Huanyang VFD

Is it causing motor vibration?

| Bernard Wright | 25/05/2016 08:22:56 |

90 forum posts 16 photos | I've had this 4Kw(5.5Hp) VFD with pendant for quite a while now, and been extremely pleased with it.. Having lived with a bit of hunting noise from motor/clutch area, believing it to be poor belt/pulley & length of belt combination origin. However, of late I've been investigating several anomalies that have arisen since fitting a DRO to my Colly Master. (I posted a query regarding Spindle Bearing Adjustment) So started checking motor for vibration, removed belts(2), found some..., removed pulley (TaperLok), ran with key still seated..., vibration, removed key..., vibration, noted VFD frequency readings, vibration seemed to be from 22Hz-39Hz, ran smoothish at other freqs including full speed 60Hz. The motor is a Siemens 3ph 2 pole 2800rpm 2.2Kw/3Hp 220v/440v. My question to the forum, is it the motor or the VFD settings. As can be seen, I'm using a motor below the rated power of the VFD, would this need to be addressed? Are there settings to accomplish this, I've tried the Frequency Carrier setting PD041, it came set at 3, tried 5,7,8 & 10, nothing changed the hunting noise, so returned to 3. (at the time didn't realise the motor was vibrating, thought it was the length of the belts(they are long A78)) I'm contemplating buying another motor(new this time), but the Siemens looked very new...,I bought 2 motors at the time 2nd hand, fitted the other to my Elliott miller, NO probs at all that I've noticed, I presume because the miller is very sturdy and a bit noisy itself, both motors run from the same VFD,..NOT at the same time, they are switched(photo) Hope someone can help, it's driving me nuttts. Bernard.

|

| David Jupp | 25/05/2016 08:37:31 |

| 978 forum posts 26 photos | General comments - I've not used that particular brand of VFD. There is usually some option to set the motor power - used when running a motor smaller than the converter nominal rating. The exact details of how this is done vary - it will involve setting parameters. You may be able to set up different sets of motor parameters and switch between them using a digital input (maybe a spare contact on your lathe/mill selector switch). There can sometimes be vibration issues at specific frequencies - it is often possible to program VFD to 'skip' over a range of frequencies if this is the case. That isn't ideal if you want continuous range of speed available. If the VFD can be set to 'Vector' mode, that should give better speed control on a load like a machine tool compared to V-F mode for example. |

| Chris Evans 6 | 25/05/2016 09:04:25 |

2156 forum posts | I have the same make but slightly smaller output VFD running my 2 HP Bridgeport mill. No problems in nearly three years but I did have to get a friend who runs 5 of this brand VFD on his various machines to set it up. I can not understand the "Chinglish" in the instructions. |

| daveb | 25/05/2016 09:37:39 |

| 631 forum posts 14 photos | Is the VFD set for the motor nominal speed / number of poles? |

| Bernard Wright | 25/05/2016 09:58:33 |

90 forum posts 16 photos | Thanks for the input Gents. David J, I don't really want to skip speeds, what are these Vector settings about, as opposed to V-F, I've not come across these? daveb, not sure, actually don't know, what would this do, and where would I find it, do I have input somewhere 2840 rpm and 2 poles, sorry but I'm not too electronic savvy, I struggle to interpret manual jargon, but can readily follow some guidelines.. I seem to get the rated speed plus some, not sure how much though, for the extra 10Hz (0-60Hz) UK STD is 50Hz innit. Just read some other writeup, that there are Inverter friendly Motors available, what's that all about? Bernard Edited By Bernard Wright on 25/05/2016 10:15:40 Edited By Bernard Wright on 25/05/2016 10:18:33 |

| David Jupp | 25/05/2016 10:24:01 |

| 978 forum posts 26 photos | There is usually a group of parameters that relate to the motor (power, number of poles etc.). Some may be used just to make display of speed correct, some may actually affect behaviour of the inverter/motor or any external speed signal. You may get away with just setting a couple of parameters, and the inverter will 'optimise' the rest after measuring the motor electrical characteristics itself - you'd have to check the manual to see what is supported. If your two motors are a long way from being similar, you may always have issues unless the inverter does support multiple motor parameter sets. Inverter friendly, or inverter duty motors may well have higher rated insulation to cope with various side effects of using a VFD. Some inverter friendly motors may offer a separately powered cooling fan (the standard fan doesn't do much cooling when motor is running at low speed). |

| Bernard Wright | 25/05/2016 10:37:32 |

90 forum posts 16 photos | Hi David, Thanks for explaining that. Both motors are rated the same just different manufacturer, in fact I have three of the same, the other on my pillar drill, that is controlled by a separate pendant, due to having to pull out one of the switched plugs to plug in the drill. It seems, the seemingly flimsy mounted motors (i.e. Pillar drill & Lathe are on pivoted adjustable mounting plates) have the problem of vibration, the Miller isn't so noticeable, I presume due to the more solid mounting. I'm considering moving the motor on the lathe, to the back of the bed beneath the headstock, to solidify the mounting and shorten the belt run. Bernard. |

| David Jupp | 25/05/2016 11:05:23 |

| 978 forum posts 26 photos | It's still worth making sure the VFD parameters match the motor rating plate (if for nothing beyond making sure the motor protection function of the inverter is set correctly). Without knowing model of inverter, it's difficult to find a manual on-line and point you to the parameters. I presume you already know to always make sure a motor is connected before running the VFD, and not to switch motors when VFD is active. [EDIT - Sensorless Vector Control is a more advanced method of controlling the VFD, it'll hold speed better and cope with varying loads. V-F follows a fixed voltage profile (either linear or quadratic, depending upon type of load the motor is driving). Terminology may vary between manufacturers. ] Edited By David Jupp on 25/05/2016 11:11:10 |

| daveb | 25/05/2016 11:53:48 |

| 631 forum posts 14 photos | It sounds as if the inverter parameters need tweaking, the manual is such that Bernard really needs advice from someone with experience of this make of inverter. When properly set up, the motor should run without any vibration. |

| Bernard Wright | 25/05/2016 11:58:56 |

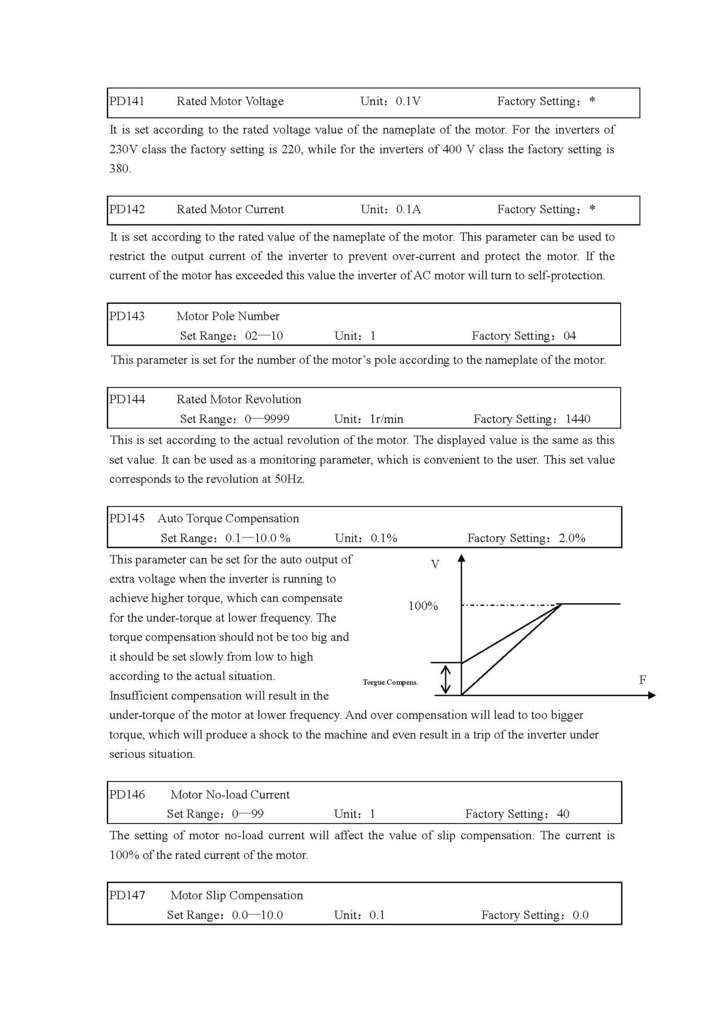

90 forum posts 16 photos | David, I wouldn't change any switches over without everything being off, but thanks anyway. This is helping no-end, I've downloaded a Huanyang Manual, I found the page relating to motor poles and rotational speed, these were PD143 & PD144, also found that the >> button shifts numerals quicker than just hold the ^ button. I changed these settings from 4 poles to 2 and 1440 rpm to 2880, tried the motor, no difference...bugger.(photo)

I'm next going to change the PD141 Voltage and PD142 Amperage setting for these motors, after inspecting the makers plate. Not sure what else I can change to get a vibration free setup... I appreciate your help. Bernard Edited By Bernard Wright on 25/05/2016 12:00:46 |

| David Jupp | 25/05/2016 12:58:24 |

| 978 forum posts 26 photos | Since motor looked fairly new, I assume the bearings are in good condition ? Could I suppose be some rotor imbalance. |

| Steve Pavey | 25/05/2016 13:30:36 |

| 369 forum posts 41 photos | I have a Huanyang vfd on my Harrison but haven't noticed any vibration. Before blaming either the vfd or the motor I'd be tempted to look at a mechanical reason - it sounds as though it is a sort of resonance issue. You've already hinted at this with comments about the drive belts and the motor mount. Maybe beefing up the motor mount would be the answer, or at least changing its' mass significantly. For a test try bolting or clamping a big lump of steel to it (a spare chuck for instance) - that might change the resonant frequency so it's out of your working range of speeds. I have always had a similar problem with my Startrite bandsaw - it only happens at very low speeds just before it slows to a stop, when the whole machine shakes and shudders for a brief moment. |

| john fletcher 1 | 25/05/2016 14:00:15 |

| 893 forum posts | There is on 'Youtube' a short video on setting up a Huanyang inverter viewing that might be of help.John

|

| Bernard Wright | 25/05/2016 14:08:52 |

90 forum posts 16 photos | I checked PD141, Voltage 220v, PD142, Amperage was 17.0A so altered that to 8.0A, tried the Pillar drill but it didn't seem any different, might just be me not remembering how it was before. There is about a thou runout on the very end of the 24mm dia motor shaft, I don't know if others are familiar with the Colly Roundhead Master motor to clutch pulley layout, but the motor is in the base cabinet to the rear, it's a good 2ft centres, hence the A78 belts. I've pondered putting an idler roller off a car serpentine belt layout, to reduce the whip, but think maybe a more solid mounting would be better, will have to measure up, I might have to alter the rear splash guard to accommodate the length of the motor, but that's not beyond me. The motor looked in pristine condition, I took it on faith the bearings were OK, didn't run any checks at the time, just wanted to get it bolted on, I'm wondering if the prolonged adverse VFD parameters have done the business to the motor's balance. The cabinet did have a bit of resonance before changing from a single phase to three phase, I tried to minimise that by rubber mounting the motor mounting plate, the captive type rubber mounts found on torque control arms on cars, loaded radially, didn't really work though. I'm nearly convinced the motor rotor is well out of balance, so think a new motor is the way to go, now settings are sorted. While typing this, John F posted about YouTube, I tried watching it but the filming was worse than mine, but thanks anyway. Bernard. |

| David Jupp | 25/05/2016 14:24:55 |

| 978 forum posts 26 photos | I wouldn't expect the incorrect parameters to have caused the rotor to become unbalanced. The current setting is largely a protection thing. Dose the motor run smoothly if removed from the machine and sat on the floor? |

| Steve Pavey | 25/05/2016 19:09:09 |

| 369 forum posts 41 photos | I can't imagine the motors rotor is out of balance, unless it's been physically damaged in some way. That wouldn't happen electrically. Even cheap import motors run smoothly in my experience. It is possible the bearings need replacing but you'd probably hear rather than feel the symptoms of that problem. However, bearings are fairly cheap so it might be worth changing them if you want to eliminate that possibility. If you want to check the settings on the vfd, there is a post by Mark C with some suggested parameters which I found very useful (near the bottom of page 3 of this thread **LINK** David Jupps suggestion of running the motor on the bench should be your next step, via the vfd so you can check it at 22-39 Hz. One other thought re the rubber bushings you tried out - if the motor was at fault the vibration should have been damped before it got transmitted to the rest of the machine. The fact that they didn't do much indicates that it is the machine vibrating rather than the motor. To me anyway! |

| Bernard Wright | 25/05/2016 19:40:32 |

90 forum posts 16 photos | Thanks to all you guys for the support and suggestions, I've learnt more about this damned VFD in this short time than I've done since getting one. I will remove the motor tomorrow, to test on the bench as I feel sure I did when wiring it up. The rubber bushes are very stiff, and may not be helping in the frequency range I'm using, just don't know I'm afraid. Bernard. Edited By Bernard Wright on 25/05/2016 20:20:24 |

| Bernard Wright | 26/05/2016 18:07:23 |

90 forum posts 16 photos | Took the motor off the lathe today, sat it on the bench, and connected up the VFD leads. I tried it without key or pulley, to eliminate any external influences, found varying degrees of vibration at various frequency(speed) settings. I then tyewrapped the key back in the seat, again same as above. So looked again at settings in the VFD, tried PD041 (Frequency Carrier). I'd already played with this months ago, due to reading on some forum(not sure which though), that noise emanating from the motor can be reduced by altering PD041. I thought I'd left is as default (3) after playing, but it was on (7), so altered that back to (3) and tried that...slight improvement (hooray), I then tried settings from (1 through 10), (3) and (5) aren't too bad, but there is still a little vibration at various speed settings, which would indicate it's the VFD not being setup quite as it should. I did find that the TaperLok pulley isn't running quite true, but don't think that's all of my problem. So I'll have to press on trying this and that. Bernard.

|

| Muzzer | 26/05/2016 19:08:38 |

2904 forum posts 448 photos | Can't help wondering if it is actually a mechanical issue with the motor, like a loose / damaged fan or something rattling around inside? Is this a Totally Enclosed Fan-Cooled (TEFC) motor with a fan on the end under a cowling or is it open frame (air passes through the middle of the motor)? There may be a reason why it has been discarded(?) yet looks almost new.... Frequency skipping is designed to avoid operation close to a resonance but this sounds more like an intermittent event. If it's something flapping about, it won't matter much what you do to the settings. Have you got another spare motor you can connect up quickly? Can you have a look inside the motor or under the cowling if it has one? You say the other motor seems fine with the same inverter. |

| Bernard Wright | 26/05/2016 19:31:11 |

90 forum posts 16 photos | Hi Muzzer, I've had the rear cowl off, because it sounded as though the fan was catching, absolutely nothing wrong there, did push the plastic fan on a bit further just in case, but no difference. I have tried very slowly increasing speed and there are good spots and bad spots, it is very definitely a frequency thing, at lower PD041 settings (1-2), the motor shaft appears to not know which way to go at a very low speed setting If it were something loose surely it would manifest itself all the time, the other motors are too inaccessible to try on the bench. The one in the miller seems fine with the same VFD settings, but it is really solidly mounted in a very large beast of a machine, I just wouldn't hear or feel anything from it. The Pillar Drill is a bit like the lathe for its motor mounting, i.e. on a swing plate against a spring to take up belt tension, it has its own issues, pulley a bit out of kilter, will get round to that eventually. So I'm left with trying a new pulley on this motor tomorrow, and going through all the VFD settings I feel relevant, now I'm getting into playing with it. Bernard

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

. Like you, I ran my motor on the default settings of 1440 and 4 poles for a while before realising they needed to be changed to 2880 2 pole, with no apparent change in how it performed. Also like you, my belts are long, maybe a bit longer than yours - you might want to check they are not too tight as that can cause them to whip just as much as if they are too slack. Also check the pulleys run concentrically and haven't suffered from corrosion in the vee - mine had in one spot because it had been stood idle for a long time.

. Like you, I ran my motor on the default settings of 1440 and 4 poles for a while before realising they needed to be changed to 2880 2 pole, with no apparent change in how it performed. Also like you, my belts are long, maybe a bit longer than yours - you might want to check they are not too tight as that can cause them to whip just as much as if they are too slack. Also check the pulleys run concentrically and haven't suffered from corrosion in the vee - mine had in one spot because it had been stood idle for a long time.

Register

Register Log-in

Log-in