Flycutting

| peter spain | 18/11/2022 00:11:07 |

| 3 forum posts | Hi All Thanks to all for the kind responses to my scaling question.All very helpful. Recently i have been trying out fly cutting mainly to try to reduce the expense of having to buy milling cutters. I made a tramming bar for my Axminster mill and set the mill up to within a .001.I have an understanding of the tool geometry but still have this problem of cutting on the backstroke if that makes sense.All ok on ally or brass but it doesnt like steel.Also i can only use very fine cuts which is time consuming. Any ideas ? |

| Nigel Graham 2 | 18/11/2022 00:29:24 |

| 3293 forum posts 112 photos | Even 0.001" out of perpendicular is still enough to cut on the "backstroke", if the head is angled "backwards" relatively to the table travel, and to produce a concave result up to 0.001" deep. I do use fly-cutting, sometimes, but don't really like doing so as it hammers the machine very heavily. It is all right for very fine finishing work but not bulk metal removal, except perhaps on a hefty great industrial machine with power-feeds, and made to handle such arduous duty. My preference is to use fluted cutters... and re-sharpen them! |

| Hopper | 18/11/2022 01:09:29 |

7881 forum posts 397 photos | Milling cutters are so cheap from Aliexpress.com why bother with flycutting in this day and age? I don't even bother to sharpen them. Regard them as consumables at today's prices. Edited By Hopper on 18/11/2022 01:10:01 |

| JasonB | 18/11/2022 07:03:55 |

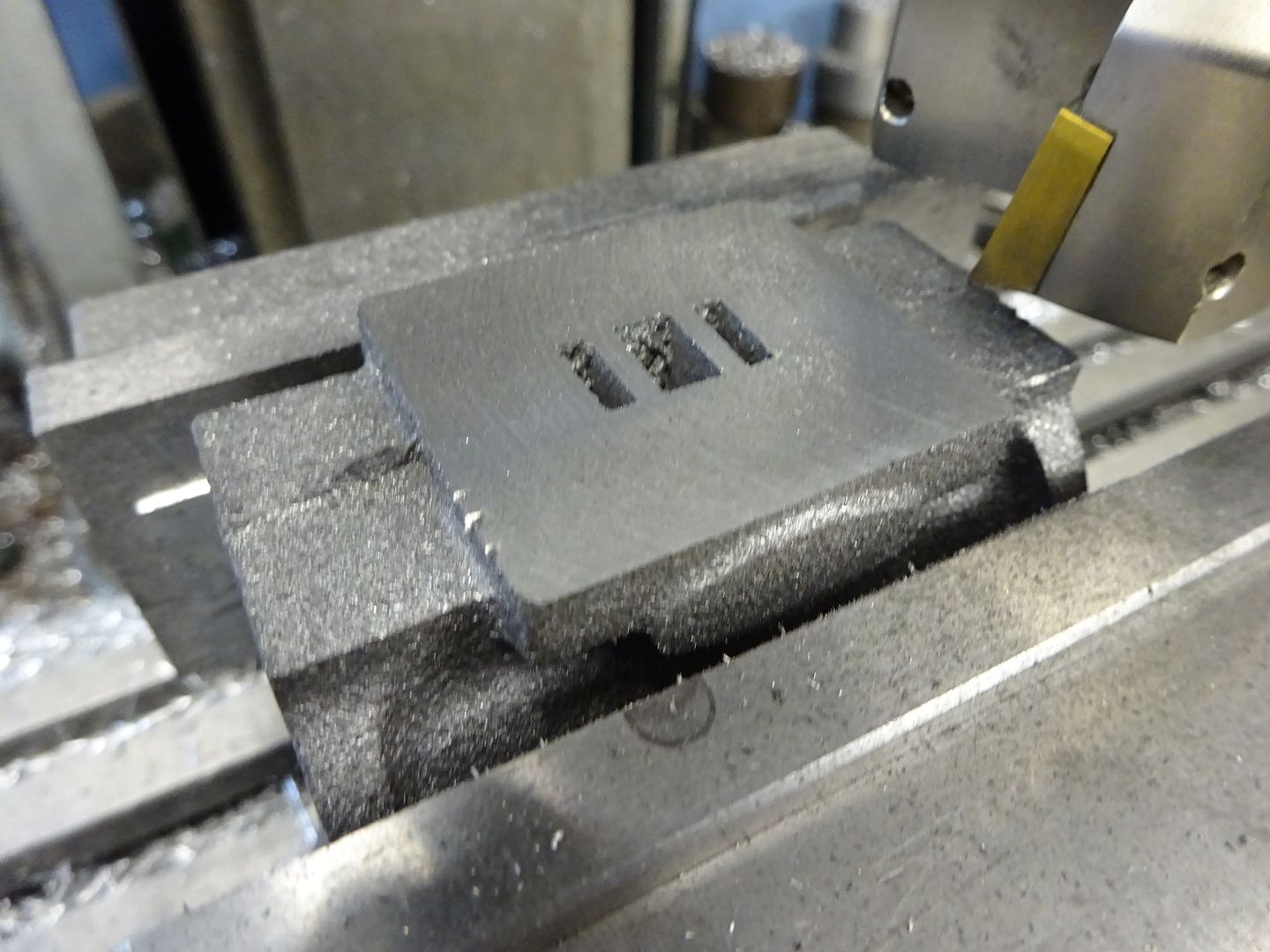

25215 forum posts 3105 photos 1 articles | What mill do you have? On the smaller benchtop mills you are only likely to take off say 1mm on the non ferrous metals and up to 0.5mm on steel depending on diameter of the swept circle. Correct geometry of the cutter also plays a part, often those not use dto grinding a tool will end up with little or no clearance so the edge of teh tool rubs rather than cuts and it will tend to get pushed away particularly by harder material rather than cut. I used to flycut quite a lot but now tend to reach for an insert shell or face mill. Apart from not needing sharpening as much as HSS you can run them faster and feed 4-6 times faster than a single point tool which makes it easier to keep a constant feed. Bit of flycutting on the SX2.7, EN3 steel |

| Ramon Wilson | 18/11/2022 08:39:21 |

1655 forum posts 617 photos | Unless a flycutter is set such that it cuts only on the front stroke you will get this situation. Doing that increases the other problem with flycutting, that of a concave surface. There is also the temptation to make the fly cutter as large as possible to cover the area machined in one sweep. This in itself slows things down as the diameter requires a slow rotational speed which in turn has an effect on surface speed. Depth of cut is also minimal. It is much better to mill a flat surface with smaller cutters but I appreciate your concern regarding the cost. Making a much smaller diameter fly cutter is one answer - you can convert an old, say 1/2 end mill or slot drill by grinding the teeth, save one, back and sharpening the remaining tooth much like you would a flycutter tool. This works but of course again only for shallow depths but everything speeds up considerably. Yes the surface finish doesn't not look so nice to some eyes but it will be much flatter and achieved far quicker. I'm fortunate enough to have a variety of cutters to call on but personally I mostly use HSS 6mm FC3 'Throw Away' cutters for this type of operation, reasonably cheap and readily available compared with standard end mills/slot drills. Carbide cutters will give you a longer life but are easily chipped/shattered and not likely to be reclaimed by the kit in the average workshop so I avoid them save for when a situation calls for it. There is nothing wrong in flycutting but it's not the easy alternative that it's sometimes seen as. Best - Tug

PS I am not suggesting by my first statement above that this is how a fly cutting operation should be set up - merely pointing out that this is the only way to eliminate cutting on the backstroke which, due to the nature of the operation, even with perfectly trammed mill, will occur - the larger the diameter the more it will do so. Edited By Ramon Wilson on 18/11/2022 08:42:51 |

| JasonB | 18/11/2022 09:21:30 |

25215 forum posts 3105 photos 1 articles | It is possible to tram a mill so that leading and trailing edges cut equally which gives an almost holographic effect but it is very hard to get right. So if you do find one one side cuts deeper than the other you can make use of that by feeding so that the trailing edge takes a fine finish cut after the leading edge has removed the bulk. Though as Ramon says this can leave a very minute concave surface which is why I mostly use the flycutter or insert head to get rough sawn blocks down to a usable and square size then where a very flat surface is needed change to a SHARP milling cutter and make a series of passes, typical would be this Stuart cylinder where it was roughed out with inserts which will not get blunted by any skin or chilled areas, then finished with a 6mm 3-flute cutter which will have less work to do and keep replacement costs down

Although I showed quite a large flycutter in the earlier video my usual weapons of choice are from a set of three which I think have heads of approx 20, 30 and 40mm. the 30 get used the most with 6mm HSS shown here being used as a single point tool to cut moulded profiles and fillets. You can spin these faster than a large one without over speeding the cutting tip so feed as also faster Edited By JasonB on 18/11/2022 09:22:27 |

| bernard towers | 18/11/2022 09:48:11 |

| 1221 forum posts 161 photos | Now who said shapers were out of date? |

| noel shelley | 18/11/2022 10:24:08 |

| 2308 forum posts 33 photos | Well done Bernard , you read my thoughts and beat me to it ! Noel. |

| Andrew Johnston | 18/11/2022 10:37:54 |

7061 forum posts 719 photos | I don't bother with flycutting flat surfaces for the reasons given above. I find that milling cutters give flatter, and better finished, surfaces: I only use flycutting when I need a large curved surface: In the above the DOC was 40 thou and feed was 8 thou per rev. The flycutter is homemade with a HSS toolbit. Andrew |

| Ramon Wilson | 18/11/2022 11:31:38 |

1655 forum posts 617 photos | Well what's a milling machine if it isn't a shaper Bernie Lovely finish on that example Andrew - is that copper or phosphor bronze? Nice set up in that last pic too but you have to admit you have a very sturdy machine there with plenty of power to boot for a good cut like that

Tug Edited By Ramon Wilson on 18/11/2022 11:34:15 |

| Bazyle | 18/11/2022 13:50:58 |

6956 forum posts 229 photos | Do you get the problem left to right and right to left? If so it is not the tramming (not all) and indicates flexing in the mill owing to too deep a cut or incorrectly sharpened tool. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in