Member postings for _Paul_

Here is a list of all the postings _Paul_ has made in our forums. Click on a thread name to jump to the thread.

| Thread: shaper motor |

| 13/11/2013 11:47:03 |

You could run it on an RPC which should be cheaper to make than the cost of a 3HP Inverter, that said the inverter will give variable speed and a lovely smooth finish. As a comparison my Alba 1a has a 1/2hp 3Phase motor and can produce a really smooth finish. My Elliott 10m has a 3/4hp single phase and will not produce the same quality finish no matter how much I tweak the setup/tooling/lubricant. Similar behaviour from both my single phase Boxford 8" and 7" Atlas. Regards

Paul

|

| Thread: Old hacsaw blades |

| 11/11/2013 01:05:59 |

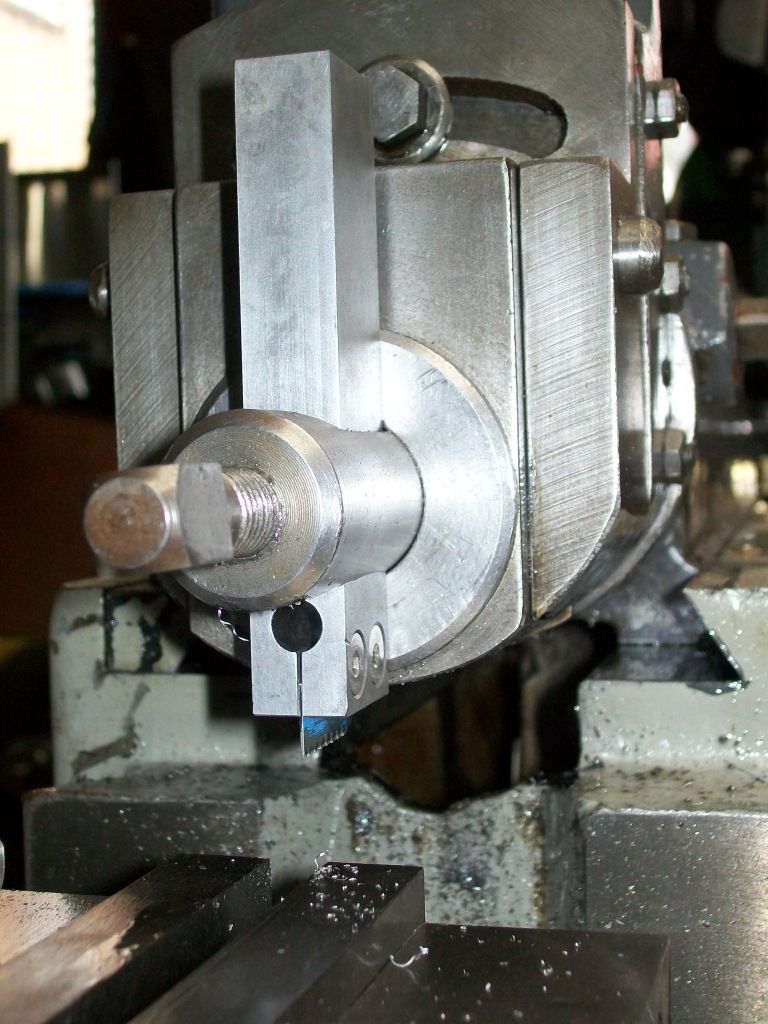

I use any good bits in my Shaper Slitting Saw:

Paul |

| Thread: What did you do today? (2013) |

| 27/10/2013 20:10:18 |

Bandsaw belt tensioner, any one who has one of these probably already knows how crappy the drive belt tensioner is here is my simple but effective modification. Also fitted an automotive drive belt in place of the Yak hair coated chewing gum item that was fitted.

Paul |

| Thread: What's it worth? |

| 23/10/2013 22:01:35 |

I was offered a complete early machine like this last year for £80, this one looks like it's missing the bits at the back that elevate the knee.

|

| Thread: What did you do today? (2013) |

| 19/10/2013 13:42:04 |

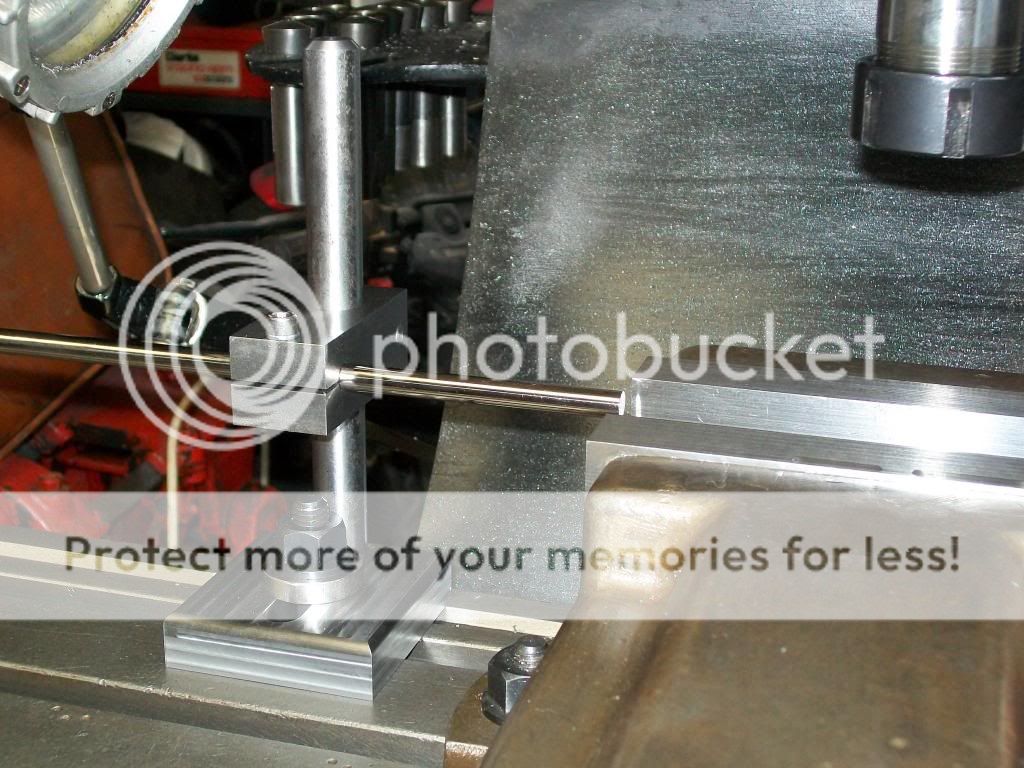

Started the conversion of my BS0 Dividing head to stepper operation:

Shows the adaptor shaft which goes from the dividing head worm which has a 1/2" shaft with two flats to 10mm for the stepper coupling (not decided which type yet) and the stepper threaded mounting and tube.

What it looks like fitted up temporary for measurement purposes.

Paul |

| Thread: Hemingway Discounts |

| 18/10/2013 01:48:54 |

Hemingway are not attending the Midlands show so are offering discounts of 10 and 15% until next Friday October 25th Hemingway |

| Thread: What did you do today? (2013) |

| 06/10/2013 15:08:07 |

Made some tee nuts, replacements for those that "evaporate" the ones in the background are commercially made of "foreign" manufacture. Just need to case harden and all done.

and what they were made from a bit of EN1a

Paul |

| Thread: Knurling tool - which one to buy |

| 06/10/2013 09:56:34 |

Posted by Bogstandard2 on 06/10/2013 09:06:34:

Knurls can also be used to 'expand' a piece of material for force fitting into a hole. John Another example of knurling use was the Piston ring manufacturer Cords who aside from manufacturing composite piston rings for petrol engines to reduce oil consumption used to also offer a "Micro-knurling" service for your pistons in an effort to address worn piston "slap".

|

| Thread: What did you do today? (2013) |

| 05/10/2013 18:19:48 |

Really nice piece of work Jason. Heres something slightly less ostentatious, I changed the vice on my BP so used the opportunity to make a new stop.

|

| Thread: Home brew DRO |

| 05/10/2013 17:57:49 |

Posted by John Stevenson on 05/10/2013 12:00:07:

Just a quick reply, gotta shoot up to Machine Mart to get some castors, the wheel has fell off the pram. The project is just a small part of a larger project that controlled a very expensive camera system and was paid for by a customer. I got the right to distribute the simple rotary axis part. I post later tonight in depth but I can share all the files. Probably put a new post up later.

Paul, The Nano or Uno [ both do the same job ] has a USB cable in one end which feeds 5v and signal to the Nano Other end has 3 wires coming out step, direction and ground to go to a stepper driver. As I say I'll post more when I'm welded the the armchair tonight. John, that would be much appreciated. Apologies to the OP for the partial Hi-Jack. Regards Paul |

| 05/10/2013 10:29:14 |

Posted by John Stevenson on 05/10/2013 00:39:42:

I have a Nano to run a rotary table. This is programmed from a laptop and then the laptop is used to run the rotary table, bit of a cheap mans division master and other than soldering a few wires on it's a simple build. John, A question if I may: how is the Nano connected, direct to the stepper? Regards Paul |

| Thread: Why is this site so negative ? |

| 04/10/2013 09:24:11 |

The wheels on those things made great trolleys when we were kids Edited By _Paul_ on 04/10/2013 09:26:37 |

| Thread: Knurling tool - which one to buy |

| 03/10/2013 13:19:31 |

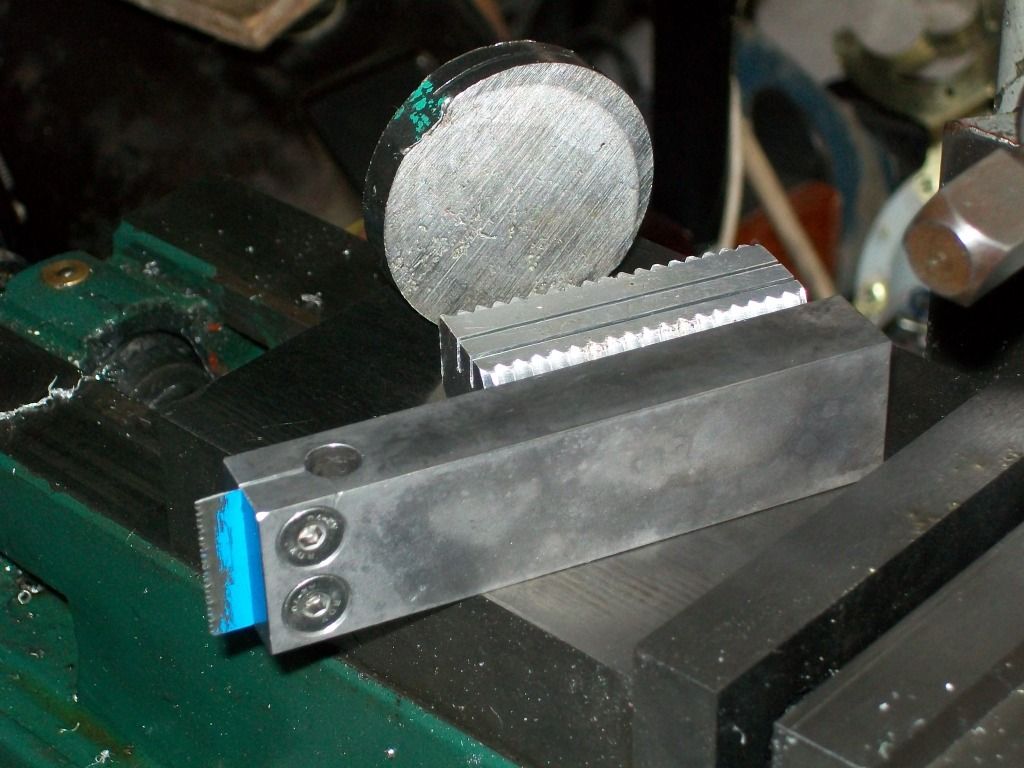

I built mine from scratch in around 4 hrs or thereabouts a bit at a time as the parts/materials came together.

Examine/zoom the knurling on the handwheel thats the quality it will produce. Here is what you get in the Hemingway kit |

| 03/10/2013 11:44:47 |

I have a home brew copy of the Hemingway kit produces very good results, as clamp type Knurlers go IMHO the smaller scissor type tend not to produce a very good pattern. If you can try to get or make something substantial. Graham thats a very elegant design, does it self centre? Regards Paul

|

| Thread: Bridgeport 2j |

| 25/09/2013 20:40:56 |

I have good success with synthetic Tractor paint quick drying, rollable/brushable & oil resistant try Smith & Allen. T68 slideway oil for the machines ways and Velocite for the spindle, it it's been greased by a previous owner best of luck cleaning out the grease you could end up taking the table off. Does the machine have a panel on the back? if so tank acces is through that. Paul

|

| 25/09/2013 19:20:06 |

The machine has what appear to be "manual" oil nipples on the front of the saddle so it may never have had an oil system, I have seen some examples like this over on PM. Thinners on a bit of rag should shift the clag but will also shift paint, are you going to paint it? Paul

|

| Thread: Lathe tool rack |

| 24/09/2013 19:55:06 |

Does it have to go on the splash guard? I have this screwed to the head of my Boxford, reach up grab the new toolholder swap over and done with no reaching over the work.

|

| Thread: Slideway Oil |

| 24/09/2013 19:45:26 |

Paid a visit to the "Baltic Oil Works" In Newport today for some T68 slideway oil, 20 litres for just under £90,,,, or does anyone have a cheaper supplier?

|

| Thread: What did you do today? (2013) |

| 24/09/2013 19:27:32 |

You can never have enough toolholders.

|

| Thread: Hardinge UK.....agh! |

| 23/09/2013 02:12:07 |

Not tried Motion Components yet but noted for the future. Our local bearing supplier Hayley (Wales) had "trouble" with the difference between bearing standards and tried to palm me off with a C3 insisting it would be OK....the one fellow there also tried to blag me saying if it has no markings it's a "standard fit" bearing same as a C2.... you can see why I dont go there very often..... The 6206 C2 bearing is listed as an RHP on the Hardinge site at £18 + shipping and VAT, what eventually turned up was an SKF so I could have bought from Motion and saved a tenner and possibly the wait..... it gets worse. I never gave Ketan a thought for this, I have noted though that he sells some "unusual" Magneto bearings, I will ask him the question next time. Thanks Paul |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in