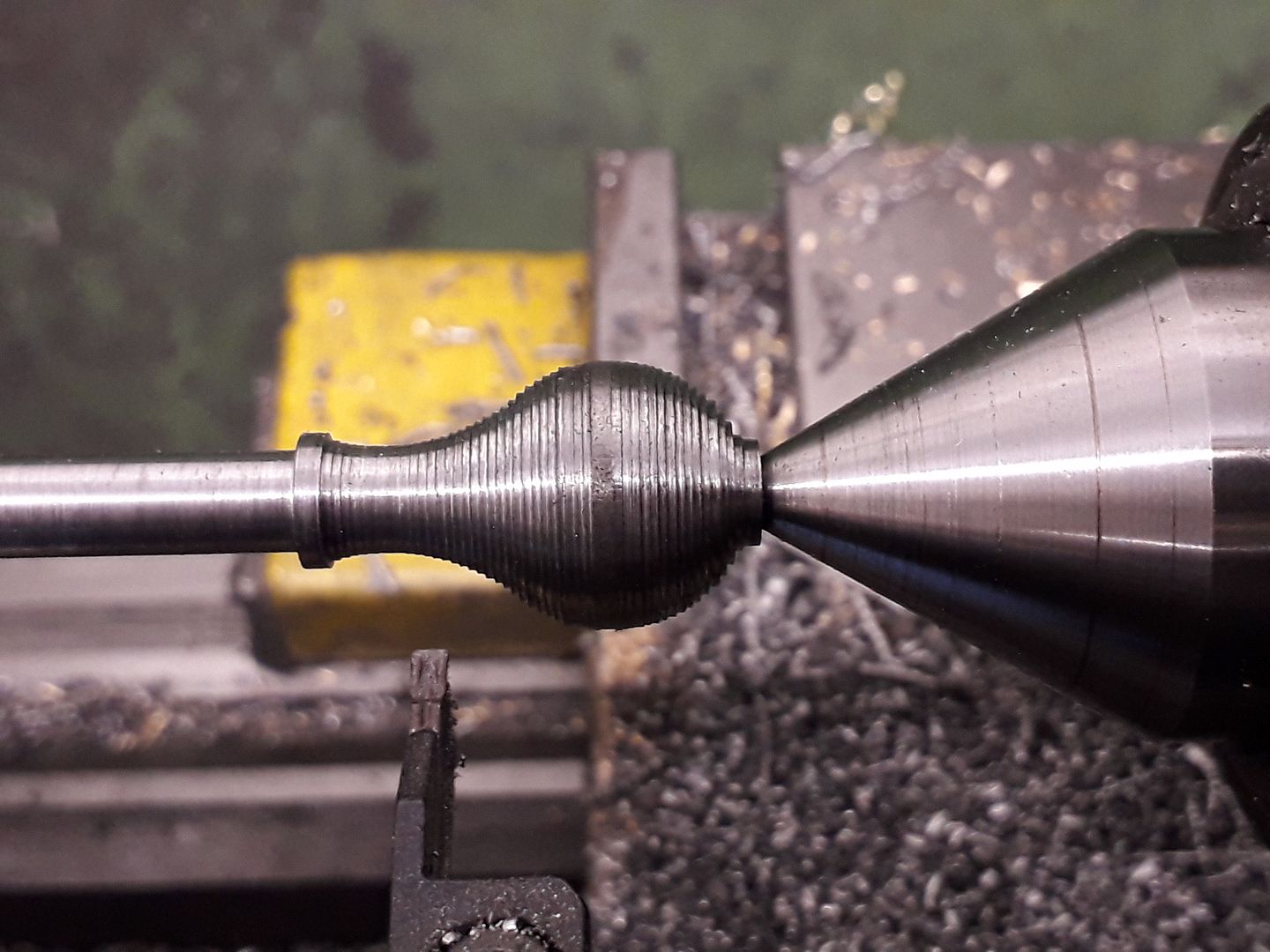

How would you make this part?

A work-holding challence par excellence!

| Jelly | 16/03/2023 17:36:25 |

474 forum posts 103 photos | So I was looking for something on one of my external HDD's and happened across the 3d model of the main body of something I made as a gift for a friend years ago (there are some other parts which turn it into a little bird). I've just produced a little drawing of it as it's a really interesting part, which produces lots of challenges: The one I made was actually ½ scale, and turned from a cylindrical piece of brass on a M6 threaded arbour, the curves roughed in with chamfers, and the final shape generated with a (gigantic) carbon steel form tool shaped to produce the full profile. That very direct approach was easy on the work-holding front, but an absolutely bonkers way to go about it in just about every way... Something which I came to fully appreciate as the process resulted in innumerable scrapped parts, several snapped arbours and at least one malformed brass bird being launched bodily across the workshop. I quite fancy making another full-size one for myself, but learning from the previous failures, I can recognise that there's a risk of having a 1kg hunk of brass launched at me, which I'm not really up for. Thankfully in the intervening years since I made the last one, I have also become slightly more imaginative (to go with the risk aversion) and have been able to come up with a few different approaches using to try which I think would result in a decent outcome, all of which involve making a jig/chuck which can hold onto a sphere securely, and pose their own problems in terms of driving the workpiece and/or marring the surface of a finished part due to clamping pressure I am however curious how others would approach this, because on first inspection it's far from simple to even hold on to the thing. |

| SillyOldDuffer | 16/03/2023 17:51:37 |

| 10668 forum posts 2415 photos | Am I allowed to make it in two parts, super-glued together? If so, I think access to the flat between the head and body would reduce the weight and simplify the holding problem. The angled holes suggest a rotary table and milling machine. I agree it's a challenge though, every time I make things like that there's high-scrappage! Dave

|

| Dave S | 16/03/2023 17:54:08 |

| 433 forum posts 95 photos | Start with bar, bosh in m12 thread, thread onto m12 arbour, turn features. use m12 to fixture in mill for odd angled holes Dave |

| Tony Pratt 1 | 16/03/2023 18:09:58 |

| 2319 forum posts 13 photos | I was thinking the same as Dave S, the M12 thread makes it not too difficult using a radius turning attachment. Tony |

| Jelly | 16/03/2023 18:14:47 |

474 forum posts 103 photos | Posted by Dave S on 16/03/2023 17:54:08:

Start with bar, bosh in m12 thread, thread onto m12 arbour, turn features. use m12 to fixture in mill for odd angled holes Dave In fairness actually, the M12 thread would be substantially stronger than the M6 thread used to turn the half-sized one and not using a full profile form tool would also reduce the cutting forces substantially... I don't think I've seen a ball turning attachment with a 60mm capacity before though, but once one was built, it would be substantially more useful than a fixture to hold 60mm spheres or 40mm hemispheres. Edited By Jelly on 16/03/2023 18:24:09 |

| JasonB | 16/03/2023 18:43:50 |

25215 forum posts 3105 photos 1 articles | Thread end of stock, stick it on an arbor and two setups of my ball turner and that's the lathe work dine. Transfer arbor to ER block and setup on mill for beak and tail holes. My ball turner is OK for those sizes and more. easier if it were wood, I've done a few birdies like that simple hand turning so I suppose you could use a graver on metal after roughing out with a few CAD derived co-ordinates. It's quite easy to do

Edited By JasonB on 16/03/2023 18:47:36 |

| JasonB | 16/03/2023 19:22:05 |

25215 forum posts 3105 photos 1 articles | Regarding the weak M6 arbor. Best option would probably have been to form the "head" while holding by the OD of the stock in a 3-jaw chuck. Then mount on the 6mm arbor and use a female ctr to add support to the "head" while the "body" is machines. Or you could leave a pip on his head for a small ctr drilled hole for use with the rotating ctr and machine off the pip once the larger parts have been machined |

| Andrew Johnston | 16/03/2023 19:39:15 |

7061 forum posts 719 photos | Hydraulic copy unit: Turn the larger ball and a parallel section first, and drill/tap the M12 hole, and part off. Locate larger ball in an aluminium cup chuck held with an M12 bolt. Turn the smaller hemisphere. For drilling/tapping the smaller holes use a universal dividing head with item mounted on a cylinder with an M12 bolt. Andrew |

| Howard Lewis | 16/03/2023 21:19:57 |

| 7227 forum posts 21 photos | The Repton Radius Turning tool claims that it can accomodate up to 60 mm diameter. Howard |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in