduction to using a lathe, have a look here. Thor |

| Tim Stevens | 18/03/2015 17:59:39 |

1779 forum posts 1 photos | What a jolly looking - but quite old - device. Not ML7, but perhaps a relative? Where are you, Harry? Cheers, Tim |

| Harry Batchelor | 18/03/2015 18:08:25 |

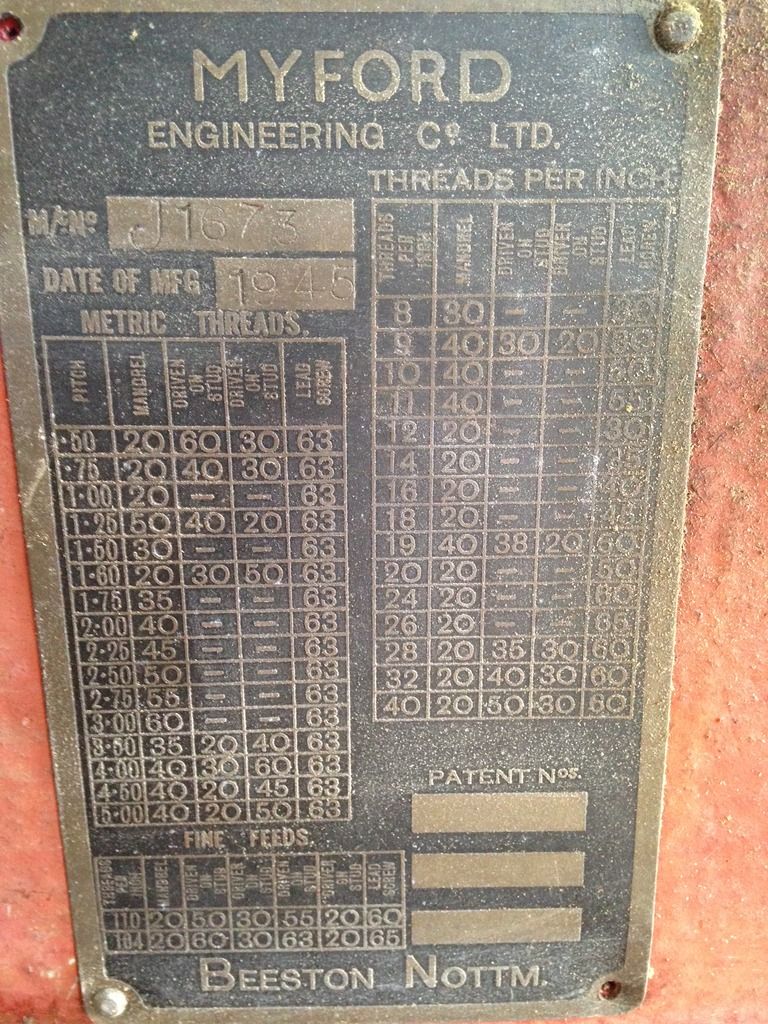

| 7 forum posts | I have looked on lathes.co.uk and emailed Tony earlier this week. There is very limited info on the 'J' serial number, it is either a Myford 'M' type or an ML2/ML4 but i'm not sure. I'm down in Sussex Tim. The lathe is (or will be) for sale - as soon as I can test its functionality! Thanks all. |

| Eugene | 18/03/2015 18:10:56 |

| 131 forum posts 12 photos | Harry, There is also a Yahoo internet group devoted to Myford / Drummond lathes and the M type has a large following there with lots of information. Depending on condition, tools supplied, equipment and specification they sell on E-Bay from about £75 for a rust ridden wreck to £450 -500 for a pristine well equipped model on a stand. Regards, Eug

Edited By Eugene Molloy on 18/03/2015 18:20:17 |

| Harry Batchelor | 18/03/2015 18:12:59 |

| 7 forum posts | Pics now above. Anyone got any ideas on on/off switch!?

|

| Tim Stevens | 18/03/2015 18:21:31 |

1779 forum posts 1 photos | All you need, I think, is an extension lead with a switched outlet. Best to have the switch handy to the lathe and not three rooms away. Please apply lots of oil to everything that can move before you switch it on. And let me know how much and I will work out how to get to Sussex. I'm in mid Wales Cheers, Tim |

| Bazyle | 18/03/2015 18:25:30 |

6956 forum posts 229 photos | It looks like a Drummond stand and Drummond M type tailstock but Myford ML motor mount so it might have been hybridised a bit in its life. Hunt around this site until you identfy it. |

| Bazyle | 18/03/2015 18:34:43 |

6956 forum posts 229 photos | Posted by Harry Batchelor on 18/03/2015 18:12:59:

Pics now above. Anyone got any ideas on on/off switch!?

What's all this fuss about a switch? Loads of things don't have a switch. The EU regulation that requires everything to have a switch (unless it has a standby mode of less that 0.5W) was only brought in about 2007 and I think we can all safely agree this was built and first sold to the public a bit before that. (yeah yeah when the new owner sorts it out they can put an emergency stop on it) |

| Harry Batchelor | 18/03/2015 18:41:14 |

| 7 forum posts | Ok, thanks for all the help. Will have a further play with it this week and see if I can't kill myself. Then it'll be on eBay I expect. Wish me luck. |

| Eugene | 18/03/2015 18:42:46 |

| 131 forum posts 12 photos | Anyone got any ideas on on/off switch!? Harry, The M Types were originally equipped with a rotating switch known as a "Dewhurst". They are a safety hazard and many M Type users have binned them and just rely on the wall switch. If you are selling on I suggest you do the same for testing purposes, but point out to purchasers that they should ensure their own electrical safety arrangements through a professional electrician. From the pics I can confirm it's a standard size Myford M Type, complete with the original Norman patent tool holder, countershaft, tailstock and belt guard. 1946 was just about the end of the production run. I don't think the stand is contemporary, it looks to be from an earlier time when these machines were foot driven, a bit like an old fashioned sewing machine; not that it matters much. The red paint is a later addition too. Apart from change gears and chucks, the other significant missing bit is the cast iron cover for the gear train. As, when and if you sell it, advise anyone disassembling the machine for easy transport to be very careful with the cast iron motor plate unit; it's dead easy to snap it. Eug

Edited By Eugene Molloy on 18/03/2015 18:46:33 Edited By Eugene Molloy on 18/03/2015 18:53:19 Edited By Eugene Molloy on 18/03/2015 18:57:29 |

| Harry Batchelor | 18/03/2015 19:00:16 |

| 7 forum posts | Thanks Euqene - Top info! I think I have all the missing parts you mention in a crate which also numerous tools, cogs, etc... there's a whole crate full of accessories for the machine. Any idea on value in current state if it runs? |

| Eugene | 18/03/2015 19:15:39 |

| 131 forum posts 12 photos | Even if the motor doesn't run, if the spindle runs free, and all the other bits are present and correct, around £300 - 350, but bear in mind that like a lot of things this stuff is worth what people want to pay. Eug Edited By Eugene Molloy on 18/03/2015 19:26:37 |

| KWIL | 18/03/2015 20:55:10 |

| 3681 forum posts 70 photos | Frankly its a museum piece and thats where it should be |

| V8Eng | 19/03/2015 08:52:19 |

| 1826 forum posts 1 photos | There's a lot of people out there using museum pieces on a regular basis, most of them refitted, tidied up and made safe. I know of a town museum that has a round bed Drummond on permanent display, not read anyone on here describing those as museum pieces though! As an aside: I think that to comply with UK electrical regulations, motors above a certain power need to be fitted with No Volt Release systems, perhaps one of the electrical guys on here can advise? Edited to correct auto spell correction. Edited By V8Eng on 19/03/2015 08:56:31 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in