Member postings for Ron Laden

Here is a list of all the postings Ron Laden has made in our forums. Click on a thread name to jump to the thread.

| Thread: My First Stationary Engine |

| 23/01/2020 19:05:53 |

Thanks Jason that is really helpful. Think I will go with an aluminium piston and try a pair of shallow V oil grooves. The drawing gives an option of either steel or aluminium for the flywheel as shown on the drawing, I was surprised as I thought it would be steel/cast iron and not aluminium or is alu easier to drive on a small engine. Regarding running I am about to get a new airbrush which comes as a set with a compressor (reservoir type) which is rated up to 30 psi, I am hoping that will be ok for driving the engine. Ron |

| 23/01/2020 14:23:33 |

Geoff, I had a look at your album some nice work there, did the engine run well..? I also see that J.D.W has changed the design of the flywheel, assuming yours was as per the book. Ron |

| 23/01/2020 12:55:38 |

Thanks Jason, appreciated. Ron |

| 23/01/2020 12:38:51 |

Thanks guys for the advice. Neil, I did wonder about the reamed finish for the cylinder but it is what the drawing listed, I can quite easily bore it. Ron |

| 23/01/2020 09:25:23 |

Posted by Russell Eberhardt on 23/01/2020 08:57:46:

Are you sure the o-ring is 1.5 mm cross section? The nearest UK standard size would be 1.6 mm. Tubal Cain recommends (in his Model Engineer's Handbook) a groove width of 2.3 to 2.5 mm and depth of 1.18 to 1.25 mm. The width is greater than the ring cross section to allow for the compression of the ring. I would start at the tighter end of the tolerances, try it, and adjust to get a good feel for the fit. Yes, silicone is good. Russell Hi Russell Looking at the drawing again the 1.5mm is actually the groove width with a depth of 1,25mm but there is no detail of the O ring size. Even if 1.5mm was available I can now see it would be too tight. p.s. Looking on Ebay Silicone 1.5mm rings are listed but I wonder if they are actually 1.6mm..? Thanks Ron Edited By Ron Laden on 23/01/2020 09:31:09 |

| 23/01/2020 08:16:16 |

I am taking a couple of weeks off the class 22, I need a machining fix I havnt done any work on the lathe or mill since before Christmas. I was going to make some tooling but then came across a number of online drawings for stationary engines. I didnt want anything complex or long winded so looked for something simple and found a Julius de Waal drawing of the Muncaster Simple Oscillating Engine, which although quite simple I do like the look of it . So I thought I would have a go and try and get it out of the material I have on the shelf, it will be 95% as per the drawing but maybe one or two cosmetic changes. Having gone through the drawing I am ok with the detail but I have a question re the cylinder/piston. The cylinder is brass with a bore of 16mm (reamed) and the piston is 16mm close fit but what does close fit equate to with a piston/cylinder..? Also I dont have bronze for the piston, I was thinking brass..? The piston has a 1.5mm O ring fitted into a 13.5mm diameter groove which leaves the ring protruding 0.25mm which seems a lot but will the ring compress enough to be ok..? Also there is no detail on the O ring material would it be silicone..? Thanks Ron |

| Thread: Product Descriptions (Up to scratch?) |

| 19/01/2020 08:17:17 |

Having had a mini lathe I think a couple of points worth considering is to go for one with a 100mm chuck, 400mm between centres and a 500 watt motor (ideally brushless direct drive) If I was buying one now it is what I would aim for. |

| Thread: Has anyone watched this Girl |

| 18/01/2020 09:34:07 |

Very impressed, she has a pleasant voice, speaks clearly and is obviously very skilled and a good teacher. Much better than a lot of teaching videos I have watched and excellent for the beginner. I have watched 2 or 3 of her videos and picked up some good tips and some good tool projects, will have to watch some more.

|

| Thread: What Did You Do Today 2020 |

| 17/01/2020 06:26:47 |

That's impressive Andrew especially with it in 3mm steel and having shallow flanges, can't have been that easy to do. Looks very good. |

| Thread: The Workshop Progress Thread 2020 |

| 16/01/2020 07:50:05 |

I read yesterday that the production of the original MAPP gas ceased in 2008.

|

| 15/01/2020 07:03:34 |

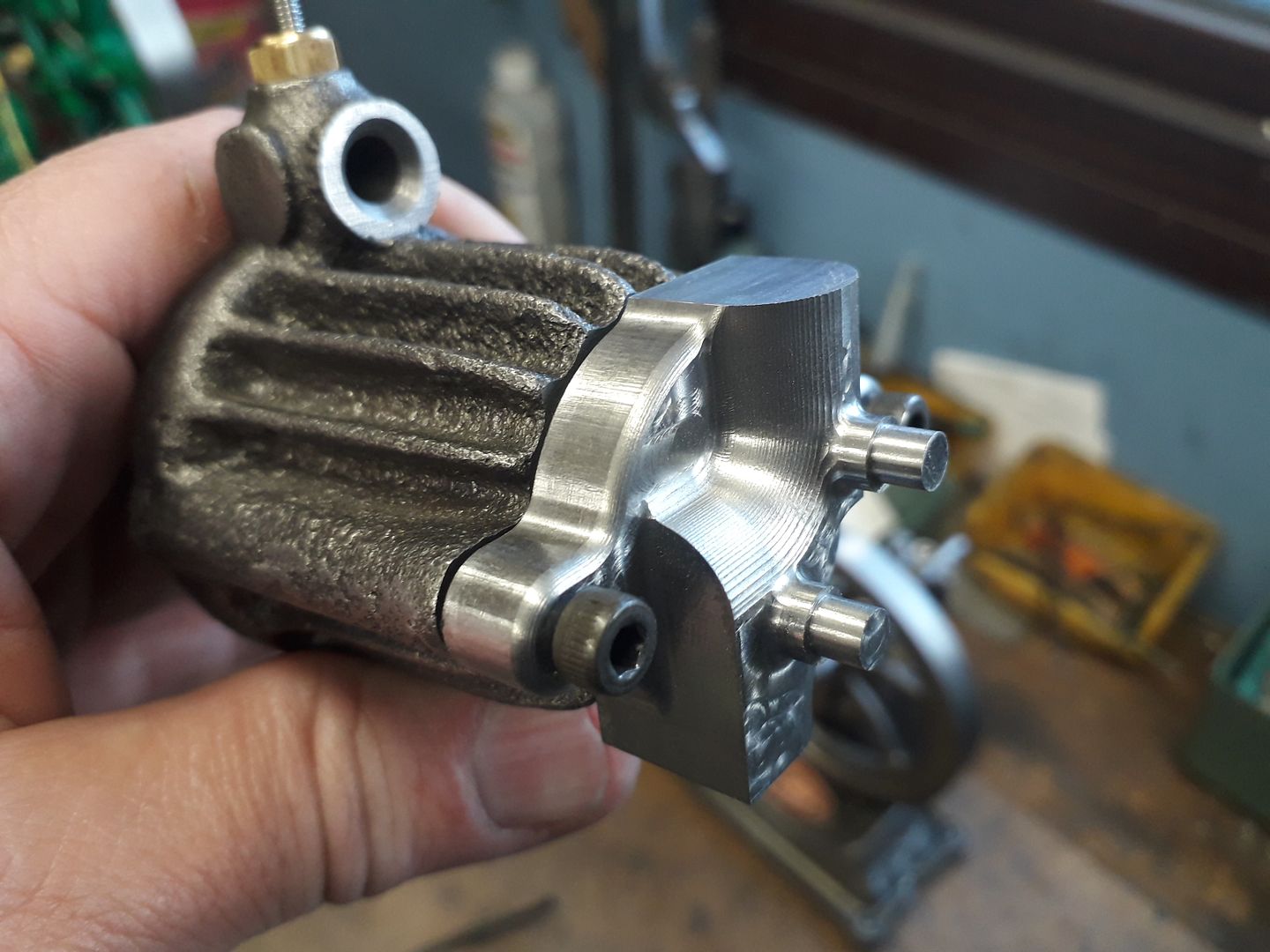

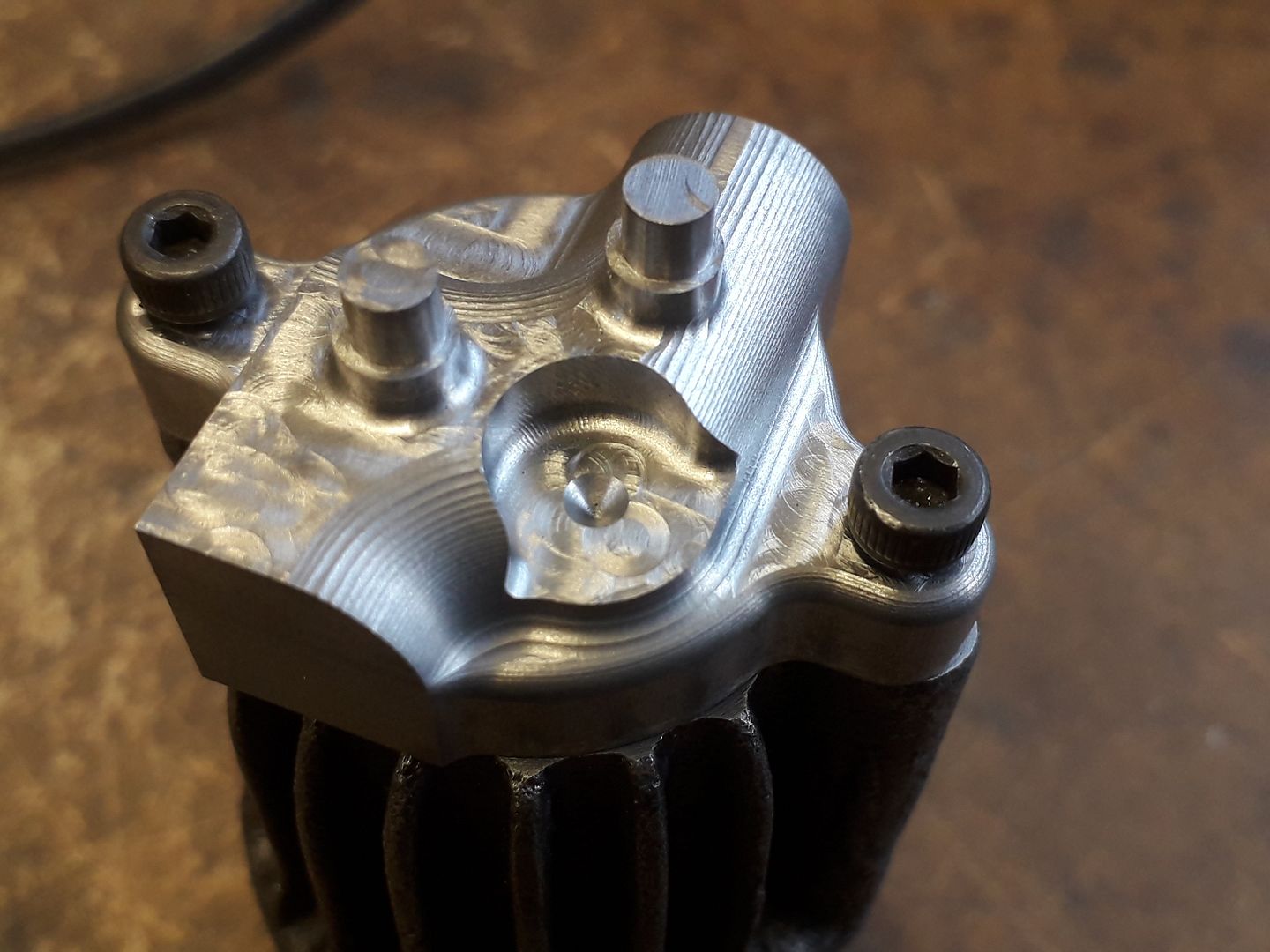

Posted by JasonB on 12/01/2020 16:23:14:

Having spent quite a while on Frday evening and even more on Saturday flicking teh RMC type A flywheel round I came to the conclusion that it is not going to work on propane instead of the now unobtainable MAPP gas I drew out a new head for it last night so it can be built as a 4-stroke, did the CAM this morning and then after lunch got the Sieg KX3 to spit out the new head in just over an hour. Still needs some holes here and there but will do those on the lathe and manual mill and then give it a lick with the needle files to get rid of the contour lines..

The bonus of CNC Jason that would have been a lot of work on a manual. What is the make up of MAPP that makes it different to propane and why no longer available..? Edited By Ron Laden on 15/01/2020 07:04:59 |

| Thread: Mini lathe amadeal cj18a help needed |

| 14/01/2020 16:05:33 |

Neil, unfortunately I dont have an answer to your problem other than to suggest you check the drive train from motor through to the chuck. It sounds as if the work you were doing at the time you lost drive was light duty and assuming there are no faults within the drive assy its strange that the motor drive pulley has failed yet again, it could be a faulty pulley of course but I wonder..? Have you checked the motor pulley to see if that is where the problem is..? When I had my CJ18 I stalled it twice whilst parting off and the second stall broke the plastic high/low spindle drive gears inside the head. It was quite some force as it broke off some teeth and split the main body of the gears and yet the small plastic motor drive pulley was fine including the moulded in key. Have a good look at the motor pulley and the rest of the drive to see if you can identify any problems which could cause the motor pulley to fail (if it has of course) it could be that the problem is elsewhere. Edited By Ron Laden on 14/01/2020 16:12:34 |

| Thread: Class 22 Diesel (next project) |

| 14/01/2020 14:52:13 |

I took a gamble and bought a cheap Chinese set of 4 radius edge cutters, cost £8 for the set 1/8, 1/4, 3/8 and 1/2 inch rads. The 20mm thick loco body cab/end plates have radiused edges which I was planning to cut and shape by hand but then thought it better and more accurate if I could machine to the basic shape and then hand finish. I didnt want anything expensive as the cutters will be seldom used if at all. I know router cutters are run at high speed and I only have a top speed on the mill of 2500 so that was the main worry, would they work at the lower speed..? Need not have worried as they work and cut just fine, tried some test cuts on a piece of Pine, unknown hardwood and MDF and they left a very clean finish even on the MDF which surprised me. So in this instance £8 well spent. 1/2 inch cutter below. |

| Thread: RMC Type-B Engine Build |

| 14/01/2020 14:31:45 |

Very nice, I am ok with the paint job, quite like it in fact makes a change from reds, greens and the like.I can only go by the pictures but I wouldnt say it looks lifeless in fact quite the opposite it has areas of reflected light and highlights, looks a very clean finish, well to me at least. |

| 14/01/2020 08:23:17 |

Nice work Jason, interesting, I picked up on the hand turning have never tried that will have to give it a go. I am guessing that the tool support bar is fixed to the tool post. The oil channel built into the nameplate is a neat idea I like that. |

| Thread: What Vice should I buy (2019) |

| 12/01/2020 10:24:52 |

I have a 80mm ARC versatile which I am really pleased with, great value for money. I have the swivel base removed but I have used it a couple of times. You certainly need to consider the size of vice, surprising how big a lump they are relative to the jaw size. |

| Thread: Australian Bush Fires |

| 12/01/2020 05:45:24 |

I am not upset just a bit of over reaction on my part I guess. I watched quite a bit of footage on the current situation yesterday and it is tragic beyond words just heartbreaking. Sorry Neil I didn't appreciate the humour at that time. |

| 11/01/2020 16:38:32 |

Posted by Neil Wyatt on 11/01/2020 14:29:24:

Two Rock Wallabies having a conversation: "Poor Bruce, he survived the drought, escaped the fire then a hundredweight of carrots fell out of the sky and crushed the poor b***r" Neil

I am surprised at you Neil, with you a chartered environmentalist and qualified ecologist I think the above is in bad taste and not funny at all if that is what its meant to be. Ron |

| 07/01/2020 16:34:57 |

Posted by Michael Gilligan on 06/01/2020 13:36:58:

Posted by Neil Wyatt on 06/01/2020 12:49:57:

Posted by XD 351 on 06/01/2020 11:35:54:

Climate change has little to do with the fires as they are part of the natural cycle of things here in Australia . […] Backburning is unpopular with most interests, not just tree-huggers; the problem is that 'saving wildlife and habitats' gets used as an excuse as it's convenient for many different interests. […] . I posted this on the ‘What did you do ... 2020’ thread, but I think it worth repeating: [quote] We are currently watching a wonderful series on BBC iPlayer First shown in March 2019, and narrated by Barry Humphries “ Australia: Earth’s Magical Kingdom “ [/quote] . For those that have access ... MichaelG. Yes it is a wonderful series Michael but now tinged with a feeling of "how it use to be" as a lot of what you see in the programmes will now be gone and some gone forever. I heard a news report today which said that of the millions of animals which have perished in the fires there will be some species which will in the long term never recover and face extinction. |

| Thread: The Workshop Progress Thread 2020 |

| 06/01/2020 09:14:24 |

Jason, I know it says so in the Preston video but the flywheel rim is a piece cut from a 7 inch diameter steel tube am I understanding that correctly, if so it must have been quite a thick walled tube..? |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in