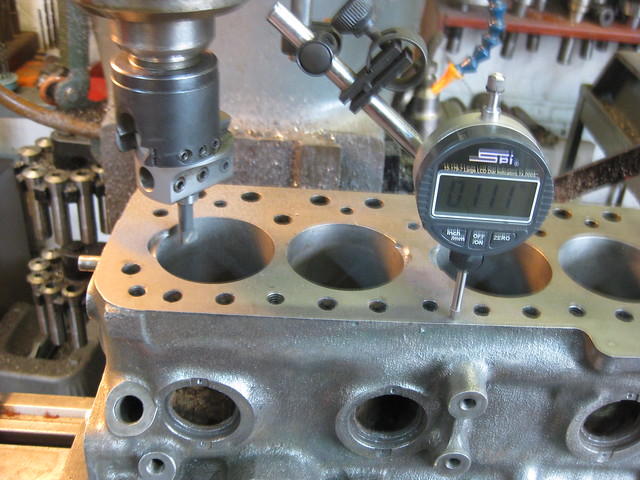

Opening a Port

Mill or Grind

| Phil P | 01/01/2020 12:32:00 |

| 851 forum posts 206 photos | I run an Accurite electronic ignition which is housed in the distributor but does away with the points and condenser. It has been extremely reliable so far, but I do carry a spare distributor just in case. !! It makes for a much smoother running engine with the added bonus of better fuel economy as well. Some purists would not entertain the idea of electronics on a classic car though. Why do you ask ? Phil |

| Howard Lewis | 01/01/2020 13:06:15 |

| 7227 forum posts 21 photos | The time and effort spent in matching ports, manifold and joint will be well repaid on any engine. A 1565cc Renault 16 given this treatment would match a 2 litre Vauxhall or Ford for acceleration or top speed! Don't overdo the hot spotting, to maximise charge density. BUT if overdone, you could suffer icing, which will bring things to a halt, until it thaws out. DON't ask! You need just enough heat input to match the latent heat of vapourisation of the petrol. Heating from the coolant will provide the most easily adjusted and controlled method, if possible. Sharp edges in the tracts, cause turbulence, and impede flow. Someone once said "Getting the gas into, or out of an engine determines whether it is a pig or a horse" So don't forget to ensure that the exhaust system does not cause too much back pressure, but remember that a little may be beneficial in preventing loss of charge on the overlap. If you want improved performance, you can tune the exhaust system, but remember that what works at one speed could work against you at another! Howard |

| not done it yet | 01/01/2020 13:41:26 |

| 7517 forum posts 20 photos |

A question on electronic ignitions: I have encountered Accuspark electronic systems but not Accurite. Please can you provide a link? I’m not overly enthusiastic about the reported reliability of the accuspark versions. I have made made a better electronic system in the past - but it either lacked starting energy or real high end power (due to inverter limitations at the time). Richard (Islip Minor on the morris minor forum) has a far better electronic system on his minor (which really goes like - -ink). |

| Phil P | 01/01/2020 14:05:09 |

| 851 forum posts 206 photos | NDIY You are correct, I was getting my Accu's muddled up with the DRO system I used to have. It is an Accuspark unit on the car. I too have heard about some folks having reliability issues with them, but so far mine has been excellent, like I said I do carry a spare just in case. Phil |

| vintage engineer | 01/01/2020 18:33:47 |

293 forum posts 1 photos | Yes that's the one, a typing error on my part. I ran a single 1 3/4" SU carb and 1 3/4" 3 branch stainless exhaust with this set up. Posted by Phil P on 01/01/2020 10:54:53:

Hi Vintage Engineer. I think you might be referring to the 12G295 head, I used to run one of those on my Mini van when I was a lad in the 70's. If I used one now I would need a bigger carb and exhaust to take advantage of it as well. To be honest I am not trying to make the Traveller go a lot faster, I am just taking the opportunity to build the engine to a better standard than they were when mass produced, I am static balancing all the moving parts and being careful with the cam timing, fitting duplex timing set up etc etc. I am after a smoother running reliable engine that I dont need to be spannering in years to come. Phil

|

| Stueeee | 02/01/2020 09:52:37 |

144 forum posts | I've used the 12G295 or the near identical 12G206 Cooper 998/MG1100 head in the past on 1000cc 'A' series motors, One of the issues (other than rarity) with these heads is the large amount that needs skimming off the head if you're not using flat top (or 'pop up' pistons) a .070" plus skim often results in a break in to the rocker feed oilway drilling that runs across the face of these heads. Nowadays I use the 12G940 head from the 1275cc motors, It has bigger valves, less volume in the combustion chamber, so needs less skimmed off to attain a decent compression, the rocker oil feed drilling doesn't run across the head face, and if it's a late (1987 onwards IIRC) head it will have factory fitted hard valve seats suitable for unleaded petrol.

When this head goes on a small bore (i.e. 850/950/998/1098cc) motor it needs to be fitted along with the 1275 rocker gear and head gasket as the valve spacing is different on the 1275cc head. The 1275 exhaust valve opens over the edge of the cylinder on the small bore motors, so if the head has been skimmed, or you are running a high lift cam, reliefs need to be cut into the block.

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in