Scale model Economy hit & miss engine builders wanted

I need to get my engine running

| Charles 2010 | 13/10/2010 20:12:47 |

84 forum posts 54 photos | Thanks for the info ...

Sound like do the holes first and then use that to mount onto round block and hold in a chuck or may be make up spacers to bolt to a face plate !!!

Thanks for the input Jason. |

| JasonB | 13/10/2010 20:15:26 |

25215 forum posts 3105 photos 1 articles | Sq block is easier than round as you can just turn it 90deg in the machine vice, round block would take a bit more effort to line up.

J |

| Charles 2010 | 13/10/2010 20:48:16 |

84 forum posts 54 photos | Good thinking !!!! |

| Andrew Johnston | 14/10/2010 12:11:55 |

7061 forum posts 719 photos | Charles, I remember mounting the cylinder head on a piece of aluminium angle, for use in the 4 jaw chuck on the lathe. This allowed machining of the spigot that fits in the cylinder. Once this is done, the head can then be mounted in the vertical mill, with the DRO zero'd at the centre. Then all the flat surfaces can be machined and the holes drilled. I'll have a go at trying to find the jig later today. If I do find it, I'll post a picture of it. Regards, Andrew |

| Charles 2010 | 14/10/2010 12:43:00 |

84 forum posts 54 photos | Thank you Andrew ..

That will be the way forward...

I hope you can find the photo ..

Regards Charles |

| Andrew Johnston | 14/10/2010 18:44:22 |

7061 forum posts 719 photos | Hi Charles, I've eventually found the jig, hiding behind the aluminium offcuts bin. Two photos have been added to my 'Economy' album. One is of the jig and the other shows how the cylinder head was mounted. The inlet and exhaust port faces were cleaned up and tapped M6 before mounting. As you have no doubt realised the thread callout of 1/2" BSP is wrong. I used M12 instead. Regards, Andrew |

| JasonB | 14/10/2010 20:02:13 |

25215 forum posts 3105 photos 1 articles | Any specific reason for going with M12 Andrew? I would have thought 1/4BSP a better option as the carb seems to be attached to the head with a standard street elbow looking at the pic on Engineers Emporium, can't quite see the exhaust but looks liek a nipple and malable iron elbow, again readily available in 1/4" BSP.

Jason |

| Andrew Johnston | 14/10/2010 22:51:37 |

7061 forum posts 719 photos | Hi Jason, I chose M12 as I already had all the necessary taps and dies and didn't, at the time, have any BSP threading equipment. I am not sticking exactly to the design in this area, so the availability of off-the-shelf elbows is of less concern to me than it might be to other makers. Regards, Andrew |

| John Wood1 | 15/10/2010 16:02:51 |

116 forum posts | Yes, 1/4 BSP is what LA Services use to fit standard iron elbows which is also what they use on theirs - and mine.

Charles, lots of gen on the way to you, see separate e-mail.

Luck to all

John |

| Charles 2010 | 16/10/2010 09:08:04 |

84 forum posts 54 photos | Thans John I look forward to seeing the other email soon.

It was nice to be ale to see a completed engine at the show yesterday and to take a lot of photos and also one being put together... |

| Charles 2010 | 16/10/2010 22:26:59 |

84 forum posts 54 photos | Is spring steel necessary for two parts in the Economy Engine or has any one used anything else. ??

If spring steel is needed where does one obtain it and secondly how does one cut it???

Regards Charles |

| Andrew Johnston | 17/10/2010 10:26:21 |

7061 forum posts 719 photos | I haven't made those bits yet, but it didn't occur to me to make them from anything but spring steel. I bought my spring steel from Folkestone Engineering Supplies. It comes annealed, so the issue is not how to cut it, but how to harden and temper. Not a problem for me as I have an electric heat treatment furnace. I don't suppose the hardening and tempering is that critical, so could be done by other means. Regards, Andrew |

| Charles 2010 | 18/10/2010 20:09:44 |

84 forum posts 54 photos | I too have a small kiln that will reach the 820C and then quench in oil and then heat to 350C and hold for 2 hours.

I asve been able to find the product on that company's web site so will get mine from there too.

I am now also thinking about the timber supports for the engine has anyone any ideas ?? |

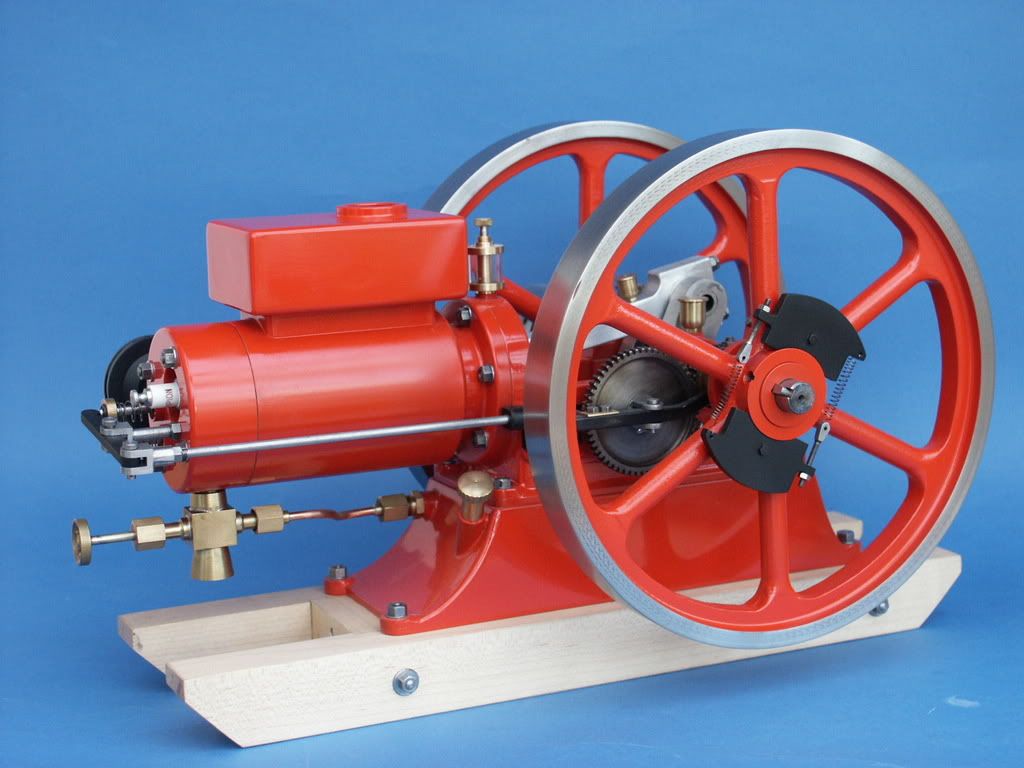

| JasonB | 18/10/2010 20:27:49 |

25215 forum posts 3105 photos 1 articles | I made my skids from maple, beech would also be suitable

Edited By JasonB on 18/10/2010 20:28:52 |

| Charles 2010 | 18/10/2010 20:43:45 |

84 forum posts 54 photos | I wonder what the dimensions of the timbers are I guess about 38mm x 60mm

I like the cross members to give strength

Nice see such a fine picture too.

Regards Charles Edited By Charles 2010 on 18/10/2010 20:44:42 |

| JasonB | 18/10/2010 20:54:26 |

25215 forum posts 3105 photos 1 articles | Much smaller than that, the model has 7" flywheels and the timber is 20x26 finish size, for your slightly bigger engine something like 25x30 would look OK.

Have a look at some of the sites with photos of full size engines and base your design on that, wheeled trolly would look good

The Florida Freewheelers photos here are a good place to start The Florida Freewheelers photos here are a good place to startJason |

| Charles 2010 | 18/10/2010 21:03:10 |

84 forum posts 54 photos | Thanks for the info Jason

I will look at various site and then decided but the 25x30 sound very good ...

Regards Charles |

| Andrew Johnston | 18/10/2010 21:44:57 |

7061 forum posts 719 photos | I'm planning to mount my engine on a piece of jig plate, along with a separate fuel tank and ignition system. There should be room on the plate to mount something for the engine to drive, if I felt so inclined. Regards, Andrew |

| Charles 2010 | 23/10/2010 00:02:51 |

84 forum posts 54 photos | Has anyone considered using a Helicoil in association with the spark plug to eliminate ware on the thread in the Aluminium casting?

The idea was given to me by my car repair mechanic who thinks that a spark plug in aluminium is just asking for trouble ...

|

| Ian S C | 23/10/2010 12:31:30 |

7468 forum posts 230 photos | A bronze Helicoil would be best to aid heat conduction, perhaps not important in this case, but someone here in NZ put a stainless helicoil in thr engine of his ultralight aircraft, the spark plug over heated and the engine failed causing an emergency landing to be made writing off the aircraft. Ian S C |

Please login to post a reply.

Magazine Locator

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our Newsletter

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

Latest Forum Posts

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

Shopping Partners

Latest "For Sale" Ads

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

Latest "Wanted" Ads

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Get In Touch!

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

All Forum Topics > I/C Engines > Scale model Economy hit & miss engine builders wanted

Register

Register Log-in

Log-in