Jasons tips

| Raymond Anderson | 07/04/2016 10:47:28 |

785 forum posts 152 photos | Hi Andrew, The CCGT inserts I prefer are the coated ones [ I will post a pic or 2 later on today ] some have a TiCN coating and the others are a combination of TiCN and TiAIN and I can report no problems with BUE on Aluminium . I have noticed it slightly on the un- coated types,but it hasn't [as of yet ] given me any problems. Although a lot would also depend on the type of Aluminium alloy. [amongst other things ] Cheers. |

| Emgee | 07/04/2016 10:58:36 |

| 2610 forum posts 312 photos | As stated earlier H13A is the recommended grade for non ferrous materials, H10 has a finer grain structure and is also recommended for non ferrous and plastic materials,not all ground inserts have a polished surface, chip breaking will also be dependent on the grade of aluminium being cut, some are stringy whatever grade of insert or tip shape is used. Agree BUE can be a problem if no lubricant used. Emgee Edited By Emgee on 07/04/2016 11:28:28 |

| Nick_G | 07/04/2016 12:53:24 |

1808 forum posts 744 photos | Posted by Andrew Johnston on 07/04/2016 10:32:20:

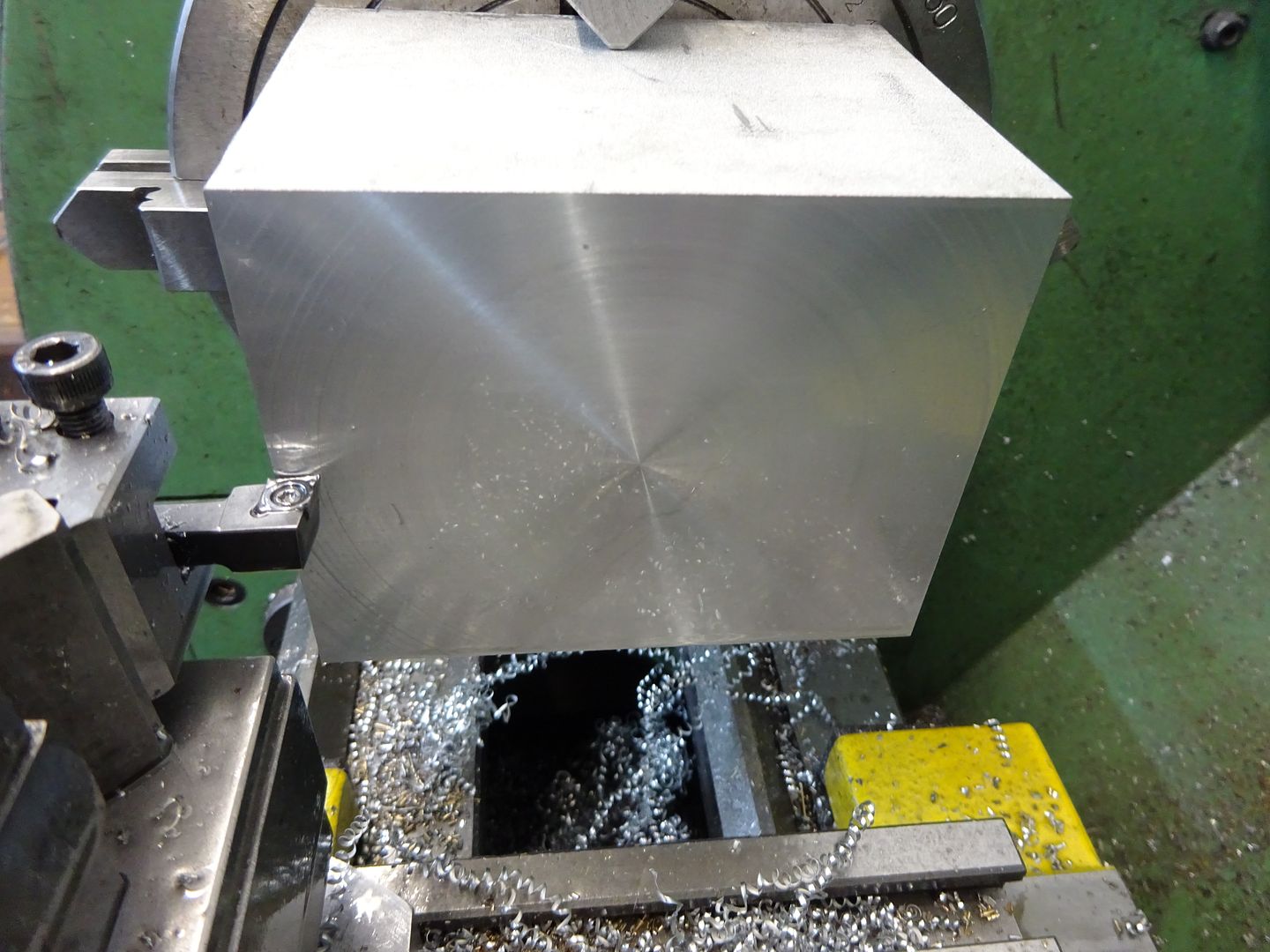

My expectation is that they will work fine on brass, but less so on aluminium, the two possible issues being BUE and chip breaking. Andrew . Here we go. I imagine you more knowing guy's will find the swarf shape tells the story.

|

| JasonB | 07/04/2016 13:09:24 |

25215 forum posts 3105 photos 1 articles | Looks very similar swarf to what I get with similar shallow cuts in 6082. The video actually shows the positive rake better than the photos as you can see that the corners of the tips rise up The brighter tips that I use

|

| Nick_G | 07/04/2016 13:16:22 |

1808 forum posts 744 photos | Posted by JasonB on 07/04/2016 13:09:24:

. Hey.!!! .......... You have the same chuck as me. How the hell did that happen.?

Nick |

| Muzzer | 07/04/2016 13:36:06 |

2904 forum posts 448 photos | It's all a bit confusing, despite supposedly being standardised (ISO-1832 etc?). Naturally there is room for ambiguity and Sandvik (page I-14) and Korloy seem to take a different approach within the same general guidelines. The first 2 (CC**) letters simply denote the shape and relief angle (80 degree rhombic and 7 degrees respectively). The 3rd character simply denotes a tolerance, not a sharpness or surface roughness parameter. The 4th letter denotes the "shape" of the insert, beyond those already defined, usually in section. The letter "X" seems to denote a "special" profile and that's what Sandvik chose to use to define their CCGT inserts to their own preference. Korloy on the other hand use the 4th letter to merely define the screw fixing and screw chamfer angle. The chipbreaker definition defines the top rake angle more than any other bit of the part number. So Korloy use the "-AK" and "-AR" chipbreaker suffices to define their high rake (and usually polished) geometry. I suspect the -AK is what Andrew showed (the shiny one). Bottom line, the Sandvik inserts seem to be CCGT indeed but these are not the aluminium / non-ferrous cutting flavour I suspect most of us thought were inferred by the CCGT part number. It's probably a fairly standard steel cutting insert although I don't see the "-UM" suffix anywhere. Perhaps I missed it? For Sandvik, it appears you would need to order a CCGX060203 part and for Korloy you'd want a CCGT060203-AK or -AR. Murray Edited By Muzzer on 07/04/2016 13:40:53 |

| Emgee | 07/04/2016 14:22:19 |

| 2610 forum posts 312 photos | Muzzer H13 denotes recommended for non-ferrous as does H13A, H10 and H10A. Sandvik use this code for turning and milling inserts suitable for non-ferrous which also includes titanium. The last 2 numbers in the code denote tip radius, as far as I can see thats in 02, 04, 08 rads, where did you get the 03 code ? Emgee Edited By Emgee on 07/04/2016 14:23:14 Edited By Emgee on 07/04/2016 14:25:01 |

| Raymond Anderson | 07/04/2016 17:59:49 |

785 forum posts 152 photos | |

| Raymond Anderson | 07/04/2016 18:02:52 |

785 forum posts 152 photos | Here are some pics I think a lot of folks thing that the **GT inserts are all shiny silver. These are some CCGT a WCGT and a CCGX note the various coatings. |

| Muzzer | 07/04/2016 18:19:13 |

2904 forum posts 448 photos | Posted by Emgee on 07/04/2016 14:22:19:

\where did you get the 03 code ? Emgee Haha. Finger trouble / senior moment - well caught. |

| James B | 08/04/2016 08:56:37 |

101 forum posts 14 photos | On the subject of insert size, where equipment allows, is there an advantage to using the 09 size over the 06 size? I have small and larger tool holders for 2 different lathes, but all use the smaller 06 size tips so I can share the tips. Would there be any advantage in buying alternative 09 size holders as well? Thanks, James

|

| Chris Evans 6 | 12/01/2017 21:00:16 |

2156 forum posts | An old thread I know but one I remembered and decided to try some "GT" tips. Ordered a cheap circa £10 box from China, arrived today and I tried them on 304 stainless. Brilliant finish, I am well pleased. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in