Small saw. Proxxon or something else

| SillyOldDuffer | 23/04/2021 16:39:06 |

| 10668 forum posts 2415 photos | Posted by John Smith 47 on 23/04/2021 14:46:44: ... ... I meant "as close to exactly 45° as one can reasonably hope to obtain in a home workshop without undue time, effort and pain..." moreover I did subsequently clarify that I needed my 45° chamfer to at least be within 1 to 1.5 degrees The wavelength of light is about 0.5 microns so no, I don't literally mean within the wavelenght of light, I meant that when you polish the surface there is no obvious bending in the plate near the cut that has been caused by the cutting process. ... Like Michael, I'm confused by some of John's terminology. I suggest it's best not to use engineering specific terms in an ordinary way because it might confuse engineering savvy readers. For example, 'EXACTLY 45°' strongly implies high-precision, which is achievable in a home workshop, making the clarification 'as one can reasonably hope to obtain in a home workshop without undue time, effort and pain' unhelpful too. Especially when we find the actual requirement is 'within 1 to 1.5°', which isn't particularly exact at all. Worth trying to express problems accurately, even though it's so difficult to do. Pays to be precise, numbers preferably, because the requirement can have a big impact on the tools and techniques needed to meet it. Really bad to be advised to buy the most expensive kit on the market when something ordinary would have done, and equally bad to be told a basic tool will do the job when it won't! Considering mirror-like surfaces, it's the difference between:

John's redefinition of optically flat still leaves me in the dark. I'm not sure if he's after an optically good mirror for imaging or a straight edged reflector for cosmetic reasons. Depending on how good the edge needs to be sawing with sacrificial support underneath might be good enough. However, I'd probably make the plate by cutting it oversize with a saw or nibbler and then milling, filing or grinding the edge to size. Two processes, one fast and crude, the other slow and delicate to remove cutting damage and get dimensional accuracy. Excellent work can be done with simple tools. It requires skill and patience, and maybe one has to ignore an overflowing giant scrap box! When time is of the essence it pays to cough up for the best tools available and make jigs etc. Otherwise, most of us use the best tools we can afford, which are rarely top-end. My machines are relatively crude, underpowered and lack rigidity. But they mostly do what I need eventually, provided I drive them carefully, practice, take advice and think! In my world Model Engineering is one compromise after another. Dave

|

| Pete. | 23/04/2021 16:41:34 |

910 forum posts 303 photos | Posted by John Smith 47 on 23/04/2021 14:46:44:

@Pete - I know that there will always be a little bit of finishing required. But what's the thinnest sheet you have cut this way and had it come out without being bent? I am working with magnets and even the slighest bed in the steel sheet is completely unacceptable. These bends only become evident when you try to sand/polish the steel. Yes I tied a nibber - manual one used extremely carefully - and the results were completely unacceptable. John, I don't know where a nibbler came into the equation? The shear I showed cuts without distortion either side of the cut, this is for roughing out a few millimetres oversize, the shear can be used for trimming the edges, you could finish it as you already have been doing, some emery cloth on a flat surface to de burr the edges. I've never used it with under 0.9mm sheet steel, never had any need, I thought your request was primarily for 1mm steel and stainless. You can actually cut surprisingly straight lines with a piece of angle iron clamped to the sheet, using it as a straight edge to guide a 1mm slitting disc on an angle grinder, I use this method to fold sheet, as 1.5mm sheet steel is incredibly harder to bend than 1mm, without any folding equipment in my small workshop, by slitting half the thickness it allows very straight sharp corners to be bent without the proper equipment, then stitch weld the inner corner to replace the strength. I need to fabricate some drawers for my lathe cabinet soon, so I could demonstrate this for you, but I'm so busy I won't get a chance for a few weeks

|

| Dave S | 23/04/2021 16:56:38 |

| 433 forum posts 95 photos |

My surface grinder is supposed to run 71/2” wheels iirc, so I didn’t look at that. However:

Homebrew cutter grinder: Has a 4” cup in it currently, also runs a 4” saucer. Speed: Also just under 3000 rpm. I have never needed to run a slitting disk on either, but I don’t doubt that with a thin wheel at that speed both would still work. Of course it would need to be the right wheel. Abrasive wheels are cutting tools, and much like different types of carbide or HSS there are different types of wheel. A wheel designed to run at 10000 rpm is built differently to one with a slower maximum speed. I do wonder if John S is trolling or just indecisive.

Dave |

| Pete. | 23/04/2021 16:59:01 |

910 forum posts 303 photos | Sorry I forget to add, 18v shear for roughing out, bench shear for trimming edges to finished size, incase it might have caused some confusion. |

| JasonB | 23/04/2021 17:44:52 |

25215 forum posts 3105 photos 1 articles | John, regarding drilling, in the other thread I said they do a sensative drill attachment which is ideal for small holes and allow the drill to be raised and lowered quickly to clear swarf etc. You can buy similar over here that will fit for a lot less. As I have said from the start a mill with slitting saw will do the job I just stuck a bit of manky 0.8mm, 110mm long mild still in my mill and mounted a fine tooth HSS saw blade. First cut is leveling off the top second is cutting a 1.5mm wide strip. Any bend you see is due to the parent metal being from the scrap bin and not flat to start with. If cleaned up it would Look flat which is what I expect you mean as you don't want deformed edges like a shear can gibe or curled parts like tin snips. Could not get the phone to focus well but once the small burr was knocked off it would clean up well with a quick rub. A more concentric blade would probably help too! |

| John Smith 47 | 23/04/2021 18:47:26 |

| 393 forum posts 12 photos | @SillyOldDuffer I am working with magnets and need to transfer the maximum possible magnetic flux between surfaces. As you may know, much like electrical current, magnet flux doesn't like jumping big gaps. Yes as noted, sacrificial support would help. If strong enough it would help perfectly but would slow down the cutting speed, and generate a lot of cuttings. Like I say using a nibbler was an absolute disaster, with the bending of the 1mm steel extending for a good mm or so, even on 1mm mild steel plate. A hacksack does not bend the plate but I find it painfully hard to cut long distances very straight - I just want a machine to help me. Can I just say it needs to be flat to within 1 thou and move on?

Also - to get clear a "Bench Shear" is basically a guillotine with a long arm for leverage, yes? [I am a newbie, please remember]

But given those numbers, can you explain why are all the circular table saw manufactures are all so adamant that their machines can't cut steel? If just don't make sense... > I do wonder if John S is trolling or just indecisive. @Jason B - awesome video! I agree a good quality mini milling machine would solve a lot of problems. What would you say is the thinnest thickness of mild/stainless steel you could do that treatment with?

|

| JasonB | 23/04/2021 18:57:37 |

25215 forum posts 3105 photos 1 articles | Posted by John Smith 47 on 23/04/2021 18:47:26:

@Jason B - awesome video! I agree a good quality mini milling machine would solve a lot of problems. What would you say is the thinnest thickness of mild/stainless steel you could do that treatment with? I would not want to go much below 0.5mm without additional support, with it sandwiched then I don't think your 0.1mm would be a problem. Will see what I have to try it on tomorrow. |

| Pete. | 23/04/2021 19:23:22 |

910 forum posts 303 photos | John, I wasn't suggesting you buy one, I just said that's what I would use to rough it to shape without distortion before using the bench shear, it's used freehand so won't produce you precision straight edges. A small mill is the ideal tool. |

| Dave S | 23/04/2021 19:41:49 |

| 433 forum posts 95 photos | @Dave S - Cutting with a grinding disk is grinding I have some thin wheels for my surface grinder, which IIRC runs at a similar speed in terms of rpm. It’s surface speed is slightly more, as it has bigger wheels when new.

But given those numbers, can you explain why are all the circular table saw manufactures are all so adamant that their machines can't cut steel? If just don't make sense... Product liability would be the first thing. If I designed a machine to use a course toothed saw to cut wood which is fairly soft I wouldn’t say it could cut metal which isn’t - that would lay you wide open to claims for failure. Cutting metal generally involves higher forces, and most tools are built with cost as a major consideration. All then”cheap” table saws I’ve seen have pressed tables and large gaps around the blade. Not what you want for cutting thin bendy stuff. Wood at least will destruct as it tries to wedge into the blade / table gap.

As I said somewhere in one of your threads the best decision, especially if you are up against a deadline, is to make one. So far I have seen something like 4 threads where you jump off into another line of investigation without having seemingly actually done anything with the information from the previous ones. You have impossible yet also imprecise specifications and don’t seem to listen when people say you can have that, but this compromise applies - usually it’s because you seem to want a Rolls Royce but only pay Robin Reliant prices or some other unicorn fantasy. You might be better to sub contract your machining, you won’t get new toys to play with, but your device could be finished. That would however mean properly specifying what you actually want and I’m not sure you know this. |

| John Smith 47 | 24/04/2021 01:55:21 |

| 393 forum posts 12 photos | > Cutting with a grinding disk is grinding I would have thought that during grinding it may be important not to change any heat treatment of the metal... e.g. when sharpening a knife say. Whereas cutting - e.g. with a angle-grinder - seems like a more brutal process. From what I can see 4.5" (115mm) and 9inch (230mm) angle grinders seem to run unbelievably fast even the large ones seem to run at 6000RPM, smaller ones more like 8000RPM. I would have guessed that if you want precision a slow speed would help. But if you want precision and the ability to cut fast, then an extremely high speed would also help. ...But what do I know? @Dave S I thought we were here to discuss 'workshop tools & tooling'... but since you ask, yes, various deadlines have now passed... with more to follow. So far I have been making do with fine-toothed hacksaws, good quality course file and a fine file, and various grades wet & dry, sometime mounted on flat blocks of MDF. Once cut I have 'sanding' them down using customised small stick-like piece of wood (or sometimes finger) with double-sided sellotape (which works BRILLIANTLY, btw). The problem is that it's extremely time-consuming as well as demanding great skill & concentration... and all trying to do manually what a machine could do much more accurately. At some point soon we will need to move to small-scale production of our products and that will definitely necessitate better tools. But we are poorly resourced and without a permanent workspace and I need to be extremely careful with finances and use of space. Yes, some stuff I have outsourced - some machining and some laser-cutting - but it as you can imagine it always has a relatively slow turnaround time and a large cost, particularly the setup cost. And before you can blink you soon find that what you've ordered isn't quite what you actually want! I have flagged from the top, and repeatedly, that I am a newbie to all this. It is precisely because I am listening - intently - to all new information and opinions that making making decisions has proved hard. "Any damned fool can make poor decisions" and make them as fast as you like! If you want the truth, I have felt honoured and delighted with all the high quality contributions from model-making experts in this community tolerating my various dumb questions, not that their opinions always match each other - we all have our individual biases & preferred ways. However until now, I have been assuming that if any contributors to this thread no longer find this thread interesting... that nobody is "forcing" them to read any of this stuff. If this is not the case please do let me know. Edited By John Smith 47 on 24/04/2021 01:57:52 |

| Pete. | 25/04/2021 00:58:09 |

910 forum posts 303 photos | usually it’s because you seem to want a Rolls Royce but only pay Robin Reliant prices or some other unicorn fantasy. You might be better to sub contract your machining, you won’t get new toys to play with, but your device could be finished. That would however mean properly specifying what you actually want and I’m not sure you know this. I'm not sure, John's toughest requirement in my eyes were the seemingly ridiculous weight/space restrictions for metal working equipment, the space restriction being absolutely none, I got the impression he was willing to spend good money for the piece of equipment that would meet his requirements. In this thread John, everyone has suggested things that could be made to work, to make parts of what you want, a shear could work, but it wouldn't grind you 45° edges, a table saw type machine like the proxon with an abrasive cut off disc could cut your metal, but it wouldn't grind your 45° edges accurately. A small milling machine is the obvious thing that could achieve your goals, a hss slitting disc, a small abrasive disc for cutting your parts, you could mount small grinding wheels combined with a tilting vice to finish your edges at desired angles, it would do pretty much everything you need. The new model sieg x1 sold by Arc euro advertising at the top of this page, has a fixed column, 4 screws, as I said to you in another thread, this machine weighs 50kg, if you remove these 4 screws you could meet your requirement of being able to move two 25kg parts from the dining room table to the side cabinet when not in use, I believe this was your requirement, it costs about £600, is in stock from a UK supplier. |

| Stuart Munro 1 | 26/04/2021 07:59:29 |

| 108 forum posts | Cutting sheet metal accurately is such a fundamental component of model engineering that I've enjoyed this instructional debate. If only some enterprising manufacturer would pay heed and design something that works - I'm sure many of us would buy it. John and myself to start with. Now the (long retired) corporate/financial analysts in me comes out. Jim Byrnes in Florida and Sherline in Australia were modellers who decided that the machines they wanted were not being made...the rest is history. Anyone out there with a business plan? Just dreaming, as I do of owning a real lathe and mill. Alas, my /Sherlines are all I have room for. Stuart

|

| SillyOldDuffer | 26/04/2021 09:29:46 |

| 10668 forum posts 2415 photos | Posted by John Smith 47 on 23/04/2021 18:47:26:

@SillyOldDuffer I am working with magnets and need to transfer the maximum possible magnetic flux between surfaces. As you may know, much like electrical current, magnet flux doesn't like jumping big gaps. Yes as noted, sacrificial support would help. If strong enough it would help perfectly but would slow down the cutting speed, and generate a lot of cuttings. ... Can I just say it needs to be flat to within 1 thou and move on? ...I am guilty! Though in mitigation the forum does tend to wander off the subject! I thought we'd moved away from the magnet problem (which I also misunderstood at the get go), and where discussing the properties of Proxxon type tools in general. I don't believe any of the Proxxon tools will do the magnet job in a single operation. Worse, I can't think of an affordable general-purpose machine that would do it either! Expensive machines yes. All is not lost. The job can be done in steps, in this case two:

Making parts in several stages is the usual way things are done. Here, the workflow might be:

If many blanks are to be finished, it's worth making jigs to hold them. Rather than carefully positioning each blank in the vice, instead drop them into a fixed jig that guarantees position and accuracy. Making jigs is a lot of trouble, usually not worth doing unless tens of identical parts are needed. I think it's do-able with a Proxxon saw AND a Proxxon Mill, even though neither are entirely happy cutting steel. Worth repeating: John's price and space constraints make this a difficult challenge. Industry could produce these for a fraction of a penny, but their method, probably involving grinding, is expensive to set up. They might charge £10000 to make one, and then knock out the next thousand for a quid! Dave

Dave

|

| Nicholas Farr | 26/04/2021 17:15:42 |

3988 forum posts 1799 photos | Hi, it seems to me that not many people want a table saw to cut steel with such precision, being there doesn't seem to be any budget machines about, and I doubt one would be very cheap. Cutting any metal by mechanical means, will introduce a certain amount of distortion and the thinner it is, the easier it is prone to distortion. Industry probably has machines, but of course they will be used for mass production and therefore the cost of them would be viable. I don't know exactly how flat the OP wants his thin steel or what width and length he is after. I've cut this piece of 0.004" (0.1016mm) from a rolled up shim steel stock, with a decent pair of scissors and have only wiped a smooth file over the edges to remove any sharps. It is 30mm wide and 115mm long and both sides have been cut. I'm not claiming that the sides are absolutely straight or that it is absolutely flat and the distortions that can be seen is where it has been straightened between my figure and thumb, even at this thinness, you can distort it just by handling. I think JasonB's idea of clamping between two pieces of wood and cutting with a slitting saw on a milling machine would be the best bet, even if the cut was slightly wider and then clamped between two pieces of wood in a vice, so that just a small amount is sticking out, to enable it to be filed to size. So without expensive machinery, there is not really a mass production method. Regards Nick. Edited By Nicholas Farr on 26/04/2021 17:18:47 |

| Stuart Munro 1 | 26/04/2021 17:41:13 |

| 108 forum posts | Nicolas, I think that I already mentioned that I cut aluminium and brass sheet with sheers then file to a smooth straight edge - like your example above. My one refinement is testament to my lack of skill, as my cuts are rough I cut 1mm outside of my score and place the sheet in a vice with a length of angle iron each side, then file down to the score. Pretty good finish. But I would prefer a machine to do this; my wood table saw (Proxxon FET) cuts very accurately, straight and smooth but imho only works with wood. If there were a table saw that did to non ferrous metals what the FET does to wood... I guess its machine up or skill up and as a retiree who has never dirtied his hands with engineering before, skilling up seems the greater challenge. Stuart |

| John Smith 47 | 27/04/2021 12:46:28 |

| 393 forum posts 12 photos | @Nicholas Farr - I wonder what would a 10x5 mm square look like in close-up? Further more when you zoom right in, there will be at least a little rounding.

@Stuart Munro - have you ever tried putting an abrasive cutting disk into your Proxxon FET?

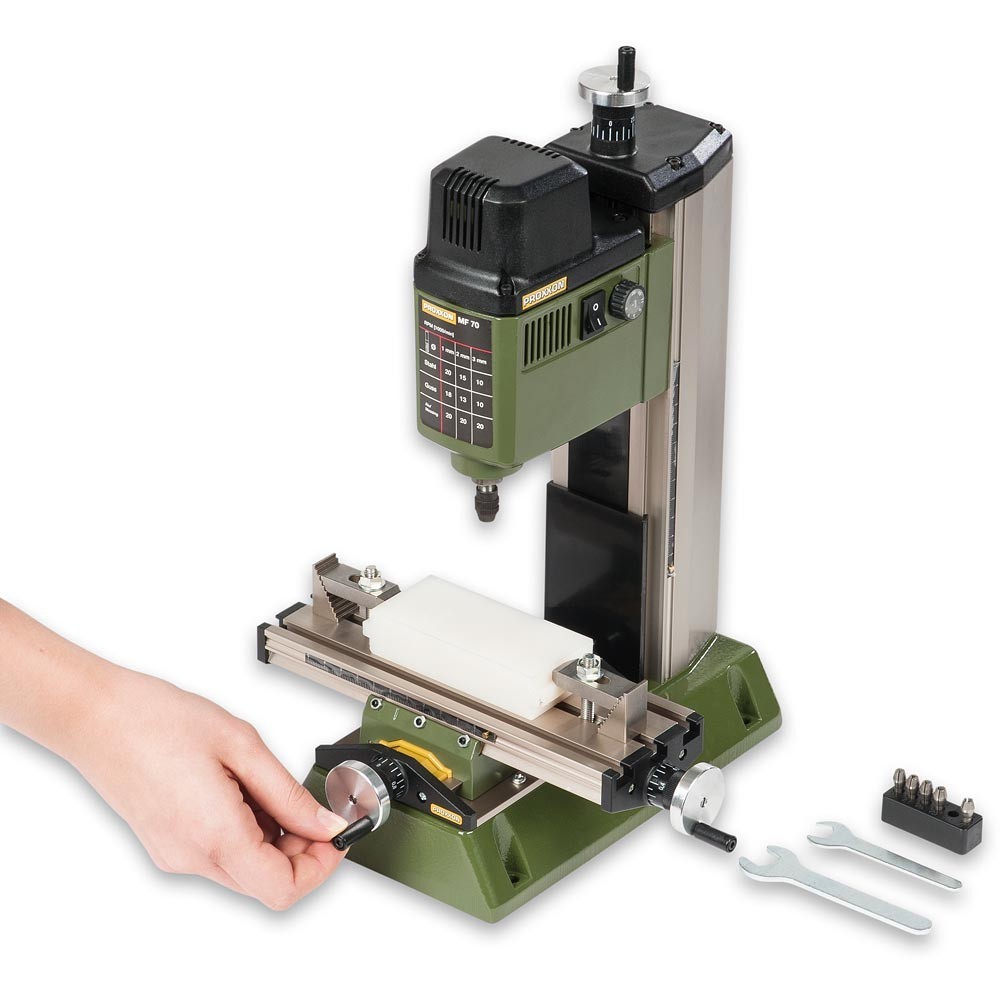

**LINK** It's rather under-powered at just 40w, and I'm sure faster would be better, but from experience 20,000 rpm can cut 0.1mm mild steel quite nicely without bending it near the cut. P.S. This will no doubt cause howls of abuse & derision but there is a high speed (20,000 rpm) low cost (c. £250) , compact, highly portable (7Kg) milling machine available... the MICRO Miller MF70, complete with its build quality and crappy run-out.

|

| John Smith 47 | 27/04/2021 12:57:05 |

| 393 forum posts 12 photos | PS |

| Michael Gilligan | 27/04/2021 13:16:25 |

23121 forum posts 1360 photos | That looks a nice little tool but [here we go again] ...

MichaelG. . They even offer GBP pricing: https://pepetools.com/products/4-guillotine-shear-made-in-usa Edited By Michael Gilligan on 27/04/2021 13:18:06 |

| Roger B | 27/04/2021 14:17:34 |

244 forum posts 105 photos | Stuart, Proxxon offer blades for the FET for non ferrous materials including the fine tooth 28730: |

| Nicholas Farr | 27/04/2021 19:24:01 |

3988 forum posts 1799 photos | Posted by John Smith 47 on 27/04/2021 12:46:28:

@Nicholas Farr - I wonder what would a 10x5 mm square look like in close-up? Hi, John, well these three pieces are approximately 10mm x 5mm, didn't get too fussy with the size, but I'm still not claiming they are absolutely flat and you might be able to make out the 0.015mm thick piece of kitchen foil in front front of them. Best I can do I'm afraid. They are sitting on the back of my 6" Moore & Wright straight edge. Regards Nick. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

![20210423_140044[1].jpg 20210423_140044[1].jpg](/sites/7/images/member_albums/44290/892901.jpg)

Register

Register Log-in

Log-in