Laser Tachometer

| The Merry Miller | 29/06/2012 10:57:59 |

484 forum posts 97 photos |

Morning all, Has any member purchased a tacho similar to the one in the image below (from e-bay I might add). If so, I'd appreciate comments on it positive or otherwise.

Len. P.

|

| Les Jones 1 | 29/06/2012 11:58:53 |

| 2292 forum posts 159 photos |

Hi Len, Les. |

| The Merry Miller | 29/06/2012 14:11:38 |

484 forum posts 97 photos | Hi Les, Was your tacho anything like the 2 in 1 version seen below. (on e-bay for about £14.50)

Len. P. |

| Les Jones 1 | 29/06/2012 14:41:44 |

| 2292 forum posts 159 photos |

Hi Len, Les. |

| Keith Long | 30/06/2012 12:55:50 |

| 883 forum posts 11 photos | Hi Len I bought one of the units as in your original post - it cost (from memory) £8.50 INCLUDING postage from Hong Kong! It works just fine for the use I have for it, checking lathe and motor speeds. I came with some sticky refelective strip to produce the marker pulse, but I've found there is usually enough contrast somewhere on the rotating bit that you don't need to bother. A dab of "snopake", white or black marker pen on a shiny shaft usually works just as well. I usually just point it at a flourescent tube as a quick calibration check and if I get a reading of 6000rpm+/- a bit I'm happy, as generally I'm not looking for measuring speeds to high accruracy. One point to watch is that there is no on/off switch on mine so the battery drains all the time, albeit at low level, so if you plan to use it infrequently it would pay to take the battery out for storage. Mine does exactly what I wanted it for, at a LOT less than I could build a unit for in terms of time and effort. Very satisfied. Keith |

| The Merry Miller | 30/06/2012 13:42:18 |

484 forum posts 97 photos | Thanks for your input Keith,

Les, does your Tacho have an on-off switch?

Len. P.

|

| Les Jones 1 | 30/06/2012 17:14:27 |

| 2292 forum posts 159 photos |

Hi Len, Les. |

| Adam Harris | 02/05/2019 18:43:07 |

| 533 forum posts 26 photos | So Len.P. did you buy one of those cheapo DT-2234C laser tachometers offered on ebay today around £9, and are you also as happy as Les with it? I wonder if it is a waste of time because the cheapest today on CPCFarnell is £37....Any body else have a cheap type to recommend? Edited By Adam Harris on 02/05/2019 18:49:43 |

| JasonB | 02/05/2019 18:49:04 |

25215 forum posts 3105 photos 1 articles | Len passed away a year or so ago. I have one of the tachos and it works OK for me on the odd IC engine or mill spindle. Edited By JasonB on 02/05/2019 18:54:43 |

| Adam Harris | 02/05/2019 18:51:54 |

| 533 forum posts 26 photos | Jason sorry to hear that. I just want out of interest to check my lathe spindles and milling spindle 0rpm - 3000rpm. Should I buy one of these DT-2234C tachos? |

| Adam Harris | 02/05/2019 19:01:10 |

| 533 forum posts 26 photos | Great video! So it works fine.I will take the plunge. Thanks |

| JasonB | 02/05/2019 19:01:13 |

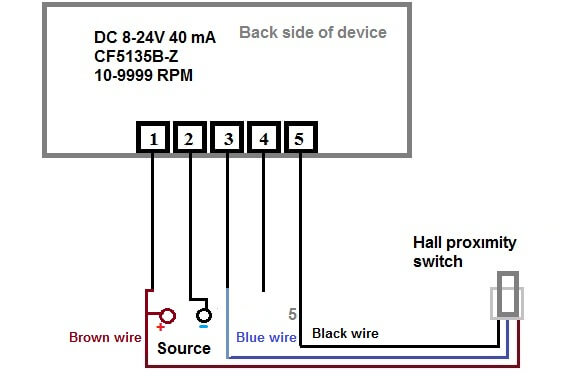

25215 forum posts 3105 photos 1 articles | Yes it will work for that, I've use dit a few times on the mill and to check the built in tacho on the lathe. It comes with some strips of reflective tape which may be needed depending on what surface you shine it on. Though for the same sort of outlay you can get the little tachos with proximity sensors and fit one of those which will give you a read out all the time. I have one on my mill now. This sort of thing Edited By JasonB on 02/05/2019 19:03:22 |

| Adam Harris | 02/05/2019 19:34:17 |

| 533 forum posts 26 photos | Thanks. And thanks for the nice video! |

| Tony Pratt 1 | 02/05/2019 19:40:36 |

| 2319 forum posts 13 photos | Posted by JasonB on 02/05/2019 19:01:13:

Though for the same sort of outlay you can get the little tachos with proximity sensors and fit one of those which will give you a read out all the time. I have one on my mill now. This sort of thing Hi, Has anyone got an idiots guide to wiring up the 'little tachos' as linked above? I have the display, ribbon cable & sensor, thanks in advance. Tony

|

| JasonB | 02/05/2019 19:42:26 |

25215 forum posts 3105 photos 1 articles |

You can also just read the numbers on it but a magnifying glass will help |

| Adam Harris | 02/05/2019 19:45:26 |

| 533 forum posts 26 photos | And do you have to fix the little magnet to the spindle ? How far must the proximity switch/sensor be to the magnet? Edited By Adam Harris on 02/05/2019 19:46:01 |

| Adam Harris | 02/05/2019 19:47:36 |

| 533 forum posts 26 photos | I've just bought the DT-2234C but might also try one those permanent installations |

| JasonB | 02/05/2019 19:58:00 |

25215 forum posts 3105 photos 1 articles | I just cleaned the spindle with acetone and then stuck the magnet on with Araldite, check magnet is the right way round first. Gap can be upto about 10mm but less is better.

|

| Tony Pratt 1 | 02/05/2019 20:11:45 |

| 2319 forum posts 13 photos | Jason B, Thanks for the excellent 'guide'!!! Tony |

| Adam Harris | 02/05/2019 20:26:45 |

| 533 forum posts 26 photos | I think it would be a useful tool when I am running the 3-phase 50 hz 400v motor (sadly non-dual voltage), with a 230v inverter setting inverter parameters pretending the motor is 230v 29hz - full torque up to 29hz but moving to higher frequency the torque declines such that one might not be able to reach the intended higher spindle speeds. This would be great for seeing real speed in such circumstances. Edited By Adam Harris on 02/05/2019 20:27:20 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in