Member postings for JasonB

Here is a list of all the postings JasonB has made in our forums. Click on a thread name to jump to the thread.

| Thread: Tramming your mill(/dril) head:A theoretical question-Idea came up |

| 02/10/2023 11:13:30 |

My thinking is that I use the mill with minimal quill extension when cutting so that is the best way to check the tram, as Graham says it may well be different when extended so why test it in that position. Even having the quill free or locked is likely to affect readings, so test it as you are likely to use it would be my way of doing things. |

| Thread: Which thread is recommended, please? |

| 01/10/2023 13:39:37 |

Even then you can get smaller hex metric fixings which I use all the time or just make your own if commercial is not to your liking |

| Thread: Tramming your mill(/dril) head:A theoretical question-Idea came up |

| 01/10/2023 07:38:10 |

Posted by Greg Webb 1 on 30/09/2023 18:56:11:

If the jig was a tube without any angle, would finding the centre at the base and then at the top by moving the quill up give a difference if the head was not trammed. You then start to get into the realms of which do you tram, usually the spindle axis is trammed to th emill table but there is also colum to table and quill movement to table to be considered which may show* * however it still comes down to showing tiny deviations over a short distance that you would be hard pushed to see. As Pete says even with perfect tram you may get slight back cutting as the front pass may deflect the spindle slightly upwards and also cause minute flex in the machine particularly if your facemill has the blunter inserts which means that as the deflection and movement is removed once the front edge has cleared the work the tool drops down and takes a skim on the trailing edge |

| Thread: Which thread is recommended, please? |

| 01/10/2023 07:26:18 |

Looking at the Chart Michael links to there is really very little difference between what it shows for the thread sizes you are likely to find on a clock say M1.6 to M6 all pitches if you pro rata them to what is shown they are within 0.1mm mostly 0.05mm Add to that as Foggy say you can get several pitches if you need something finer than the standard coarse pitch and I see little point in using BA, only real reason may be that 2, 5 and 7 work well on fractional imperial stock but as metric is easy to find these days not an issue. Tooling is also more plentful in metric with choices in types of tap etc |

| Thread: Upgrading from a Clarke CL300M, where to go? |

| 01/10/2023 07:16:08 |

The 290 machines come with 150mm chucks so no problem, not sure what the smaller 7x machines with big bore spindles have |

| 01/10/2023 06:52:15 |

As Bazyle says Warco tend to include 3 & 4 Jaw chucks, fixed and travelling steadies, faceplate etc. Others including Amadeal only supply the 3-jaw so that can make several £100 difference. Then there can be differences that are not so easily seem such a scontrol boards, some make smay use American ones, other far eastern which may have lower grade components As for screwcutting it really depends on how much you need it. I may only use it once a year so it was not a deciding factor when I bought my Warco 280 but if you feel you are going to do a lot then it may be higher up your list of wants My prevous Emco was a geared head machine but I'm mor ethan happy with the variable speed I have now and would not want to back to having to keep stopping to change to one of th elimited range of speeds Edited By JasonB on 01/10/2023 06:53:33 |

| Thread: Quick release indicator holder |

| 30/09/2023 19:52:15 |

Better still embed it |

| Thread: Tramming your mill(/dril) head:A theoretical question-Idea came up |

| 30/09/2023 18:42:56 |

Chris, try putting a 0.1mm or 4 thou feeler gauge under one side of your jig and see just bt moving the X and Y you can get the coax to show zero, I think iy will still show zero as the difference between flat and shimmed is 0.000032mm which is 1/3rd of a micron you you will never see with the naked eye |

| Thread: Brass plate or flywheel casting |

| 30/09/2023 07:18:56 |

I've built a couple of engines for a guy in near Skibbereen and he also says it is hard to get anything for when he builds the smaller engines |

| Thread: Digger |

| 29/09/2023 19:28:25 |

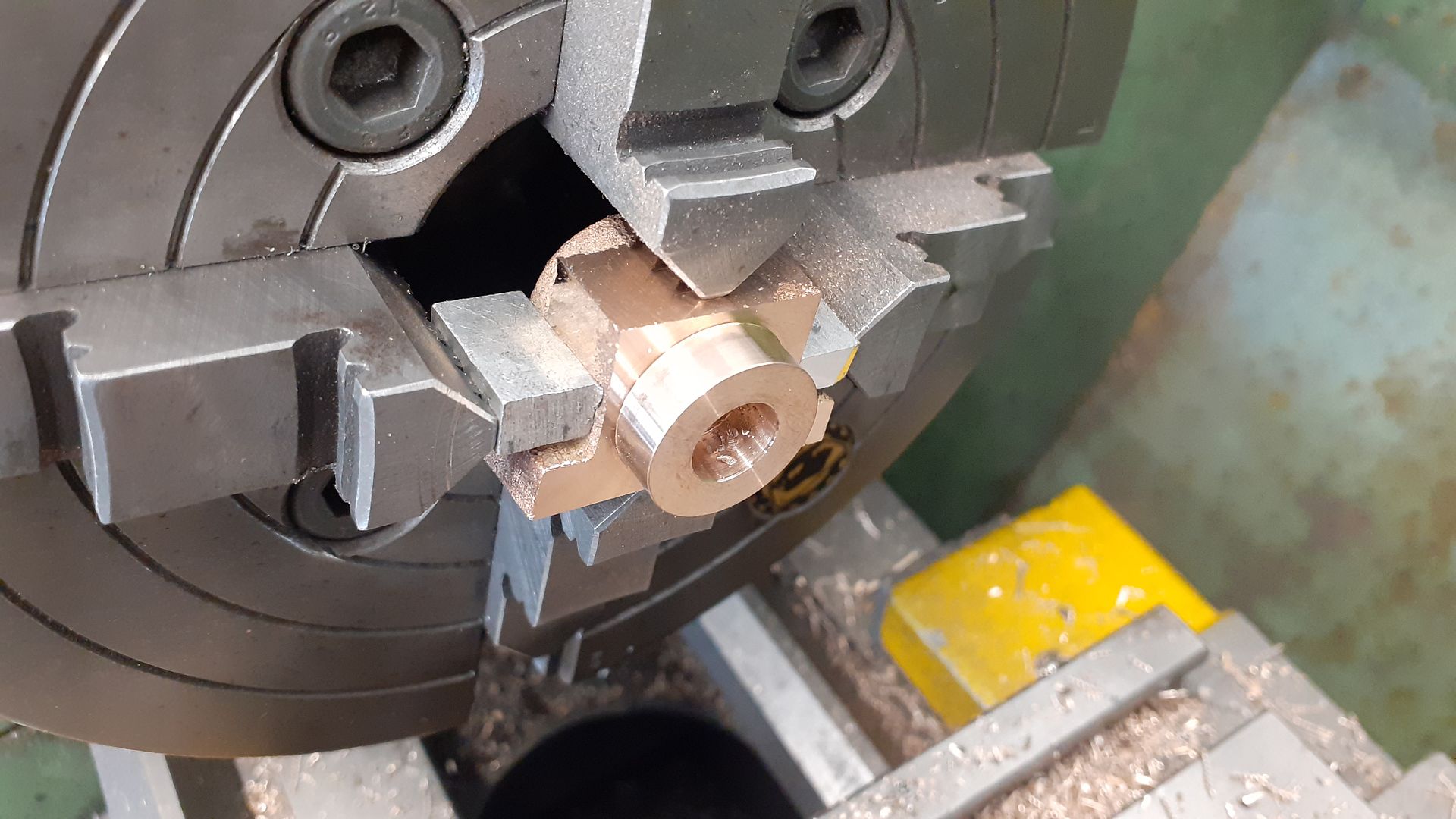

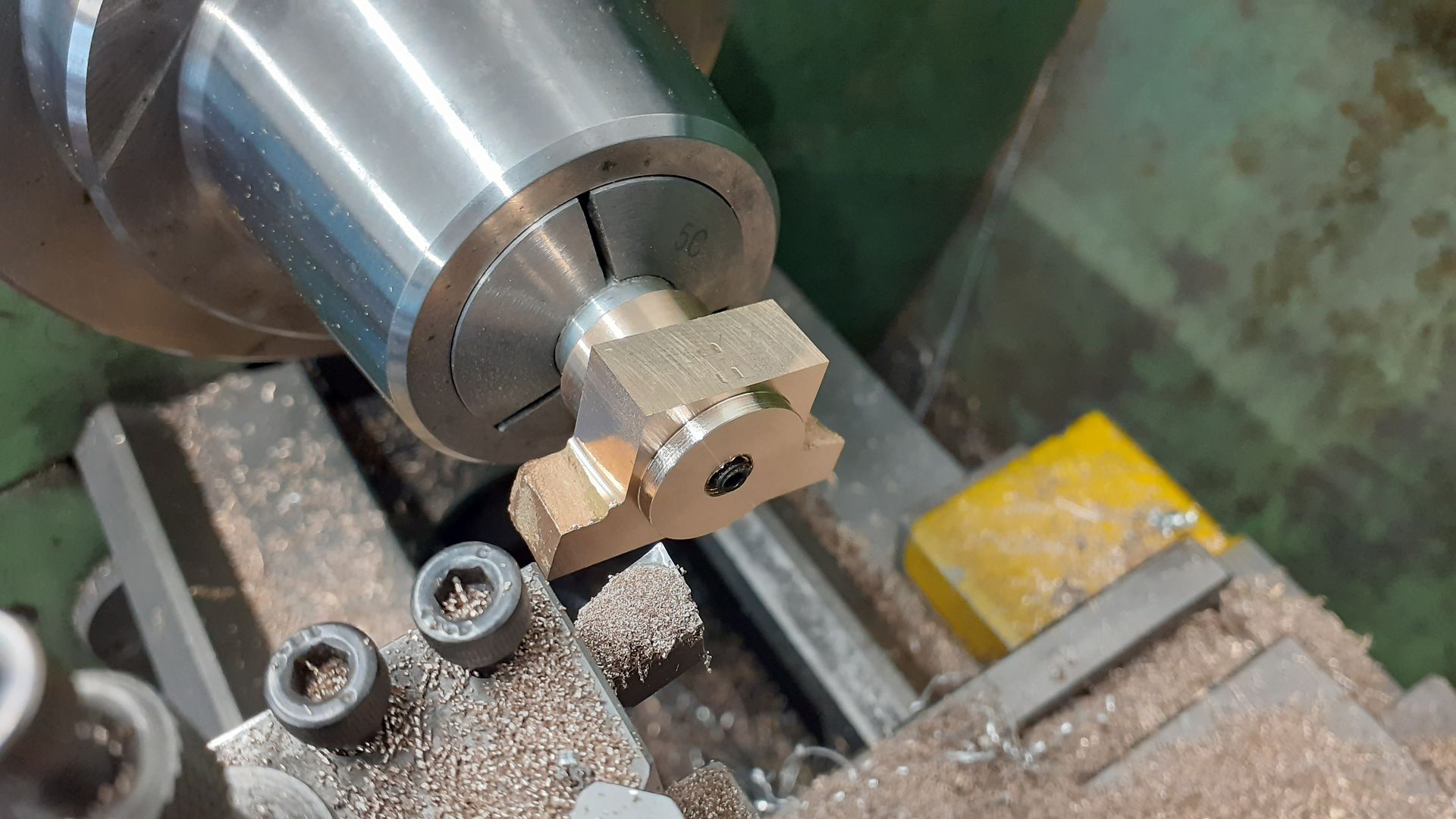

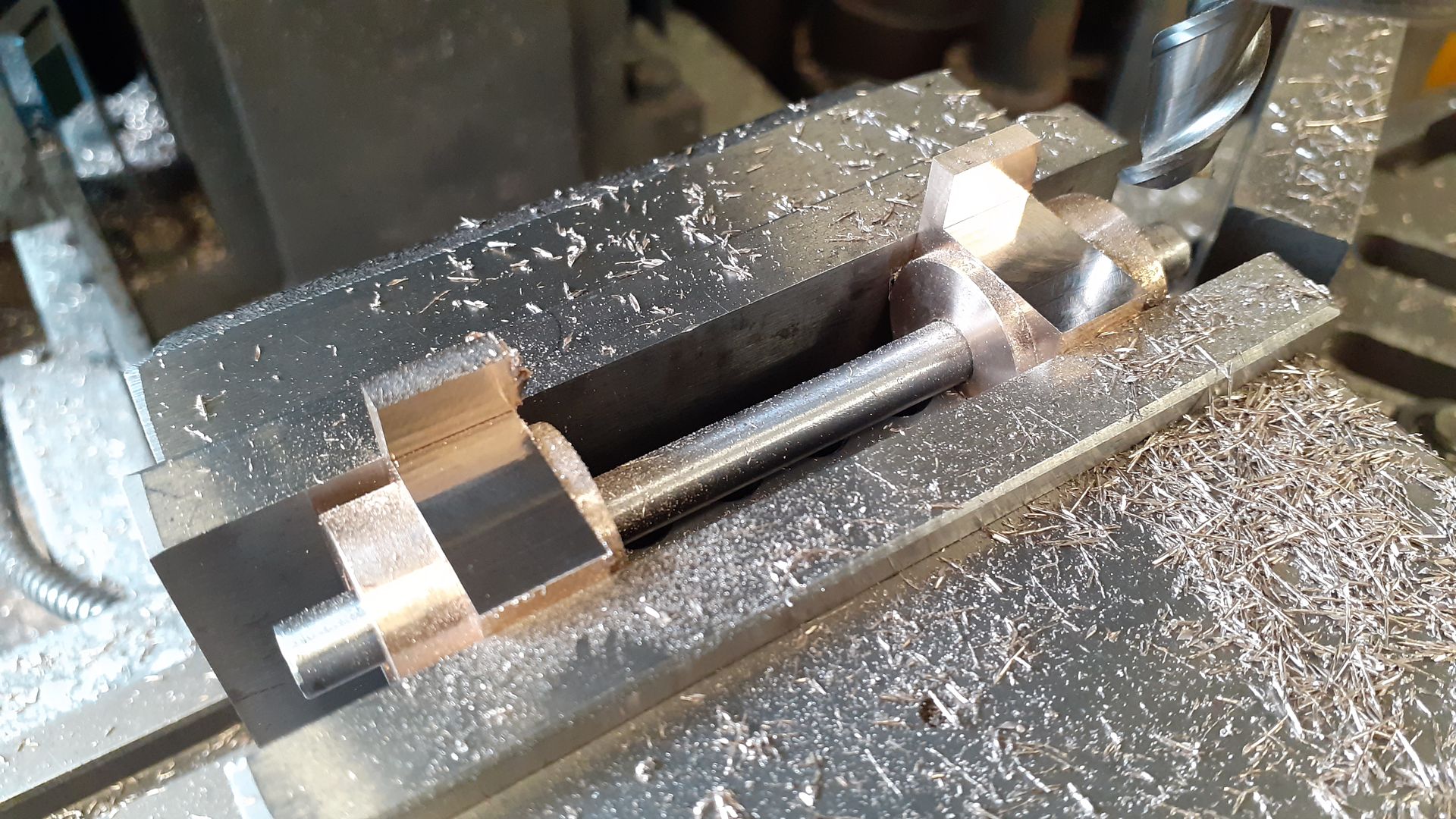

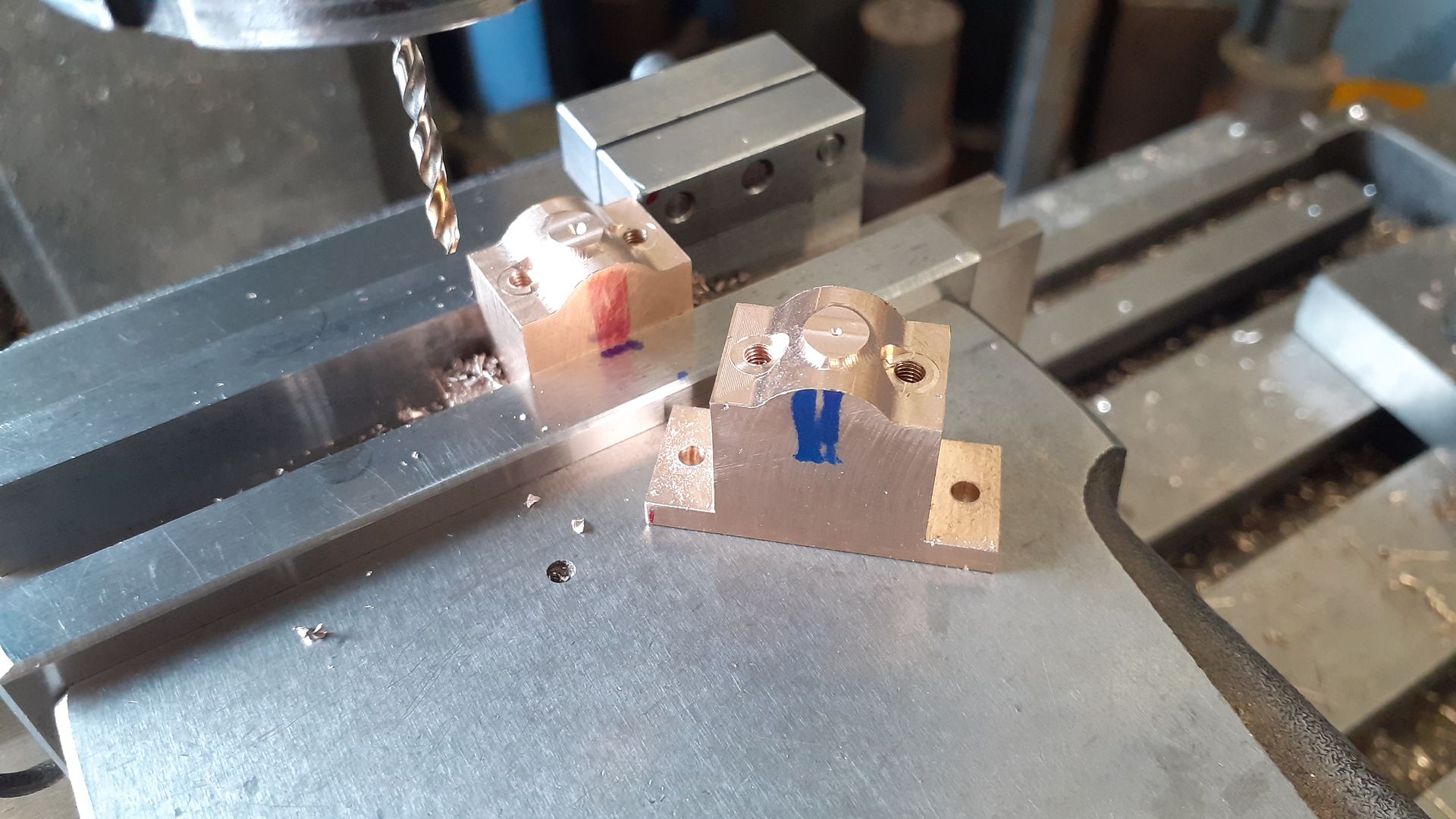

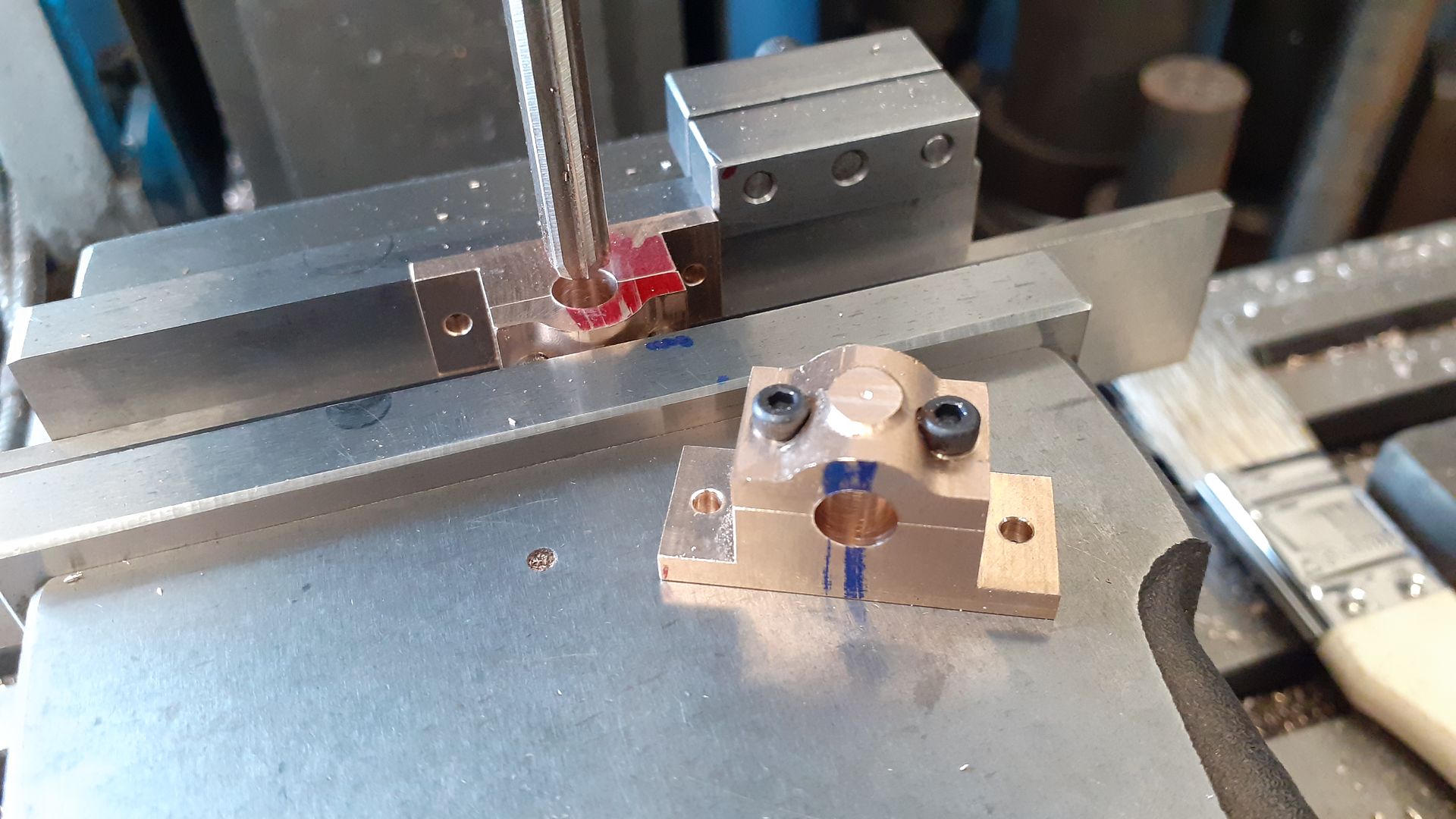

The cylinder pivots in two trunion bearings, I made a start by skimming the top, bottom and two side to get rid of the draft angle and was then able to close up the chuck jaws on these now flat faces, the sides needed a packer as the foot would have got in the way of the jaws otherwise. The 3/4" dia x 1/4" long outer spigot was turned, a 1/4" hole reamed right through and then counterbored 3/8" for the packing gland. Just like the milling I'm using CCGT polished and ground inserts for non ferrous metal here and did for just about everything lathe operation on this engine. |

| Thread: TCMT VS CCMT |

| 29/09/2023 16:07:13 |

I find I tend to make more or less equal use of both maybe 60/40 in favour of the facing one. So maybe think about getting that first and see how you get on. I find I can more or less keep up with using all my inserts on all four corners having the two options, if it were just for facing then I'd probably start to build up a backlog. I also find the fact that the other two "unused) corners being over 90deg are a bit more durable so ideal for castings or other irregular work |

| 29/09/2023 14:03:57 |

Plenty of other suppliers other than Glanze, Mine were JB Cutting tools, look for SCBCR and SCBCL such as the ones from APT Not sure why Clive's one can't easily be used for facing, could be as his are pin location rather than the screw location I have and why my codes start with S for screw .this is mine in action Edited By JasonB on 29/09/2023 14:15:13 |

| Thread: Brass plate or flywheel casting |

| 29/09/2023 13:48:50 |

Any reason you can't use a slice of round bar? Someoen like M-machine may well be happy to cut you a thin slice from square or round brass but you may have to pay a small premium over the typical 1" length increments they generally sell by, drop them an e-mail. If you can use something other than brass then a Stuart Progress flywheel casting can be bought from them, look under spare parts. |

| Thread: TCMT VS CCMT |

| 29/09/2023 11:18:38 |

With the right holders all 4 corners of a CCMT can be used |

| Thread: DROs etc |

| 29/09/2023 10:56:37 |

Looking at the mods you have done the magnetic tapes could simply be stuck over the engraved scales you already have. You then only need to make provision for the mini encoders. The X encoder could be mounted to the left of your stop and the Y take the place of the pointer and it's rod that you have. The stop clamps could just be modified to clear the tape if you still wanted to be able to us ethem.

Edited By JasonB on 29/09/2023 10:57:34 |

| Thread: London Model Engineering exhibition at Alexandra Palace |

| 29/09/2023 10:19:58 |

Guildford is now a lot smaller than it used to be and is more just an open day for the track. Insurance and marquee hire became too great for the club to risk it as poor weather would reduce the gate and they would make a loss. That is another issue for the likes of Ally Pally, being in January could put it at risk of snowy weather which would again keep numbers through the gate down and with higer costs for the organisers the risk of a loss is far more than one this time of year in a venue they own. Having Model engineer and teh London show around the same time of year was never going to help as people either visited one and not the other or if they visite dboth only had the same amount to spend over the two shows so half the possible sales for the traders who still have to pay to attend both shows. As Benedict has shown in his other DRO thread with people taking the chance to buy direct from the far eastern selling sites that too has reduced sales for the UK suppliers so even less income likely from attending an ever more costly show. Can't really complain about a lack of shows if you don't support those attending. |

| Thread: Tramming your mill(/dril) head:A theoretical question-Idea came up |

| 29/09/2023 07:36:03 |

Just sketched it out in CAD If we assume the widest point of your cone would be 65mm dia then applied the equivelent change in shape corresponding to 0.1mm over 100 of tram error you would be looking for 0.000032mm on the coax. One is easy to read the other you won't read. Given that most would want something like 0-.01mm or better over 100mm then you will never see th eneedle move on the coax I drew it as a cylinder, sliced the top off a 0.1:100 (0.06deg) and then measured the major axis of the elliptical end. You can also see from the Y delta that by measuring over 65mm dia even if done the traditional way your reading will be smaller, half of less of what can usually be swung across a mill table. |

| 29/09/2023 06:53:51 |

If you were to work out the effective major and minor axis of the elliptical shape that teh Coax may follow iff the tram were off by say 0.1mm/100mm it would be such a small difference that you would not be able to measure it with the usual dti scales on these coax indicators You would also need to ensure your piece of bar had the end facing the chuck completely true to the cone, I did not see mention of even facing it. |

| Thread: Steel Boiler Manufacturers |

| 28/09/2023 15:07:51 |

Have a look at this particularly last post |

| Thread: 5 minute cad |

| 28/09/2023 15:03:06 |

It's a closed group so I'll resist joining to avoid spending too much time there. I just had a look and F360 will produce code for Proto TRAK conversational which sounds like what he has so could go either way. |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in