Need to find 16 DP gears

To complete a change wheel set

| John Coates | 21/10/2011 12:06:58 |

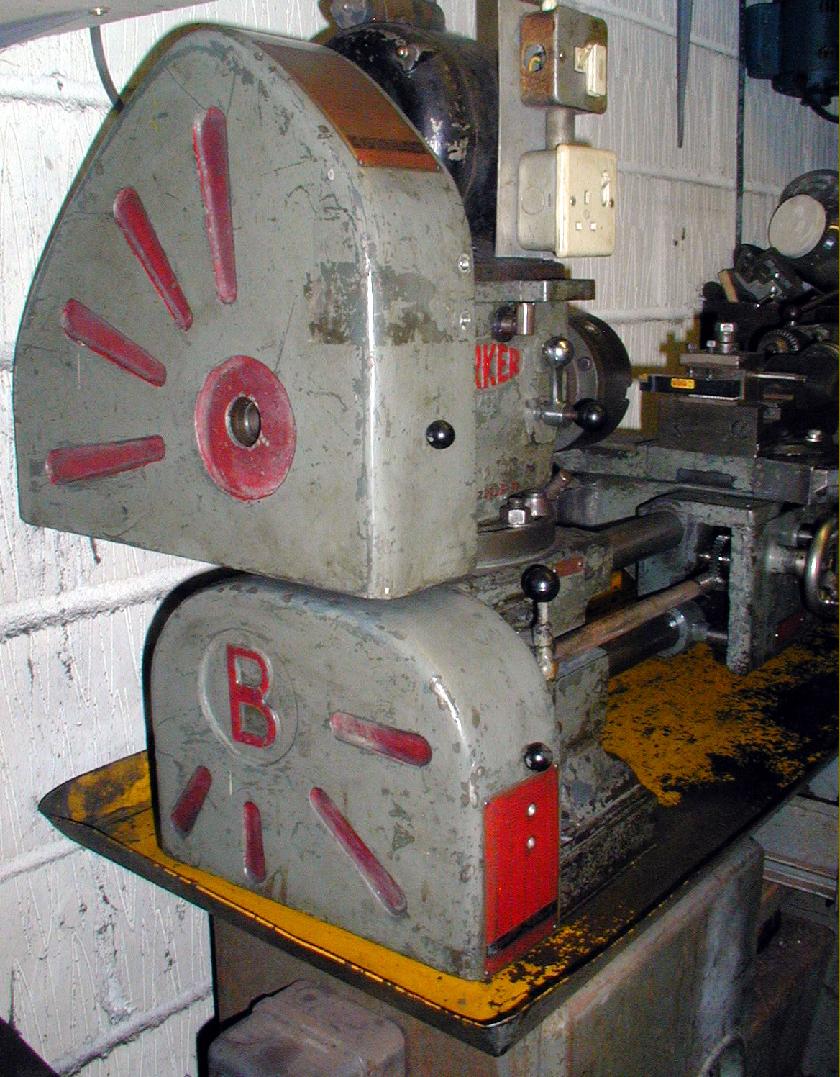

558 forum posts 28 photos | I have a Barker 5 x 24 lathe and have been contacted by another new owner and am trying to help him as his lathe is missing a lot of the change wheels.

I have established that the Barker uses 16 DP for the change wheels. Another model engineer with a Barker adapted a suitable change wheel from his scrap box to make a 60 tooth wheel for me so there are wheels from another lathe that can be sleeved to fit the Barker.

Does anybody know what lathe(s) uses 16 DP change wheels?

Thanks for any help on this one it really will be appreciated

John |

| ady | 21/10/2011 12:20:23 |

| 612 forum posts 50 photos | Drummond use 14dp I just buy myford (20dp?) stuff and mix and match, the main thing is after drilling a hole the gears fit straight on to the studs on my unit. If I start a production line cranking out 5000 units a day I might start to worry about the DP. Edited By ady on 21/10/2011 12:21:56 |

| John Stevenson | 21/10/2011 12:25:29 |

5068 forum posts 3 photos | Early Colchester and Harrison, later ones used module gears. Colchester and Harrison usually have a 6 splined centre. No good buying Myford if you have to run with existing gears. John S. Edited By John Stevenson on 21/10/2011 12:26:22 |

| ady | 21/10/2011 12:29:20 |

| 612 forum posts 50 photos | Does your barker have a leadscrew reversing gearbox? I wouldn't mind a wee look at what's in there if you ever open it up, if its not too complicated it would make a darned interesting project. piccy nicked from Tonys superlative site. |

| John Coates | 21/10/2011 12:37:05 |

558 forum posts 28 photos | Posted by ady on 21/10/2011 12:29:20:

Does your barker have a leadscrew reversing gearbox?

Yes it does. The whole lathe needs an overhaul (clean, strip, paint, lubricate) as although it performs well I want it to look "newer" as I'll be keeping it.

Myself and this new owner have ambitious plans to help each other and get our lathes in tip top condition and complete so I'm sure the refurbishment will happen. If we get a basket case to cannibalise then the reversing gearbox can be accessed sooner  |

| John Coates | 21/10/2011 12:46:52 |

558 forum posts 28 photos | Here we go. I found the original photo my friend sent me about the adapted changewheel. The adapted one is on the left and an original is on the right

Anybody recognise it?

Edited By John Coates on 21/10/2011 12:47:22 |

| John Stevenson | 21/10/2011 13:02:03 |

5068 forum posts 3 photos | Probably the helical change wheels off a dividing head. What sizes are you looking for ? John S. |

| John Coates | 21/10/2011 13:07:17 |

558 forum posts 28 photos | Posted by John Stevenson on 21/10/2011 13:02:03:

Probably the helical change wheels off a dividing head.

What sizes are you looking for ?

Don't know John I'll get in touch with him over the weekend. They are straight cut btw not helical (sorry if that sounds dumb but I am a newbie!)

If ones from another lathe cannot be found then cutting new ones is an option (but then we have to get a dividing head to use my wheels with  ) ) |

| John Stevenson | 21/10/2011 13:13:23 |

5068 forum posts 3 photos | When I said helical I meant the drive wheels that go between a dividing head and the leadscrew on a milling machine to allow the dividing head to rotate as it moves along the bed to cut helical gears. Not that the gears were helical, sorry I was a bit too terse with my reply. I may have some 16DP gears that came off a scrapped Colchester John S. |

| John Coates | 21/10/2011 13:20:48 |

558 forum posts 28 photos | Ah just realised I had better mention that Barker changewheels rise by fours

The full set is 20, 24, 32, 36, 38, 40, 44, 48, 52, 54, 56, 60, 80

That could have an influence on the outcome! |

| Gray62 | 21/10/2011 17:03:07 |

| 1058 forum posts 16 photos | Take a look at HPC Gears they produce good quality gears at reasonable prices and can do 16DP.

regards

Graeme

|

| John Coates | 21/10/2011 17:18:24 |

558 forum posts 28 photos | Thanks Graeme. You're the second person to point me in their direction. But the smaller ones will need boring out as standard Barker ones are 5/8ths and the HPC ones don't become that bore until 36 teeth

At least we have a solution if all else fails |

| John Stevenson | 21/10/2011 20:48:59 |

5068 forum posts 3 photos | HPC's gears are all 20 degree pressure angle, chances are the Barker will be the old fashioned 14.5 degree. John S. |

| John Coates | 21/10/2011 21:42:07 |

558 forum posts 28 photos | Well it looks like we have three to try:

Smart and Brown Model M

Colchester Bantam

Drummond round bed

Thanks to everyone who replied

|

| ady | 22/10/2011 00:13:33 |

| 612 forum posts 50 photos | Some huge drummond round bed tooling sets have come up on fleabay recently, there are still a lot around. |

| John Coates | 22/10/2011 09:59:18 |

558 forum posts 28 photos | And to add to the list is the Raglan 5"

Looks like I'll need to set some searches up on fleabay  |

| Keith Long | 22/10/2011 17:28:16 |

| 883 forum posts 11 photos | Hi John If you want gears to run in mesh with existing 16dp wheels then take Drummond OFF the list as they are 14dp. You might get them to transmit drive with a 16dp but you run the real risk of damaging both. If you are thinking of getting a FULL set of gears, the ones for the early Drummond round bed also rise in 4s (10tpi lead screw) the standard set being, 20,20 24,28,32.36.40 44 and 64 with the extras for metric threads being 25,35,45,50 and 63. The gears for other Drummonds, later round bed, "B" type flat bed and "M" type rise by 5s from 20 to 50 or 65 with additional intermediate gears to give the metric threads (26,38,63,66,73 depending on lathe model) The Drummond gears will also be a bigger diameter for the same number of teeth than the Barker gears which may give problems with assembling the trains that you will need. Myford gears being smaller (20dp) will probably be a lot easier to accommodate as well as being more readily available, but again you'll need to get hold of a full set. I think some makers used 18dp (Boxford?) and these may be available in sets. If you want to buy odd wheels to run with existing gears you really do need to get 16dp and the correct pressure angle - virtually certain to be 14.5 degree. Keith |

| John Coates | 22/10/2011 21:49:44 |

558 forum posts 28 photos | Thanks Keith

Will not bother looking for Drummonds then

John |

| Alan Kiff | 13/11/2011 17:20:30 |

| 1 forum posts | Hi, I have both 14 and 16DP gears in sizes from 14 to 84 tooth (14 dp) and 12 to 112 tooth (16dp). These were manufactured for Bonds of Euston Road and are 20 deg. pressure angle. Send me a PM if you are interested. Regards Alan |

| Chris S1 | 12/12/2011 09:51:39 |

| 2 forum posts | Hi - sorry to be two months late - I've only just noticed this subject in your forum when trying to find out about other changewheels.

Atlas lathe 9, 10 & 12" use changewheels of 16DP and a pressure angle of 14.5 degrees. Face width has varied a little but mostly 0.375" and a bore of 0.753" and a double keyway 0.1875" wide. The gears are apparently interchangeable across these three Atlas lathes although the central boss on those from 9" is thinner.

See http://www.lathes.co.uk/atlas/index.html - about 1/4 way down.

I have three unwanted and unidentifed changewheels appear identical to my Atlas type in all major dimensions but lack the four piercings made in the gear web for appearance purposes. I'm fed up with them being around though.

They are 48, 56 & 64 teeth. They look fine to my untrained eye but are obvioulsy used.

If anyone needs them I'd be pleased to post them for cost of UK postage plus £5 for each gear which I'd pass to Cancer Research UK once you've confirmed they were what you expected.

I hope this message is acceptable to the invigilators - if not, my apologies for the error.

Cheers

Chris |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in