regulator

leaking

| Eric Norris | 16/10/2013 12:29:41 |

| 1 forum posts | Help required, Can any one give advice on how to face off the regulator face in the cylinder bloke,on a 4inch Foster,as to take the whole bloke off is a major undertaking. Eric |

| JasonB | 16/10/2013 16:24:23 |

25215 forum posts 3105 photos 1 articles | Does it have a separate chest of is it in the bottom of a recess? If in a recess does the face sit proud or has the builder not run a relief cut around the edge? J Edited By JasonB on 16/10/2013 16:25:41 |

| Speedy Builder5 | 16/10/2013 16:26:43 |

| 2878 forum posts 248 photos | Look him straight in the eyes and say, You can't frighten me!! I guess that the spell checker is doing its worst here and we are talking cylinder block ? You could make an expanding soft mandrel, mount the mandrel between centres between centres. Then face RH, then LH ends. |

| JasonB | 16/10/2013 17:41:17 |

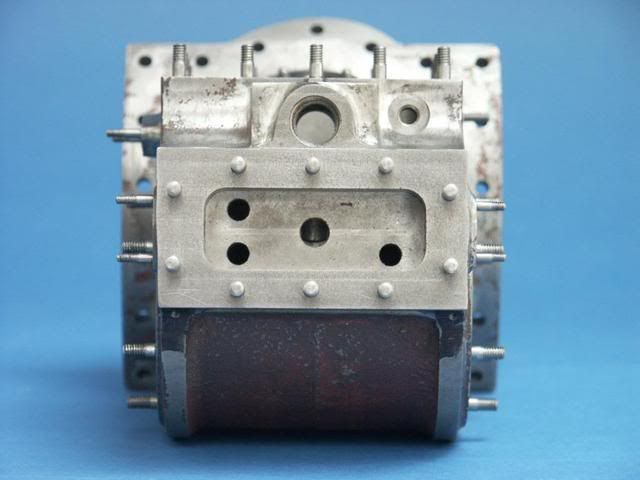

25215 forum posts 3105 photos 1 articles | Eric is asking about ways to do it without removing the Block from the boiler. Its also a flat surface at the bottom of a rectangular recess not a round loco type regulator, something like this which is actually my Fowler.

I am lead to believe there is a recess front and back of the port face. Back in the day the full size engines were done in situe with a planing machine that bolted to the cover studs and was hand cranked back an forth, the recess either end giving the tool something to run out into. Something could probably be knocked up to form guide rails and a tool holder run along these by hand, samething similar to a hand router using a HSS toolbit

Another way if there is not much to come off would be to make a holder for a dremel or die grinder so you could run back and forth using a small grinding stone at a constant depth, bit like cutting a mortice with an electric router. You would want to blue the mating parts after either method and hand scrape to a final finish or lap them in with Timesaver

Edited By JasonB on 16/10/2013 17:44:17 |

| Diane Carney | 16/10/2013 22:05:33 |

| 419 forum posts 11 photos | Posted by JasonB on 16/10/2013 17:41:17:

Back in the day the full size engines were done in situe with a planing machine that bolted to the cover studs and was hand cranked back an forth, the recess either end giving the tool something to run out into.

Back in the day ???? I have actually done this job on a full size engine. Not the regulator but the valve face. My does it make yer arm ache!! ... ha ha... Diane

|

| Ian S C | 18/10/2013 09:13:03 |

7468 forum posts 230 photos | Friend of mine has just replaned the valve face on his traction engine (full size), and made, and fitted new piston rings. He used the manually operated planer, reckoned his arm moved 39 kilometres. Ian S C |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in