Clarke Metal Lathe CL300M

Not working

| John Rudd | 25/06/2016 18:50:50 |

| 1479 forum posts 1 photos | Ok, Where abouts are you, maybe someone on here local to you can lend a hand? |

| zak moussa | 25/06/2016 19:49:19 |

| 17 forum posts | Posted by John Rudd on 25/06/2016 18:50:50:

Ok, Where abouts are you, maybe someone on here local to you can lend a hand? London |

| zak moussa | 25/06/2016 19:51:33 |

| 17 forum posts | Posted by SillyOldDuffer on 25/06/2016 18:49:34:

Hi Zak, Bad luck! I had a near miss with my similar mini-lathe when a length of swarf found its way along the lead-screw and into the electronics. There was a blue flash and smoke. I was lucky and the lathe still worked. I notice that your pictures seem to show a lot of swarf inside the control box. It looks as if there's a quite a pile on the right hand side under the lead-screw and other bits scattered around. If it is swarf, the first thing to do is to remove it. You should also remove the clear plastic bag that protects the circuit board and carefully remove any metal shreds that might have found their way inside. It's possible that there's swarf under the board as well. Then you can start debugging the electronics. I can't help with that because I upgraded from a mini-lathe and no longer have it or the manuals. I remember that the most common fault is blown FETS, but f necessary you can buy a replacement board. I stopped more swarf getting in by reducing the gap between the lead-crew and control box with some electrical tape. Cheers, Dave Theres no way bits of allu got inside its sealed tight looks like it could be a blown fett or the capacitor theres no bag is sheet of clear plastic |

| zak moussa | 25/06/2016 19:58:19 |

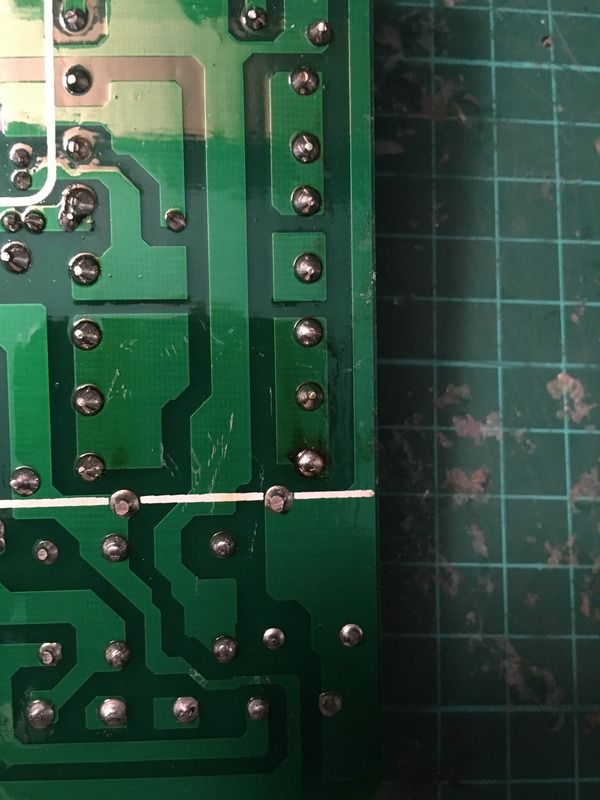

| 17 forum posts | This Resistor looks blown but the multimeter does give a reading Edited By zak moussa on 25/06/2016 20:00:06 Edited By zak moussa on 25/06/2016 20:00:39 Edited By zak moussa on 25/06/2016 20:00:46 |

| Bootlegger Blacky | 25/06/2016 20:47:31 |

54 forum posts 11 photos | Hi,best bet is search eBay for a generic motor control board,i found one from China £18. And had no problem since.just check the output against your motor size,,mine was 300watts.good luck!

|

| SillyOldDuffer | 25/06/2016 21:27:32 |

| 10668 forum posts 2415 photos | Posted by zak moussa on 25/06/2016 19:51:33:

Posted by SillyOldDuffer on 25/06/2016 18:49:34:

Hi Zak, Bad luck! I had a near miss with my similar mini-lathe when a length of swarf found its way along the lead-screw and into the electronics. There was a blue flash and smoke. I was lucky and the lathe still worked. I notice that your pictures seem to show a lot of swarf inside the control box. It looks as if there's a quite a pile on the right hand side under the lead-screw and other bits scattered around. If it is swarf, the first thing to do is to remove it. You should also remove the clear plastic bag that protects the circuit board and carefully remove any metal shreds that might have found their way inside. It's possible that there's swarf under the board as well. Then you can start debugging the electronics. I can't help with that because I upgraded from a mini-lathe and no longer have it or the manuals. I remember that the most common fault is blown FETS, but f necessary you can buy a replacement board. I stopped more swarf getting in by reducing the gap between the lead-crew and control box with some electrical tape. Cheers, Dave Theres no way bits of allu got inside its sealed tight looks like it could be a blown fett or the capacitor theres no bag is sheet of clear plastic Hi Zak, Sorry about that - I completely misread the photo. Now I'm feeling foolish, especially as I then proceeded to type "plastic bag" when I meant plastic sheet. Doh! Cheers, Dave |

| Howard Lewis | 25/06/2016 22:09:17 |

| 7227 forum posts 21 photos | If you need spares, talk to Ketan at Arc EuroTrade. He is a most helpful chap! I'm guessing that your lathe is actually a Seig C2, with a 300 Watt motor,and although ARC don't sell them, they do sell spares. Including fuses, and a "rubber" dirt excluder to fit around the Leadscrew where it passes into the Control Box. You may even be able to get hold of a user manual for it. The one thing that, I gather will destroy the circuit board, is to start up with the speed control set above minimum. I think it was Ketan who posted on another thread about the C2, a list of ways of messing up the electronics. DO find the other thread and read through it; it includes a hand drawn circuit diagram, and LOTS of info and advice. The manual for my C3 (which has a different, and non interchangeable, 350W motor and control board) definitely says "CAUTION: Always turn the speed control to the minimum speed position before starting the lathe. Starting the lathe with the speed control control set to a higher speed can damage the speed control circuit board" It also advises a maximum cut of 0.010 inch (0,25mm) when roughing. Remember it is only a small lathe with a 300 W motor, so big cuts are a No No. Also, heavy loads at low speed can cause the motor to overheat, also at low sped you have a lot less torque available. There are a lot C2s and C3s around, and people have done a lot of good work on them, and made a number of accessories and mods to improve their versatility. (Heeding a warning from Mike Cox, about swarf finding its way through the mandrel and falling inside amongst the plastic change gears, I have just made a simple extension for the mandrel to ensure that any swarf falls out of the back, rather than inside). Hope that this is some help. Howard

|

| Howard Lewis | 25/06/2016 22:21:57 |

| 7227 forum posts 21 photos | Put "Mini Lathe" or "CL300" in the search box for "All Topics". This has a number of threads about the Seig C2, all of which you will find informative. The thread that i was thinking of has about 180 posts, and is headed "Mini lathe speed control board pcb" Howard |

| John Rudd | 26/06/2016 08:57:23 |

| 1479 forum posts 1 photos | Posted by Howard Lewis on 25/06/2016 22:09:17:

The one thing that, I gather will destroy the circuit board, is to start up with the speed control set above minimum. Howard

I thought the speed pot was interlocked in such a way that if the power to the lathe was interrupted/ the direction of the motor was changed/the motor stopped because of the fault light coming on that the speed pot has to be returned to the off position to reset the interlock? I stand to be corrected of course... |

| Anthony Knights | 26/06/2016 09:16:04 |

| 681 forum posts 260 photos | John You are correct (thats how mine works anyway) |

| Neil Wyatt | 26/06/2016 10:18:06 |

19226 forum posts 749 photos 86 articles | Posted by Anthony Knights on 26/06/2016 09:16:04:

John You are correct (thats how mine works anyway) And how mine worked - until a long curl of swarf found its way into the control box... Don't believe the 0.010"' for roughing cuts! Even a 300W C2 is capable of far more than that. Neil |

| SillyOldDuffer | 26/06/2016 10:23:24 |

| 10668 forum posts 2415 photos | Posted by John Rudd on 26/06/2016 08:57:23:

Posted by Howard Lewis on 25/06/2016 22:09:17:

The one thing that, I gather will destroy the circuit board, is to start up with the speed control set above minimum. Howard

I thought the speed pot was interlocked in such a way that if the power to the lathe was interrupted/ the direction of the motor was changed/the motor stopped because of the fault light coming on that the speed pot has to be returned to the off position to reset the interlock? I stand to be corrected of course... Depends on the model I think. My mini-lathe didn't have a pot at all. It used touch buttons to adjust the speed and it was impossible to start up the lathe at maximum speed. The board was physically very different from Zak's too. Dave |

| An Other | 26/06/2016 10:40:43 |

| 327 forum posts 1 photos | Hi, Zak - I'M with John Swift on this one. You say the motor seems to be OK, so it is almost certainly the two FETs bolted to the big heatsink that have failed - it happened to me about 6 or 7 times. There are newer control boards available which seem to be able to withstand overloads much better than this older type. You can proabaly get the newer one from ARC. The FETs are cheap enough and it only takes a few moment to unsolder and unbolt them to fit new ones - they are not too difficult or expensive to buy (try Maplins). It is worth a try before paying ~100 pounds for a new board. If you have access to an Ohmmeter, there is usually a short circuit between two or more pins of the FETs - usually dead short, only a few ohms.

|

| zak moussa | 26/06/2016 10:52:32 |

| 17 forum posts | Posted by An Other on 26/06/2016 10:40:43:

Hi, Zak - I'M with John Swift on this one. You say the motor seems to be OK, so it is almost certainly the two FETs bolted to the big heatsink that have failed - it happened to me about 6 or 7 times. There are newer control boards available which seem to be able to withstand overloads much better than this older type. You can proabaly get the newer one from ARC. The FETs are cheap enough and it only takes a few moment to unsolder and unbolt them to fit new ones - they are not too difficult or expensive to buy (try Maplins). It is worth a try before paying ~100 pounds for a new board. If you have access to an Ohmmeter, there is usually a short circuit between two or more pins of the FETs - usually dead short, only a few ohms. I have a meter and your right the first and middle pin is short on the second fett, compared to the first i am assuming they are the same rating I will go to RS and buy two fets swap them over and see if that makes a difference

|

| zak moussa | 26/06/2016 10:53:24 |

| 17 forum posts | Posted by Howard Lewis on 25/06/2016 22:21:57:

Put "Mini Lathe" or "CL300" in the search box for "All Topics". This has a number of threads about the Seig C2, all of which you will find informative. The thread that i was thinking of has about 180 posts, and is headed "Mini lathe speed control board pcb" Howard I found it so much information looks like its either the fett or the cap 22 |

| zak moussa | 26/06/2016 10:55:36 |

| 17 forum posts | Posted by Howard Lewis on 25/06/2016 22:09:17:

If you need spares, talk to Ketan at Arc EuroTrade. He is a most helpful chap! I'm guessing that your lathe is actually a Seig C2, with a 300 Watt motor,and although ARC don't sell them, they do sell spares. Including fuses, and a "rubber" dirt excluder to fit around the Leadscrew where it passes into the Control Box. You may even be able to get hold of a user manual for it. The one thing that, I gather will destroy the circuit board, is to start up with the speed control set above minimum. I think it was Ketan who posted on another thread about the C2, a list of ways of messing up the electronics. DO find the other thread and read through it; it includes a hand drawn circuit diagram, and LOTS of info and advice. The manual for my C3 (which has a different, and non interchangeable, 350W motor and control board) definitely says "CAUTION: Always turn the speed control to the minimum speed position before starting the lathe. Starting the lathe with the speed control control set to a higher speed can damage the speed control circuit board" It also advises a maximum cut of 0.010 inch (0,25mm) when roughing. Remember it is only a small lathe with a 300 W motor, so big cuts are a No No. Also, heavy loads at low speed can cause the motor to overheat, also at low sped you have a lot less torque available. There are a lot C2s and C3s around, and people have done a lot of good work on them, and made a number of accessories and mods to improve their versatility. (Heeding a warning from Mike Cox, about swarf finding its way through the mandrel and falling inside amongst the plastic change gears, I have just made a simple extension for the mandrel to ensure that any swarf falls out of the back, rather than inside). Hope that this is some help. Howard Thanks for the info looks like i was taking way too much off at each time : i found the board on the website you suggested close to £100 yikes http://www.arceurotrade.co.uk/Catalogue/Machine-Spares/C2-Mini-Lathe-Spares/C2-182A-Control-Board-FC250J |

| zak moussa | 26/06/2016 10:56:02 |

| 17 forum posts | Posted by Bootlegger Blacky on 25/06/2016 20:47:31:

Hi,best bet is search eBay for a generic motor control board,i found one from China £18. And had no problem since.just check the output against your motor size,,mine was 300watts.good luck!

Any links to one so many to choose from cant find the exact one |

| John Rudd | 26/06/2016 17:38:46 |

| 1479 forum posts 1 photos | Choose a controller carefully.... They are not all the same....you need one that is suitable for a dc motor.... The mosfets are IRFP460 from memory, you buy them from ebay cheap enough if you can wait a few days or pay RS prices...the printed circuit board although uses thru hole technology, when it comes to removing components be careful. I suggest you unbolt the mosfets and cut the leads close to the body, then use thin nose pliers and a decent iron to remove the legs. The printed tracks are easily damaged- first hand experience, I've repared a number of these and other Chinese boards..,,, Edited By John Rudd on 26/06/2016 17:39:31 |

| Ketan Swali | 26/06/2016 20:55:36 |

| 1481 forum posts 149 photos | Hi Zak, In some ways your post reminds me of another Londoners post on here, who has the same problem as you. Make yourself a big flask of your favourite brew and go through this link When you purchased off Gumtree, was it working fine, had it been used regularly?, do you know if there were sparks flying from the motor, or had the machine not been used for a while, parked in a cold and damp shed? When things went 'poof' as you say, what exactly resulted in it going 'poof'? Had you correctly engaged into the hi gear? Had you checked that the machine worked correctly in both settings when you bought it from the seller? did you dig in into the material you are trying to turn? This circuit board has no overload protection. To the best of my knowledge, non of the brushed C2 = CL300M mini-lathe do. Same applies to ALL of the cheapest option brushed model control boards in the market place. Simple way of checking is usually there is no fault light on such machines - I think. This means that overload can blow the board, being it from abuse/abnormal use due to lack of training, or dirty power. What is the quality of power in your area? what is the quality of wiring in your premises?. For anyone who has a C2, we always recommend use of a cheap surge protector plug fitted directly to the wall socket to which the machine is connected. Replacement control boards are supplied without guarantee or warranty as they are tested before dispatch. 25% of buyers still blow them because they fail to carry out the correct tests on the motor, or proceed to abuse/carry on regardless etc...Then we get into any argument!....hence one of the reasons for the price being what it is. You can read into that as you wish Did you ever buy a £20.00 car battery to carry out the test on your motor?..your picture suggests that you use a 'small battery' to test the motor. How fast or slow did the motor turn when it was connected to this battery? All you say is that the motor turned, which means nothing by itself. You suggest that you are ok with electronics in your opening post. Are you competent enough to use a multimeter, soldering iron, solder (original leaded may be), and do you have access to it?.. Your machine is old. The FC250J board came out before the XMT...before lead free solder. Old stocks of such boards are still kept and sold as spares. If you proceed to replace MOSFETs, do consider using higher rated MOSFETs. This was discussed in the early days, i.e. long time ago, but I can't remember which MOSFETs as ARC moved away from repair/upgrade a long while back after leadfree came into play. I can't guide you on this as I am not competent to advise details. All I can remember is that it had something to do with compensating for over voltage supply from dirty power. The current MOSFETs are correct, but they 'might not' deal well with unregulated supply, and you might end up in the same place given all the factors mentioned above. So, when one considers to blame such boards, do also consider to take into account ones own abilities to use a lathe, and un-regulated power. If you consider a generic control board, only do so if you really know exactly what you are doing. Otherwise, save yourself some time, read the long link thread mentioned above, in which all the good, bad and ugly ideas were discussed over time, and note that there seem to be continued issues relating to that project. I say this with the greatest of respect to all concerned. By the way, please don't think about asking ARC for different boards or motors as an upgrade to yours, as unfortunately this is not something we can offer. We only carry like for like replacements and we are unable to give guidance or advice on alternative replacement projects. Good luck with your journey. Ketan at ARC.

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in