Lathework for Beginners

Please use this thread to ask questions of make suggestions about the series in MEW

| Ron Laden | 22/07/2018 09:50:57 |

2320 forum posts 452 photos | Well I dont think Nylon 6 is the easiest material to work with, I am still experimenting but mixed results so far. Andrews advice of cut slow with high DOC and feeds is certainly true. Its no use taking fine cuts with a low feed rate, it does not work. Its also true that the swarf just wont break and you have an ever increasing ball of it which tends to wrap around and hide the job. Parting off is also fun, it cuts ok but as yet I cant stop the outer edge of the cut having a thin raised wafer of swarf still attached. I found the easiest and neatest way to remove it is to use a slow speed and the tip of a Stanley knife. All good fun.

Edited By Ron Laden on 22/07/2018 10:07:40 |

| Ian S C | 24/07/2018 11:17:38 |

7468 forum posts 230 photos | Had a Nylon job the other day, doing repairs on one of our machines, just needed to shorten a Nylon chain guide 3" diametre by 1/.4", the block was 3" long, put it in the 3 jaw chuck, and using a fairly general purpose tool(the one that happened to be in the lathe), lined up and took the 1/4" of in one cut at about 350 rpm. A clean cut, no tangles. Ian S C |

| Ron Laden | 19/09/2018 10:37:00 |

2320 forum posts 452 photos | The parting tool in my HSS set is 3.2mm with a straight cutting edge, is there any advantage in putting a slight angle to the cutting edge. Parting off some aluminium this morning and I was getting a bit of chatter, the tool is sharp with a good edge and wondered if a slight angle would help. Also using the correct speed or near as damn it for turning and facing a given size of material is that speed good for parting or should the speed be adjusted when parting..? Ron |

| Tim Stevens | 19/09/2018 16:53:40 |

1779 forum posts 1 photos | Hello Ron In my experience, adding an angle to the business end of a parting tool causes the tool to deviate sideways. This can result in a conical face on the workpiece, if the angle is minor and the blade is stiff, or, complete failure and damage to the tool as well as the job. Others may have different results - let's see ... Cheers, Tim |

| Neil Wyatt | 19/09/2018 21:54:20 |

19226 forum posts 749 photos 86 articles | I think the best simple modification to a HSS parting tool is LBSC's fish-tail shape. Round the corners and put a notch in the end. It will tend to produce swarf that folds in on itself and doesn't jam, and it does an excellent job of side to side finishing cuts for crankshaft journals and the like. Neil |

| Hopper | 20/09/2018 01:15:41 |

7881 forum posts 397 photos | Posted by Ron Laden on 19/09/2018 10:37:00:

Also using the correct speed or near as damn it for turning and facing a given size of material is that speed good for parting or should the speed be adjusted when parting..? Ron Go slower when parting. Maybe half the speed or so. If chatter persists, slow down some more. Generous spraying of WD40 onto the cutting edge as you go helps when parting aluminium. Ordinary machine oil works OK for steel, and proper cutting oil even better. |

| Ron Laden | 20/09/2018 09:16:51 |

2320 forum posts 452 photos | Thanks guys that is helpful, I was obviously parting with too high a speed, I didnt reduce the speed from the speed I had been turning with. The aluminium parts are 20mm diameter and the 3.2mm parting tool seemed heavy for that size, but it is the only parting tool I currently have. I have just ordered a 1.6mm HSS tool with holder which I hope is more suited to smaller jobs. Ron |

| Bazyle | 20/09/2018 09:53:31 |

6956 forum posts 229 photos | The other big problem with parting is being bold enough to keep feeding in so the tool keeps cutting rather than doing a bit then rubbing and losing its edge. Take a moment to work out what rate of turning the handle keeps the cut biting at a couple of thou minimum per rev but not too fast that it digs in. Don't be too proud to finish off with a hacksaw as the initial cut guides the blade. Also if the part has a hole down it the breakthrough is a danger area for snatching the tool. Tighter gibs helps here. Sometimes you have to use a 'wide' tool and accept that more metal ends in swarf. Last year I was parting off 1mm discs with a 1.5mm tool and could have cried but they were only 5/16 dia so I bit my lip and took the hit to my wallet. |

| Ron Laden | 20/09/2018 10:16:37 |

2320 forum posts 452 photos | Thanks Bazyle, I have found that the 3.2mm tool works well as a grooving tool. I tried it on a sample yesterday in prep for turning the buffers. I didnt take too heavy a cut but it worked fine in elongating the grooves at the different diameters of the buffer ram and ram body. |

| Bob Mc | 20/09/2018 13:14:40 |

| 231 forum posts 50 photos | I'm glad someone mentioned parting problems again, I have had many problems with this myself and although I can part with reasonable results I can't say I have had an easy time, in the end I purchased a new smaller width hss blade with holder from a well known supplier, this is a 1/16 inch blade which I thought would make the cuts easier. I was disappointed again, the problem in the end is the blade holder supplied,..I looked at the one I had previously as well and I assumed they would both have been made so that fitting it in a normal toolpost set squarely would give the correct clearance angles at the sides of the blade, to my amazement I found that the holders are not made with an angled side face but are just at 90 deg so that there is no clearance at one side of the blade and double the clearance at the other; this causes the tool to move over and dig in to one side. I made a new toolholder so that there would be clearance either side of the blade...the results were very satisfying.. has anyone come across this before...? or is this obvious to the more experienced.. I am only too willing to learn.. Bob. |

| JasonB | 20/09/2018 13:47:34 |

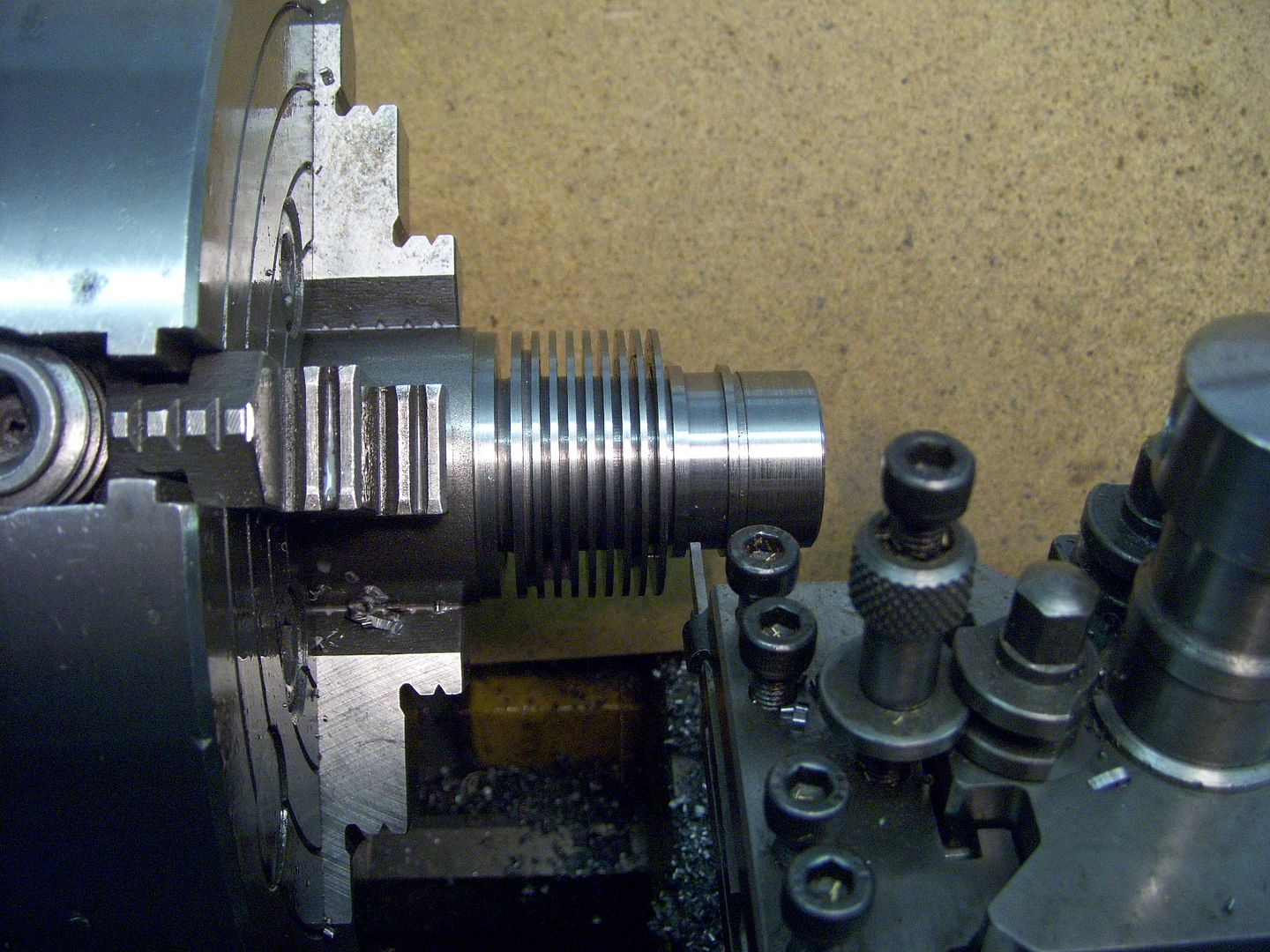

25215 forum posts 3105 photos 1 articles | I've not had problems with the 1.5mm type parting tools, this lot in 40mm dia steel went without a glitch, infact I made two such parts without even touching up the tool

|

| Ron Laden | 20/09/2018 14:04:41 |

2320 forum posts 452 photos | Well I,m hoping the 1.5mm tool and holder I have just ordered will be ok. Its a 8mm holder said to be suited to mini-lathes so fingers crossed.

|

| MW | 20/09/2018 14:06:38 |

2052 forum posts 56 photos | I have heard that ideally on a parting tool you want the sharpest corner/edge to be on the right side, so that the stock you're cutting off is going to have the clean face, rather than whats left behind. So that it kinda has a right skew. So that geometry kind of resembles a wood turners knife/parting tool. Michael W

Edited By Michael-w on 20/09/2018 14:11:44 |

| Andrew Johnston | 20/09/2018 20:16:07 |

7061 forum posts 719 photos | I use a straight 3mm insert blade on the manual lathe for parting off. I'm fairly cautious on speed, around 300-400rpm, but I do use power crossfeed and a minimum of 4 thou per rev, but usually 6 to 8 thou per rev. However on the repetition lathe I use a slanted HSS toolbit: I've never noticed it wandering, even when the parted off part has fallen away and I'm just removing the pip. For scale the collet is 1/4" so the blade is 1/8" x 5/16" and the overhang is about 3/4". I part off at the same speed I turn, about 1000rpm. Seems to work well, although the lathe is in the brick outhouse class. About the same footprint as a Myford ML7 but weighs three to four times as much. Andrew |

| JasonB | 20/09/2018 20:40:16 |

25215 forum posts 3105 photos 1 articles | I find the 1.5mm blades do wander if the end is ground at an angle particularly the mor eyou have sticking out so just grind mine straight. Wider and much deeper HSS blade that fits my toolpost holder is far more stiffer so can be angled if needed. |

| Bob Mc | 21/09/2018 21:24:29 |

| 231 forum posts 50 photos | Ha...! this is uncanny....! Re: my post 20.09.2018 in the latest issue (ME 4596) Graham Sadlers article series on "Lathes and more for beginners" actually says that some of the cheaper toolholders do not hold the blade properly giving no clearance either side and are best avoided.. As a famous person once or twice said... "I don't believe it ! " the makers of these bladeholders must surely know that they are making something destined to cause problems...for the sake of setting over the milling machine a degree or two when cutting the blade holder profile... it might work ...but its not right... and I noticed I got a better finish on the sides of the work when the blade was set correctly and is a delight to work with. Manufacturers in the Eastern countries making many of these tools very rarely puts its name on its products, I may be old fashioned but I do remember reading many years ago not to buy anything where the manufacturer was not confident in putting his name on what he has produced, I am minded to send it back to the supplier. Bob.

|

| Neil Wyatt | 21/09/2018 21:50:37 |

19226 forum posts 749 photos 86 articles | Posted by Bob Mc on 21/09/2018 21:24:29:

Ha...! this is uncanny....! Re: my post 20.09.2018 in the latest issue (ME 4596) Graham Sadlers article series on "Lathes and more for beginners" actually says that some of the cheaper toolholders do not hold the blade properly giving no clearance either side and are best avoided.. As a famous person once or twice said... "I don't believe it ! " the makers of these bladeholders must surely know that they are making something destined to cause problems...for the sake of setting over the milling machine a degree or two when cutting the blade holder profile... it might work ...but its not right... and I noticed I got a better finish on the sides of the work when the blade was set correctly and is a delight to work with. Manufacturers in the Eastern countries making many of these tools very rarely puts its name on its products, I may be old fashioned but I do remember reading many years ago not to buy anything where the manufacturer was not confident in putting his name on what he has produced, I am minded to send it back to the supplier. Bob.

Most of these toolholders are designed to work with parallel sided blades. Rather than Graham's tool being badly designed, I think it was supplied with the wrong blade, presumably the same supplier for yours too. I have two bought parting toolholders with vertical slots and one I made myself, all of which are used with parallel blades and work very well, thank you. It's a myth that parallel parting blades will jam - but they must be held vertically. Neil Edit: home made holder for parallel blade:

Edited By Neil Wyatt on 21/09/2018 21:53:50 Edited By Neil Wyatt on 21/09/2018 21:54:53 |

| Ron Laden | 23/09/2018 09:20:34 |

2320 forum posts 452 photos | Posted by Bob Mc on 20/09/2018 13:14:40:

I'm glad someone mentioned parting problems again, I have had many problems with this myself and although I can part with reasonable results I can't say I have had an easy time, in the end I purchased a new smaller width hss blade with holder from a well known supplier, this is a 1/16 inch blade which I thought would make the cuts easier. I was disappointed again, the problem in the end is the blade holder supplied,..I looked at the one I had previously as well and I assumed they would both have been made so that fitting it in a normal toolpost set squarely would give the correct clearance angles at the sides of the blade, to my amazement I found that the holders are not made with an angled side face but are just at 90 deg so that there is no clearance at one side of the blade and double the clearance at the other; this causes the tool to move over and dig in to one side. I made a new toolholder so that there would be clearance either side of the blade...the results were very satisfying.. has anyone come across this before...? or is this obvious to the more experienced.. I am only too willing to learn.. Bob. Bob, I received my 8mm parting tool holder and 1.6mm blades yesterday, like yours the blade face on the holder is square. There is not a problem though as the blades supplied with mine are parallel sided with no angles. The cutting end of the blade is ground as a reverse taper. Did some parting this morning and it cut and parted fine. Did you check with the supplier to see if they had supplied you the wrong blades for the holder..? Ron

|

| Bob Mc | 23/09/2018 11:37:37 |

| 231 forum posts 50 photos | Hi Ron, thanks for your message.. I have looked at the suppliers website but they don't actually give any information about the blade or holder other than give its overall dimensions, I suppose I should contact them and ask but I have now made a fitting for my toolpost which puts it in the right orientation and I don't hold much hope out for getting a meaningful response from the supplier as I contacted them previously about another purchase and received an unhelpful reply. I have to say that with the setup I have now, I am pleased with the way it produces a nice shiny face on both sides of the work rather than the previous flat face setup which produced rough faces and has no chatter with the metal coming off in nice curls...and it just sounds right, and I have ground the blade in the normal way with a flat edge and with the tool fitted to the topslide, no need for rear toolpost or any fancy grinding ....anyway thanks again for your reply to my post. ..Bob.. |

| JasonB | 23/09/2018 13:16:39 |

25215 forum posts 3105 photos 1 articles | If you do want to holed a tapered blade in a flat sided holder then a thin piece of fuse wire or a strand of flex against the bottom edge of the blade will have it standing upright so you get equal clearance both sides. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in