Member postings for JasonB

Here is a list of all the postings JasonB has made in our forums. Click on a thread name to jump to the thread.

| Thread: *Oct 2023: FORUM MIGRATION TIMELINE* |

| 03/10/2023 17:02:21 |

You may see a few new topics and posts under those topics in the next day as a couple of things want setting up before this site is closed. Please just ignor them, most likely to be locked anyway. |

| Thread: Test thread for posting links |

| 03/10/2023 16:47:13 |

. |

| Thread: Test thread for inserting gallery image or file |

| 03/10/2023 16:45:55 |

. |

| Thread: Test Thread for using Quote |

| 03/10/2023 16:44:17 |

. |

| Thread: Test thread for inserting video eg Youtube |

| 03/10/2023 16:42:38 |

. |

| Thread: Test Thread for inserting images |

| 03/10/2023 16:41:06 |

. |

| Thread: Test thread for posting a reply |

| 03/10/2023 16:40:19 |

. |

| Thread: Comments (constructive) on the New Forum Software |

| 03/10/2023 16:39:06 |

. |

| Thread: New Forum Software questions not in Help/FAQs |

| 03/10/2023 16:38:12 |

. |

| Thread: Cutting Small Internal Keyways |

| 03/10/2023 15:42:07 |

If you ae going to be doing a few then a cheapish broach and home made bush would be the answer I push 1/8" wide through without a press but anything bigger really needs one. I bought a set of three - 1/16, 3/32 and 1/8 plus some bushes and they have seen a lot of work and been borrowed too. |

| Thread: *Oct 2023: FORUM MIGRATION TIMELINE* |

| 03/10/2023 11:32:57 |

I hope you think so Howard We have been using a Mortons URL for testing but I think the existing one is likely to be used as it easy to search but passwords remembered in your device may not carry forward. One other thought, classifieds will not carry over so if you have typed a long description for an item then copy it so you can past it into a new classified. |

| Thread: Cutting Small Internal Keyways |

| 03/10/2023 11:04:50 |

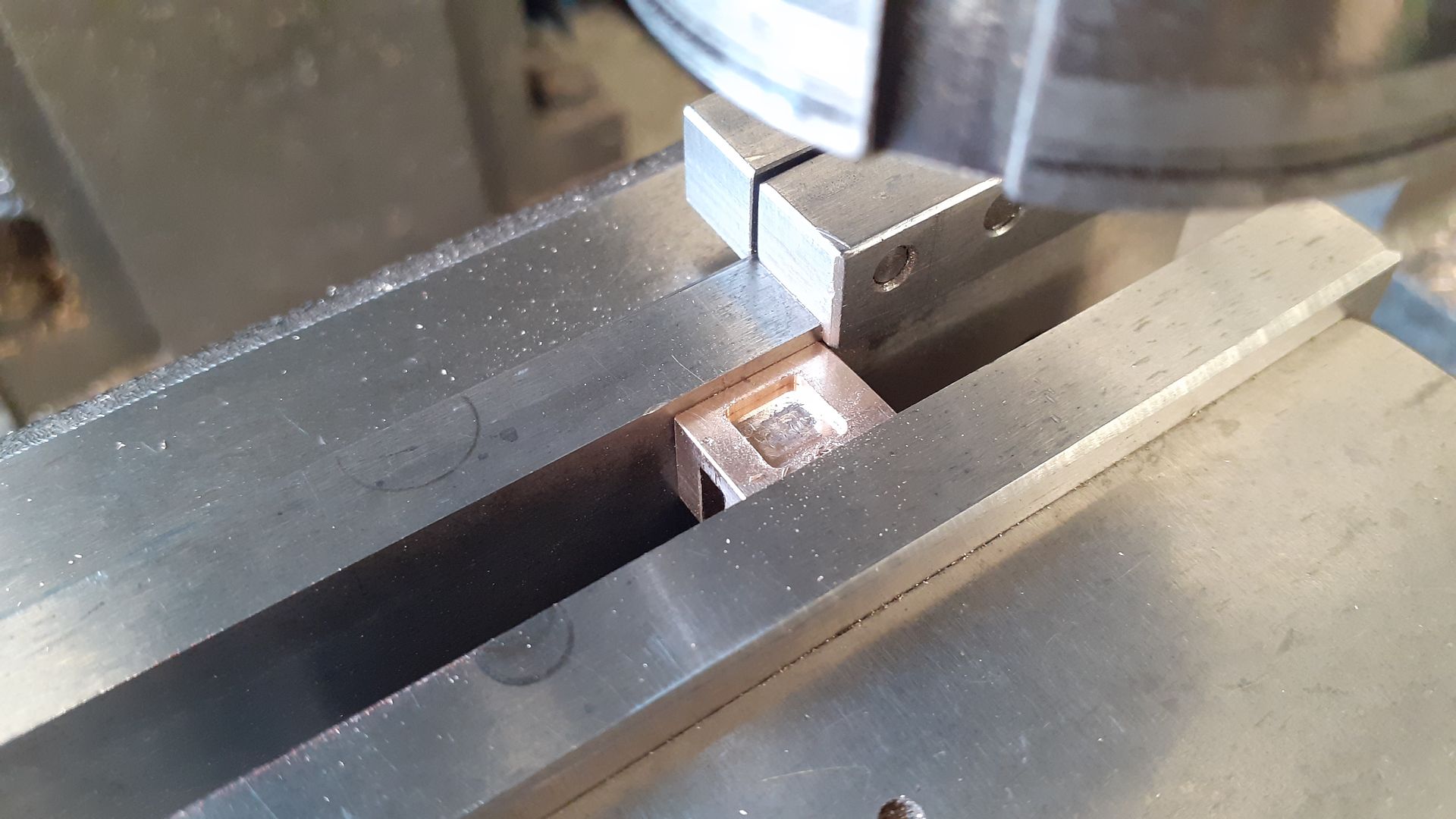

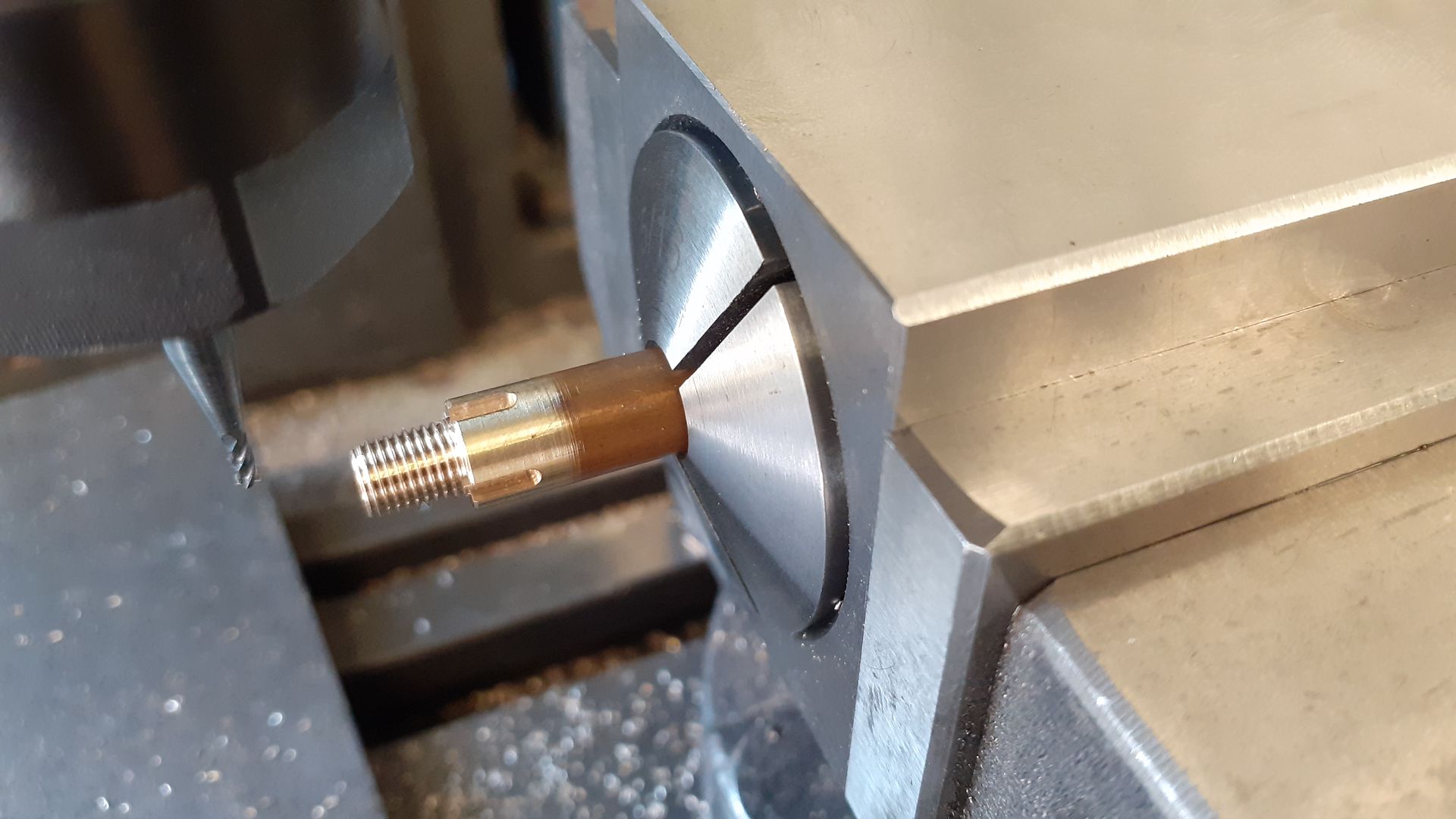

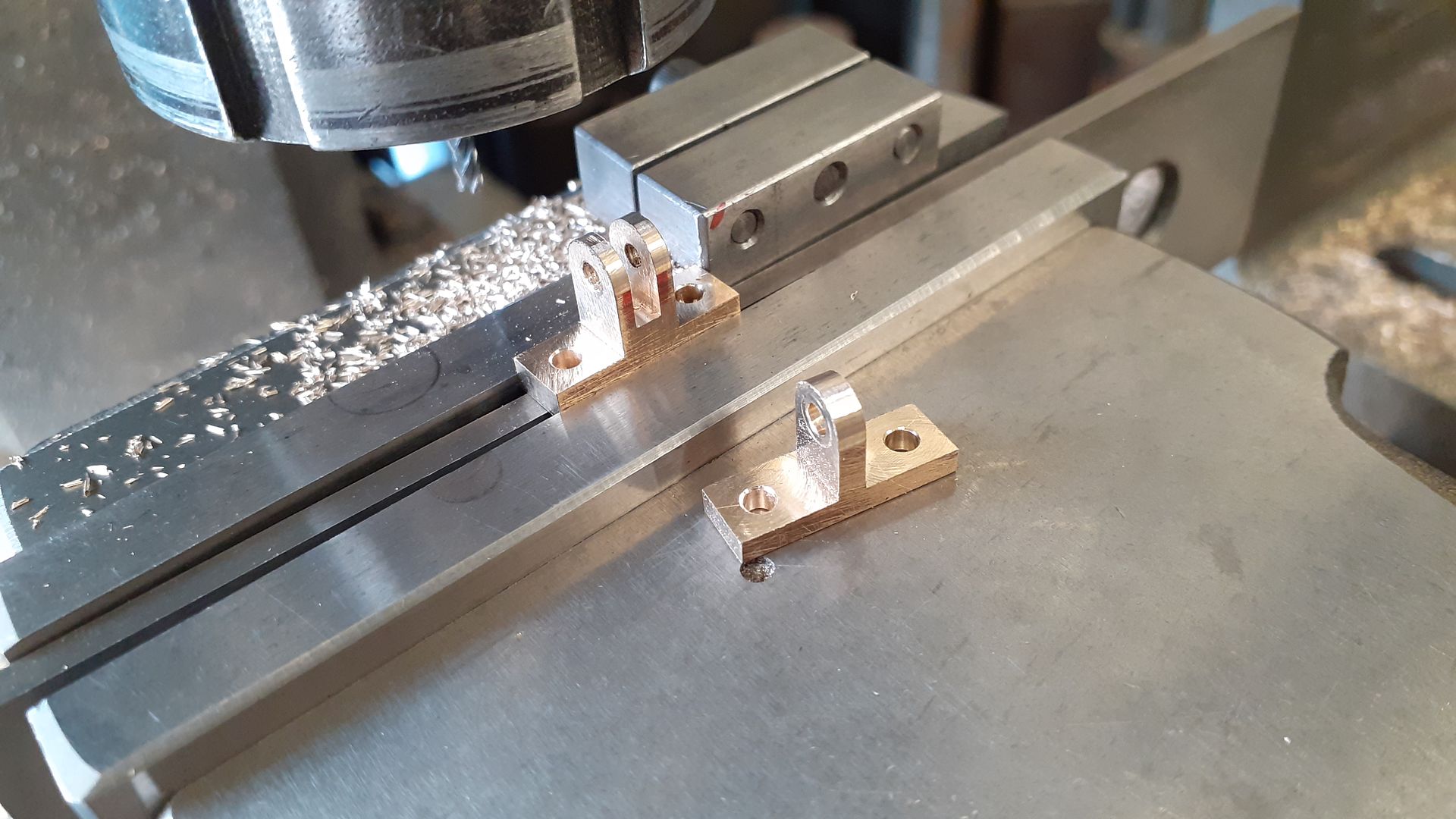

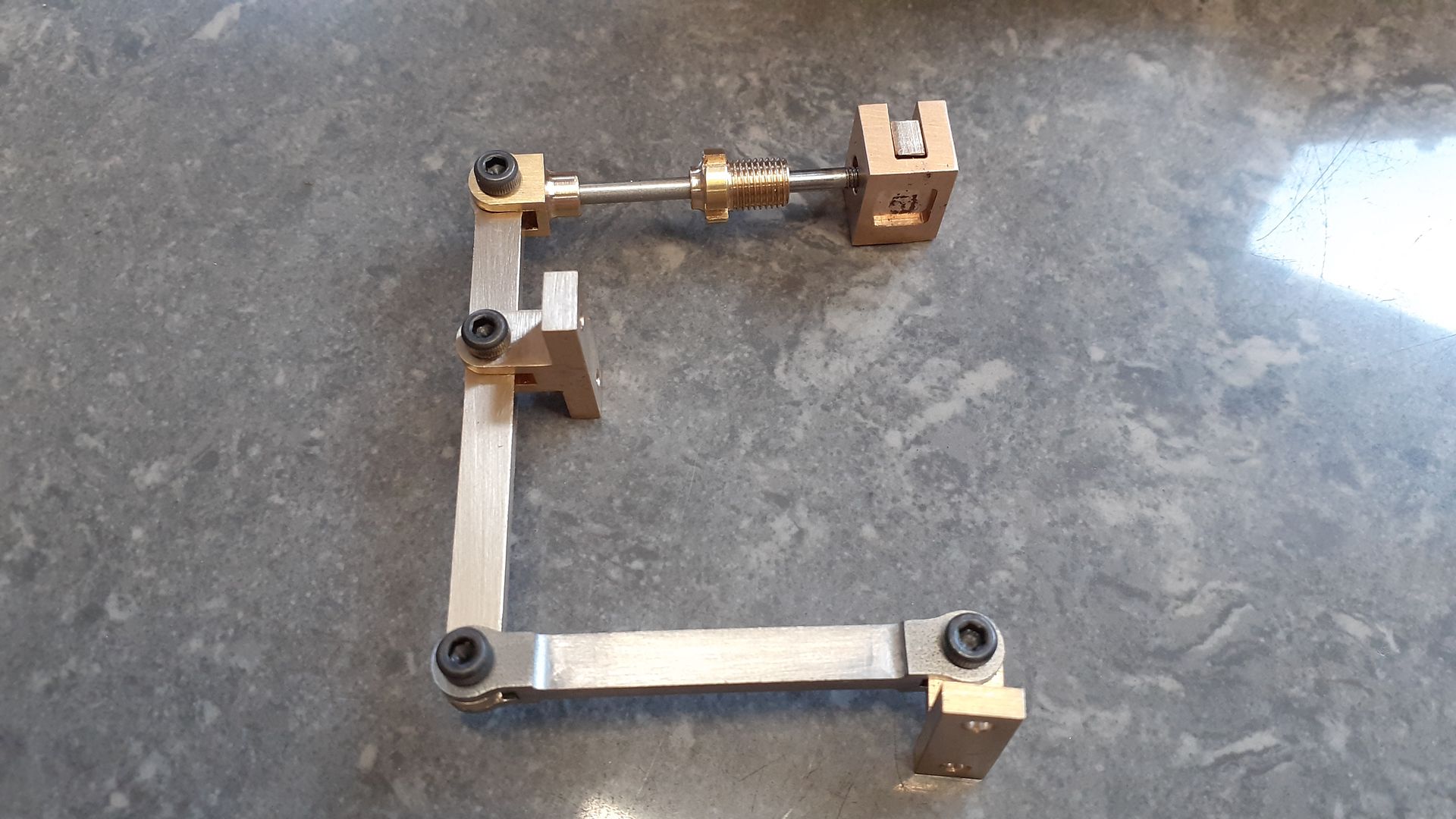

Nigel this is the adjustable sort I was talking of where the long cutting tool pivots and can be pushed out by a grub screw. I just use a smaller dia shank and an HSS bit at right angles

Very similar concept to what a modern CNC machine will use just moving thetool up and down while slowly advancing the work

Or you can just mount a bit of square HSS in the toolpost and use that if metal is softer or length shorter

|

| Thread: What defines BILLET … |

| 03/10/2023 10:12:54 |

I always thought of a billet as a slice off a bar say a 1" thick slice from some 6" CI bar. But it has become the norm of anything machined from the solid as opposed to a rough casting or fabricated. The US users above use it to mean cut from solid, they would not use it for a machined cast aluminium component. So a billet engine block will be from a solid piece not a machined casting or a wheel will be from solid round stock not a casting or forging. |

| Thread: Cutting Small Internal Keyways |

| 03/10/2023 09:00:05 |

No Chris said "a couple of thou" no full depth. You can make tools that have a shank that fits the bore and a long tool that is pushed out by a grub screw to advance it but at 3/8" it is getting a bit tight to fit it all in. So by having say an 8mm or 5/16" shank and the tool sticking out almost all the remaining 1/16" you can put on a cut . 1/8" slot in a 3/8" bore is a bit wider than standard which is generally 1/4" the shaft/hole size so 3/32 would be usual for 3/8. Also 1" is getting a bit on the long side, I don't think standard broach bushes are that long but woul dneed to measure mine though I do make my own longer ones. I have done 1" long is steel @ 3/16" wide but probably used about a 5/8" shank tool into a 3/4" bore but it is a lot of work and needs many passes including regular spring passes, the one on the left.

|

| 03/10/2023 06:52:49 |

I've always had good resuls doing it by "hand" using the lathe carriage or mill's quill to feed the tool though now I mostly use cheapish broaches. Your advance a couple of thou may be the problem I find 1 thou is the most I advance the tool by somethimes less, it's a case of lots of very fine cuts which won't deflect the tool as much as larger ones will My usual tool is a boring bar type that holds an HSS tool at right angles that is ground like a zero top rake parting tool. Shank has always been smaller than the bore when using this type of tool so the cut can be put on. J PS how long is the slot? |

| Thread: Digger |

| 02/10/2023 19:27:59 |

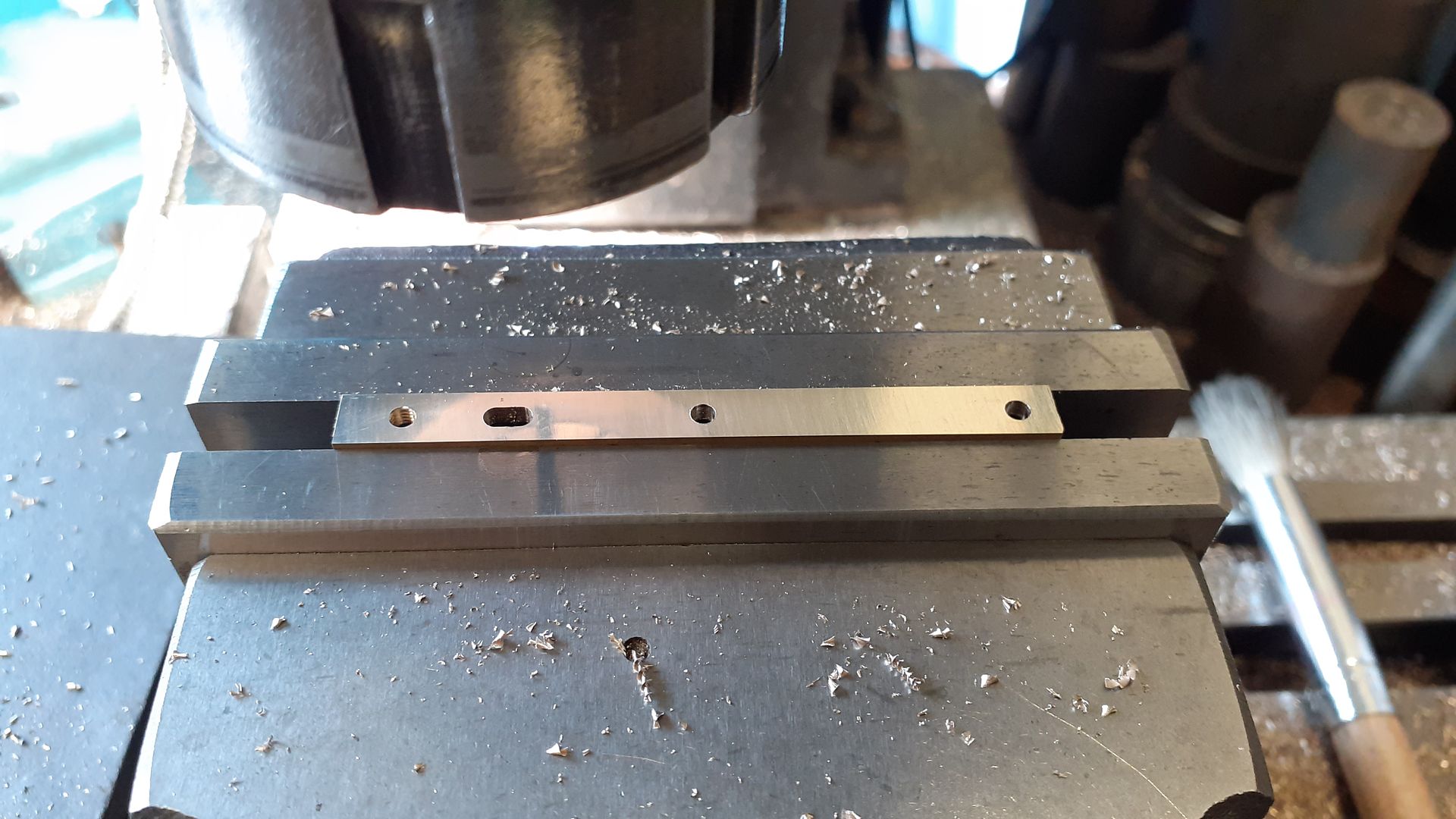

Rather then do all the big bits and then be left with the small fiddly ones at the end I decided to do a few of those. First was the slide valve for which a small casting is supplied, this was cleaned up all over and then the slot for the valve nut milled. Unlike a lot of valves which have a second slot for the valve rod this one has a hole which is a bit larger than the rod to allow the valve to lift if needed. |

| Thread: *Oct 2023: FORUM MIGRATION TIMELINE* |

| 02/10/2023 18:18:47 |

There may be those who have been members for many years and signed up with an e-mail that they no longer use or can access. So if you are going to need a new password sending to you it would be best if you can open th ee-mail it is sent to. If you go to settings and then "My Account" you will be able to see which e-mail the forum is usng for you You can also set a new password there if you can't remember your current one as password ssaved on your device may no longer work on the new system. |

| Thread: New member |

| 02/10/2023 13:56:24 |

I suggest looking at something around the SX2.7 size machine which will be a worthwhile step up from the SX1L and having the separate head raising screw avoids some of the backlash issues that the X2 siz emachine can have although the latest twin strut one does go some way to reducing that. |

| Thread: Dedicated Search Engine |

| 02/10/2023 11:35:38 |

I did try the new forums search and it came up with what I wanted part way down the 5th page. Google gave it to me as the first item so not so useless in my book |

| 02/10/2023 11:15:09 |

Some of us are having nightmares testing it |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in